Universal Robots Machine Tending

CN

CN

CN

CN

CN

CN

CN

CN

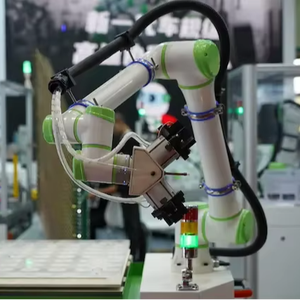

About universal robots machine tending

Where to Find Universal Robots Machine Tending Suppliers?

China’s industrial automation sector has established a robust ecosystem for machine tending robotics, with key supplier clusters in Shandong, Jiangsu, and Shanghai. These regions host integrated manufacturing networks that combine precision engineering, electronics assembly, and robotic system integration. Shandong specializes in mid-to-high payload collaborative robots (cobots), leveraging local expertise in mechanical design and control systems. Shanghai-based suppliers focus on application-specific configurations, offering advanced programmability and integration with CNC machinery. Jiangsu contributes through component-level supply chain efficiency, particularly in power transmission and cabling subsystems critical for reliable robot operation.

Suppliers in these hubs operate within vertically aligned ecosystems where motor manufacturers, gripper developers, and software integrators are co-located, reducing lead times by up to 30% compared to fragmented international sourcing. Average production cycles for standard cobot units range from 15–25 days, with customization adding 7–14 days depending on complexity. Buyers benefit from scalable output—verified suppliers report monthly capacities exceeding 200 units—and access to modular platforms compatible with Universal Robots’ UR5e, UR10e, UR16e, and UR20 series.

How to Choose Universal Robots Machine Tending Suppliers?

Evaluate potential partners using the following criteria to ensure technical reliability and transaction security:

Technical Compatibility & Integration

Confirm compatibility with Universal Robots’ ecosystem, including supported payloads (5–30kg), reach ranges (850–1750mm), and software protocols. Suppliers must provide documentation on end-effector integration (e.g., pneumatic or electric grippers), safety-rated monitoring, and compliance with ISO/TS 15066 for collaborative applications. Verify support for digital twin simulation, path programming interfaces, and remote diagnostics.

Production and Customization Capability

Assess supplier infrastructure based on the following benchmarks:

- In-house engineering team capable of fixture design and workflow optimization

- Minimum factory area of 3,000m² for dedicated robotic assembly lines

- Customization options including color coding, labeling, packaging, software presets, and protective covers

- Support for both single-unit sets and bulk orders (e.g., dozen-level MOQs)

Cross-reference claims with response time metrics (target ≤4 hours) and on-time delivery performance (ideally 100%). Prioritize suppliers offering video audits or facility walkthroughs to validate production scale.

Quality Assurance and Transaction Security

Require evidence of quality management systems such as ISO 9001. While not all suppliers list formal certifications, consistent on-time delivery (≥97%) and low reorder rates (<20%) indicate operational stability. Use secure payment mechanisms like escrow services and request pre-shipment inspection rights. For used or refurbished units, demand detailed usage logs, refurbishment reports, and functional testing records before acceptance.

What Are the Best Universal Robots Machine Tending Suppliers?

| Company Name | Location | Verified Status | Product Range | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Gongboshi Robot Technology Co., Ltd. | Shandong, CN | Multispecialty Supplier | UR15, UR16e, UR20, UR30 (up to 30kg payload) | 100% | ≤4h | <15% | US $20,000+ | Color, material, size, logo, packaging, label, graphic |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Shanghai, CN | Multispecialty Supplier | UR5e, UR10e, UR12e, UR16e, 6-axis cobots | 100% | ≤7h | 20% | US $50,000+ | Payload, reach, gripper, control panel, software, explosion-proof cover, robot track |

| Jiangsu Greatway Electrical Co., Ltd. | Jiangsu, CN | Not Specified | UR5, UR10, UR20 (15–17.5kg payload) | 100% | ≤4h | - | - | Limited (gripper, dispensing modules) |

| Zhejiang Bogang Intelligent Technology Co., Ltd. | Zhejiang, CN | Not Specified | Used ABB and industrial arms (non-Universal branded) | 100% | ≤7h | - | US $700+ | None reported |

| Shandong Rayman Machinery Co., Ltd. | Shandong, CN | Custom Manufacturer | Generic universal robot arms (4–11kg payload) | 66% | ≤2h | <15% | US $40,000+ | Fixture, color, material, size, logo, packaging, label, graphic |

Performance Analysis

Gongboshi Robot Technology and Xiangjing (Shanghai) demonstrate strong alignment with industrial automation demands, offering high-payload models (UR16e, UR20, UR30) at competitive price points ($22,000–$63,000). Both maintain 100% on-time delivery and offer extensive customization, making them suitable for OEM integration and turnkey machine tending cells. Jiangsu Greatway focuses on component-level support but lacks detailed customization reporting. Zhejiang Bogang offers significantly lower-cost used industrial robots ($3,980–$5,980), though these are not Universal Robots-branded and may require substantial reconditioning. Shandong Rayman provides budget-friendly programmable arms ($4,100–$11,000), but its 66% on-time delivery rate indicates fulfillment risk despite rapid response times.

FAQs

What is the typical minimum order quantity (MOQ) for universal robot machine tending systems?

Standard MOQ is 1 set for new cobot systems. Some suppliers offer dozen-level pricing for compact models (e.g., UR15, UR16e variants), indicating bulk procurement opportunities. Used systems typically have an MOQ of 1 unit.

What are common customization options available?

Suppliers offer configurable elements including robot arm color, labeling, packaging, software presets, gripper types, control panels, protective enclosures, and mounting fixtures. High-end providers support integration with conveyor systems, vision guidance, and safety interlocks.

Are there differences between new and used machine tending robots?

Yes. New systems from authorized or compatible suppliers include warranties, full documentation, and guaranteed performance parameters. Used units, while cost-effective, may lack service history, require recalibration, and pose integration challenges due to outdated firmware or wear on joints and motors.

How do pricing tiers reflect capability differences?

Entry-level generic arms range from $4,000–$11,000 and suit basic handling tasks. Mid-tier UR5e/UR10e-compatible systems ($18,000–$26,000) support precise CNC tending. High-payload UR16e/UR20/UR30 models ($32,000–$63,000) are engineered for heavy machining environments requiring extended reach and durability.

What logistics and export terms should buyers confirm?

Verify FOB or CIF shipping terms, container loading specifications, and export documentation (commercial invoice, packing list, bill of lading). Ensure suppliers can comply with destination-country electrical safety standards (CE, UL) and provide necessary conformity declarations for customs clearance.