Use Of Automation In A Manufacturing Industry

CN

CN

1/4

1/4

CN

CN

1/3

1/3

About use of automation in a manufacturing industry

Where to Find Automation Equipment Suppliers for Manufacturing Industries?

China remains the global epicenter for industrial automation equipment manufacturing, with concentrated supplier clusters in Guangdong and Henan provinces offering distinct competitive advantages. The Pearl River Delta region, particularly Shenzhen and Dongguan, hosts advanced automation engineering hubs specializing in smart production lines, robotics integration, and Industry 4.0-compliant systems. These areas benefit from mature electronics supply chains and a high density of R&D talent, enabling rapid prototyping and scalable deployment.

Meanwhile, Zhengzhou in Henan has emerged as a key center for packaging and assembly line automation, leveraging cost-efficient logistics networks and proximity to steel and mechanical component suppliers. This regional specialization allows buyers to access vertically integrated production ecosystems—spanning design, machining, control system programming, and final assembly—within compact geographic zones. Key benefits include reduced lead times (typically 30–60 days depending on complexity), 15–25% lower unit costs compared to Western manufacturers, and strong flexibility for both standard and custom-engineered solutions.

How to Choose Automation Equipment Suppliers for Manufacturing Applications?

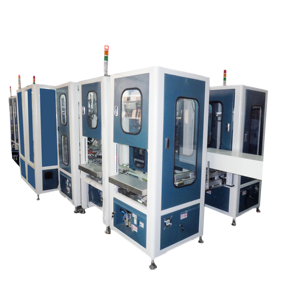

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Expertise & Product Range

Assess suppliers’ core competencies in specific automation domains such as robotic integration, conveyor systems, labeling machinery, or precision dispensing. Prioritize vendors demonstrating documented experience in your target industry segment (e.g., automotive, electronics, consumer goods). Verify compatibility with Industry 4.0 protocols like PLC control, SCADA integration, and IoT-enabled monitoring.

Production Capacity & Customization Capability

Evaluate infrastructure indicators including facility scale, in-house engineering teams, and CNC/assembly line availability. Suppliers capable of end-to-end customization—from concept design to commissioning—offer greater adaptability for complex workflows. Confirm minimum order quantities (MOQs), which typically range from 1 set for specialized systems to higher volumes for standardized units.

- Target suppliers with dedicated R&D resources and modular design platforms

- Verify support for OEM/ODM configurations and integration with existing factory layouts

- Cross-reference listed product ranges with actual build examples via video audits or site visits

Quality Assurance & Transaction Reliability

While formal certifications (ISO 9001, CE, RoHS) are not always explicitly stated in available data, performance metrics such as on-time delivery rates and response times serve as proxies for operational discipline. Favor suppliers reporting 100% on-time delivery and sub-6-hour average response times. Reorder rates above 20% indicate customer satisfaction and post-sale reliability.

Conduct due diligence through sample testing, especially for critical parameters like cycle time accuracy, repeatability tolerance, and mean time between failures (MTBF). Utilize secure payment mechanisms and require pre-shipment inspection clauses to mitigate risk.

What Are the Leading Automation Equipment Suppliers for Manufacturing Use?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Assembly Lines, Industrial Machinery, Packaging Machines | $5,000–70,000 | 1 set | 100% | ≤5h | 100% | US $2,000+ |

| Zhengzhou Weizhengyuan Automation Equipment Co., Ltd. | Labeling Machines, Filling & Capping Systems, Conveyors | $1,800–3,500 | 1 set | 100% | ≤1h | <15% | US $20,000+ |

| Hunan Junjiesheng Automation Equipment Co., Ltd. | Gluing Machines, Electronics Production Machinery | $770–30,000 | 1 set | 100% | ≤2h | - | - |

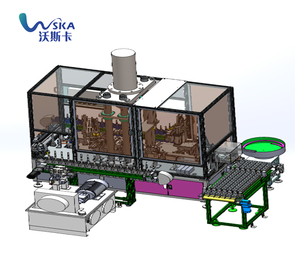

| Shenzhen Wska Electronics Co., Ltd. | Industrial Robots, Motor Assembly Lines, Machinery | $30,000–276,000 | 1 set | 100% | ≤6h | - | - |

| Shenzhen Jufeng Jingke Automation Technology Co., Ltd. | Linear Robots, XYZ Platforms, Robot Integration Components | $60–550 (per piece) | 1 piece | 100% | ≤1h | 22% | US $10,000+ |

Performance Analysis

Shenzhen-based suppliers dominate high-value automation systems, with Wska Electronics offering large-scale motor and industrial robot assembly lines exceeding $265,000 per unit—suitable for automotive and heavy manufacturing applications. In contrast, Hunan Junjiesheng provides entry-level automation at competitive pricing, including glue dispensing machines starting under $800, ideal for small electronics producers. Zhengzhou Weizhengyuan stands out for fast responsiveness (≤1h) and mid-range filling and labeling automation, though its low reorder rate suggests potential gaps in long-term service delivery. Shenzhen Jufeng Jingke specializes in modular components sold by the piece, enabling incremental automation upgrades. Buyers seeking full turnkey lines should prioritize suppliers with proven system integration experience and verifiable project references.

FAQs

How to verify automation equipment supplier credibility?

Validate technical claims through video demonstrations of running systems and request detailed schematics for control architecture. Analyze historical transaction data, focusing on consistent on-time delivery and repeat business. Request contactable client references, particularly those in similar production environments.

What is the typical lead time for automated manufacturing systems?

Standard configurations generally ship within 30–45 days after order confirmation. Customized or large-scale production lines may require 60–90 days, depending on engineering validation and component sourcing. Expedited builds can reduce timelines by 10–15% with premium fees.

Do suppliers support international voltage and safety standards?

Reputable vendors offer configurable electrical systems (e.g., 220V/380V, 50Hz/60Hz) and can integrate CE-compliant components upon request. Confirm adherence to destination-market regulations (such as UL, CSA, or IEC standards) during technical specification review.

Can buyers request pilot runs or functional prototypes?

Yes, many suppliers provide prototype development for customized systems, typically delivering proof-of-concept units within 4–6 weeks. Pilot run costs vary but often apply toward full production orders. Clarify software interface requirements (e.g., HMI language, communication protocols) early in development.

What are common MOQs and pricing structures?

Most suppliers list MOQs at 1 set for complete machines, while component-level automation (e.g., linear modules) may be available per piece. Pricing reflects system complexity: basic labeling or gluing units start below $2,000, whereas fully automated robotic assembly lines exceed $250,000. Bulk discounts and container-load incentives are negotiable based on volume commitments.