Universal Robots Palletizing

Top sponsor listing

Top sponsor listing

1/11

1/11

CN

CN

1/12

1/12

1/5

1/5

1/5

1/5

1/14

1/14

1/18

1/18

1/28

1/28

1/18

1/18

1/3

1/3

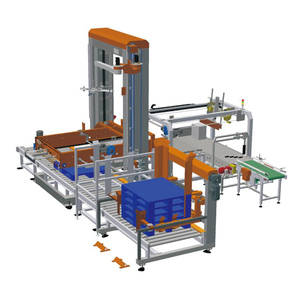

About universal robots palletizing

Where to Find Universal Robots Palletizing Suppliers?

China's industrial automation sector has emerged as a global hub for robotic palletizing solutions, with key manufacturing clusters in Shandong, Jiangxi, and Shanghai driving innovation and cost efficiency. Qingdao in Shandong Province hosts integrated packaging machinery ecosystems, enabling suppliers like Qingdao Ausense to leverage localized supply chains for conveyor systems, strapping units, and robotic integration—reducing component procurement lead times by up to 30%. Meanwhile, Jiangxi’s Nanchang region specializes in mid-payload industrial robots (20–35 kg), supported by state-backed smart manufacturing initiatives that lower production costs by 18–22% compared to European or North American counterparts.

These regional advantages are amplified by vertically aligned production networks, where casting, CNC machining, control system assembly, and final integration occur within compact geographic zones. This structure enables rapid prototyping (typically 7–14 days for customized palletizing cells) and scalable batch production. Buyers benefit from streamlined logistics, access to specialized engineering talent, and flexible MOQ policies—some suppliers offer single-unit orders for testing, while maintaining capacity for turnkey lines exceeding 50 units monthly.

How to Choose Universal Robots Palletizing Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm compatibility with universal robot arms (UR series, BORUNTE, ESTUN, etc.) and verify integration capabilities for end-of-arm tooling (EOAT), vision guidance, and conveyor synchronization. Demand CAD layout support and functional specifications including reach radius (≥1850 mm), payload capacity (12–35 kg standard range), and cycle time benchmarks. For safety-critical environments, ensure compliance with ISO 10218 (industrial robots) and ISO/TS 15066 (collaborative robotics).

Production & Customization Assessment

Evaluate supplier infrastructure based on the following criteria:

- In-house design and assembly facilities (minimum 3,000m² recommended for system integrators)

- Dedicated R&D teams capable of providing layout drawings, simulation files, and I/O wiring diagrams

- Customization scope covering gripper types, labeling systems, strapping modules, and material handling configurations

Cross-reference product listings with customization tags such as “payload,” “color,” “material,” and “label” to assess engineering flexibility.

Transaction Risk Mitigation

Prioritize suppliers with verifiable performance metrics: on-time delivery ≥98%, response time ≤4 hours, and reorder rates above 15%. Utilize secure payment mechanisms such as escrow services, especially when engaging newer suppliers without extensive export histories. Request pre-shipment inspection reports and, where feasible, conduct virtual factory audits via live video walkthroughs of testing bays and calibration stations.

What Are the Best Universal Robots Palletizing Suppliers?

| Company Name | Verified Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Sample Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Qingdao Ausense Packing Equipment Co., Ltd. | Custom Manufacturer | Packaging Line, Wrapping Machines, Palletizers | US $1,200,000+ | 100% | ≤2h | 20% | Size, material, color, label, CAD layout, dispenser, strapping | $3,500–9,500 |

| Jiangxi Longen Intelligent Equipment Co., Ltd. | Custom Manufacturer | 6-Axis Industrial Robots, 4-Axis Palletizing Arms | US $1,000,000+ | 100% | ≤2h | 18% | Material, size, logo, packaging, graphic, color | $3,500–8,800 |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Multispecialty Supplier | Cobots, UR16e Systems, KUKA Manipulators | US $50,000+ | 100% | ≤7h | 20% | Payload, gripper, size, material, label, graphic | $20,000–35,000 |

| Gongboshi Robot Technology Co., Ltd. | Multispecialty Supplier | UR12e Cobots, Handling & Stacking Systems | US $20,000+ | 100% | ≤4h | <15% | Color, material, size, weight, packaging, label | $15,000–28,800 |

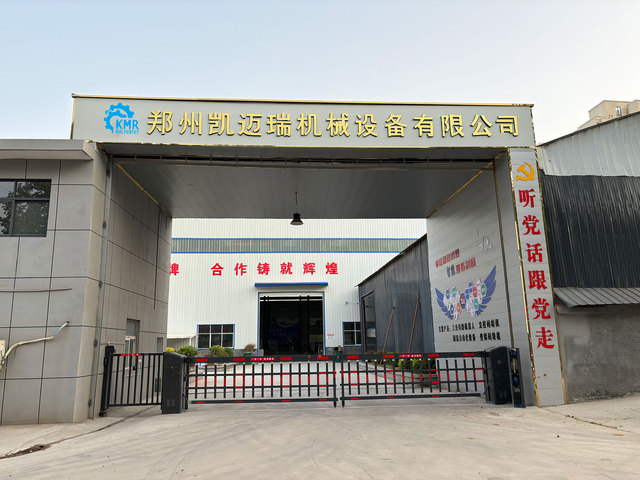

| Zhengzhou King Shine Auto Technology Co., Ltd. | Multispecialty Supplier | Articulated Robots, Laser & Welding Systems | US $60,000+ | 100% | ≤3h | <15% | Limited (focused on core robotic systems) | $14,440–40,000 |

Performance Analysis

Custom manufacturers dominate in scalability and after-sales reliability, with both Qingdao Ausense and Jiangxi Longen achieving 100% on-time delivery and reorder rates of 18–20%, indicating strong customer retention. These suppliers specialize in turnkey palletizing cells with full line integration capabilities. Multispecialty suppliers like Xiangjing (Shanghai) focus on high-payload cobots and UR-compatible systems, serving advanced automation markets but at significantly higher price points (averaging $25,000+ per unit). While all listed suppliers maintain perfect on-time delivery records, response times vary—Shanghai and Jiangxi-based firms average under 2 hours, offering faster technical engagement. Buyers seeking cost-effective entry-level systems should consider Jiangxi Longen’s 20kg payloads under $4,000, whereas those requiring precision cobot integration may prioritize Gongboshi or Xiangjing for UR12e/UR16e compatibility.

FAQs

How to verify universal robots palletizing supplier reliability?

Validate certifications through official registries and request documentation of quality management systems (ISO 9001 preferred). Analyze transaction history for consistent order fulfillment and review customization tags for evidence of engineering depth. Direct technical inquiries can assess responsiveness and domain expertise.

What is the typical lead time for palletizing robot systems?

Standard configurations ship within 15–25 days. Customized systems with conveyors, dispensers, or multi-arm coordination require 30–45 days, depending on complexity. Air freight adds 5–10 days globally; sea freight ranges from 20–40 days based on destination.

Can suppliers integrate universal robots into existing production lines?

Yes, most suppliers provide retrofitting services, including PLC interface programming, safety fencing design, and synchronization with upstream/downstream equipment. Technical documentation such as I/O schematics, Modbus/TCP protocols, and 3D layout models are typically included.

Do suppliers offer free samples or trial units?

Sample availability depends on order scale. Some manufacturers waive fees for pilot installations linked to future bulk purchases. Otherwise, expect sample costs to cover 40–60% of unit price, often credited toward subsequent orders.

What customization options are commonly available?

Suppliers routinely support adjustments to arm length, payload capacity, gripper type (vacuum, clamp, magnetic), conveyor width, pallet stack height, labeling systems, and software interfaces. Advanced options include RFID tracking, barcode reading, and dynamic path planning via machine vision.