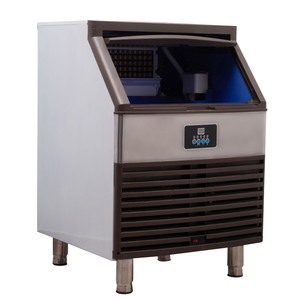

Undercounter Cube Ice Machine

1/2

1/2

1/23

1/23

1/24

1/24

CN

CN

1/58

1/58

1/27

1/27

CN

CN

1/22

1/22

About undercounter cube ice machine

Where to Find Undercounter Cube Ice Machine Suppliers?

China remains the central hub for undercounter cube ice machine manufacturing, with key production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, stainless steel stamping, refrigeration system assembly, and final product testing. Ningbo and Shanghai in Zhejiang and Jiangsu respectively serve as primary export centers, leveraging proximity to major ports like Ningbo-Zhoushan and Shanghai Yangshan for efficient global distribution.

The industrial ecosystem supports both standardized and customized production, with many suppliers operating facilities exceeding 5,000m² equipped with automated welding, CNC bending, and environmental simulation testing chambers. This integration enables lead times of 25–40 days for bulk orders and reduces component procurement costs by 18–25% compared to non-specialized manufacturers. Buyers benefit from concentrated technical expertise, with over 70% of suppliers offering OEM/ODM services including logo imprinting, color variation, and control panel customization.

How to Choose Undercounter Cube Ice Machine Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Technical and Compliance Verification

Confirm adherence to international standards such as CE, RoHS, and ETL certifications—essential for market access in Europe and North America. Evaluate refrigeration systems for compliance with energy efficiency regulations (e.g., DOE in the U.S.). Request documentation on compressor type (typically R600a or R404A refrigerants), condenser configuration (air-cooled, front-ventilated), and daily ice yield accuracy verified under ISO 8513 test conditions.

Production and Quality Assurance Capacity

Assess operational scale and process control through the following indicators:

- Minimum factory area of 3,000m² for sustained volume output

- In-house capabilities in sheet metal processing, refrigerant charging, and leak detection

- Presence of dedicated QC teams conducting 100% functional testing pre-shipment

Cross-reference on-time delivery rates (target ≥98%) and reorder frequency to validate reliability. Response time under 6 hours indicates strong customer service infrastructure.

Transaction and Risk Mitigation Protocols

Utilize secure payment mechanisms such as trade assurance or escrow services. Prioritize suppliers with verifiable export histories and third-party inspection acceptance. Conduct sample testing to verify ice clarity, cycle consistency, and noise levels (should not exceed 49 dB). For customized units, request 3D drawings or prototype validation before mass production.

What Are the Best Undercounter Cube Ice Machine Suppliers?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | MOQ Range |

|---|---|---|---|---|---|---|---|---|

| Ningbo Yingyi International Trade Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | US $210,000+ | 100% | ≤2h | 27% | Color, size, logo, packaging, label, graphic | 1–10 pcs |

| Suzhou Seitek Co., Ltd. | Jiangsu, CN | Custom Manufacturer | Not specified | 100% | ≤21h | Not available | Color, material, size, logo, packaging, label, graphic | 80–198 sets |

| Shanghai Snowman Electrical Equipment Co., Ltd. | Shanghai, CN | Not specified | US $40,000+ | 100% | ≤6h | <15% | Not specified | 1 pc |

| Guangzhou LVNI Hotel Supplies Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $60,000+ | 100% | ≤4h | 33% | Color, size, logo, packaging, label, graphic | 1 unit |

| Shanghai Langtuo Intelligence Technology Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $5,000+ | 100% | ≤13h | 50% | Color, material, size, logo, packaging, label, graphic | 1–5 sets |

Performance Analysis

All five suppliers demonstrate perfect on-time delivery records, indicating strong logistical discipline. Ningbo Yingyi and Guangzhou LVNI stand out for low MOQs (1 piece) and robust customization options, making them ideal for small businesses or niche market entrants. Shanghai Langtuo exhibits the highest reorder rate (50%), suggesting strong customer satisfaction despite a lower online revenue footprint. Suzhou Seitek, while requiring high MOQs (80+ sets), offers full material and design customization suited for large-scale commercial deployments. Buyers seeking rapid response should prioritize Ningbo Yingyi (≤2h) or Guangzhou LVNI (≤4h).

FAQs

How to verify undercounter ice machine supplier reliability?

Validate certifications (CE, RoHS, ETL) through official databases. Request evidence of quality management systems (e.g., ISO 9001) and conduct virtual audits of production lines. Analyze transaction data including confirmed order volume, buyer reviews, and dispute resolution history via trusted B2B platforms.

What is the typical lead time for bulk orders?

Standard lead time ranges from 25 to 40 days after deposit confirmation, depending on order complexity and production load. Custom configurations may extend timelines by 10–15 days. Air freight samples typically arrive within 7–10 days globally.

Can suppliers accommodate low minimum order quantities?

Yes, several suppliers—including Ningbo Yingyi, Guangzhou LVNI, and Shanghai Snowman—offer MOQs as low as 1 unit, facilitating pilot testing and small business procurement. High-volume manufacturers may require 80+ units per order.

Do manufacturers provide customization for commercial clients?

Most suppliers support OEM/ODM services, including custom branding, color finishes, cabinet dimensions, and control interface design. Material upgrades (e.g., thicker gauge stainless steel) are available upon request, particularly from custom manufacturers like Suzhou Seitek and Guangzhou LVNI.

What payment and shipping terms are common?

Common payment methods include T/T, L/C, and platform-backed transactions with trade assurance. FOB terms are standard; CIF can be arranged for full-container loads. Sea freight is optimal for orders over 10 units, while air shipping suits urgent samples or small batches.