Vendor Performance Evaluation Process

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

About vendor performance evaluation process

Where to Source Vendor Performance Evaluation Process Services?

The global market for vendor performance evaluation services is increasingly concentrated among specialized quality assurance and compliance firms in Asia, particularly in China and Vietnam. These regions host a growing number of inspection, audit, and certification providers that support international procurement teams with standardized supplier assessment frameworks. Firms in Shanghai, Guangzhou, and Ho Chi Minh City benefit from proximity to major manufacturing hubs, enabling rapid deployment of on-site audits across electronics, industrial equipment, textiles, and automotive supply chains.

These service clusters offer integrated ecosystems combining digital reporting platforms, multilingual auditor networks, and accreditation partnerships with international standards bodies. This infrastructure allows for scalable operations—supporting everything from single-factory inspections to enterprise-wide supplier qualification programs. Buyers gain access to real-time audit data, photographic evidence logs, and AI-enhanced risk scoring models, reducing dependency on internal compliance teams. Lead times for standard evaluations typically range from 5–10 business days, with expedited services available within 72 hours in high-density industrial zones.

How to Evaluate Vendor Performance Evaluation Service Providers?

Selecting a reliable provider requires structured due diligence focused on technical competence, operational responsiveness, and methodological transparency.

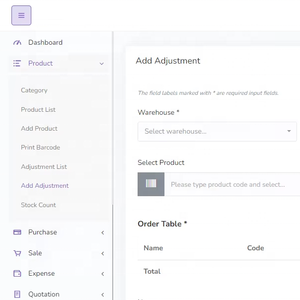

Methodological Rigor & Certification Alignment

Confirm the supplier employs internationally recognized audit protocols such as ISO 19011 (guidelines for management system auditing) or ANSI/ASQ Z1.4 (sampling procedures). Look for integration with widely accepted performance metrics: On-Time Delivery (OTD), Quality Defect Rate (QDR), Corrective Action Response Time (CART), and Reorder Rate as indicators of historical reliability. While formal certifications like ISO 17020 (for inspection bodies) are not universally held, their presence signals adherence to impartiality and technical consistency standards.

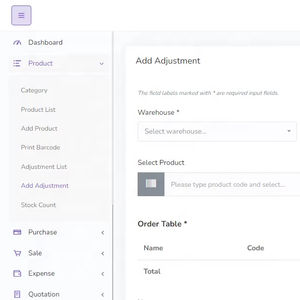

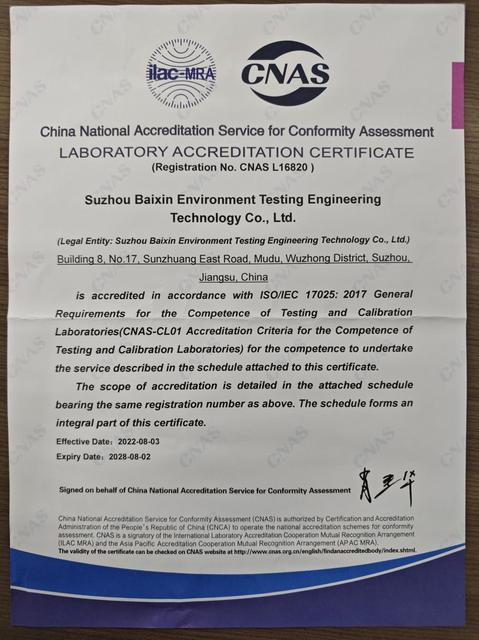

Service Scope and Technical Capabilities

Assess the breadth and depth of offered services:

- Pre-assessment questionnaires and risk-based scoring models

- On-site factory audits covering production capacity, quality control systems, labor practices, and environmental compliance

- Product-specific inspection protocols (e.g., pre-shipment, during production, container loading supervision)

- Digital reporting with time-stamped photos, GPS verification, and PDF/Excel deliverables

Prioritize suppliers offering customizable checklists aligned with your industry’s regulatory requirements (e.g., AQL standards for consumer goods).

Operational Responsiveness and Transaction Security

Analyze response time benchmarks—sub-12-hour initial replies indicate dedicated client support structures. Use verifiable delivery records; a 100% on-time report delivery rate suggests strong internal workflow management. For transaction protection, prefer providers who support milestone-based payment terms or escrow-compatible invoicing, especially when engaging for high-value audit programs.

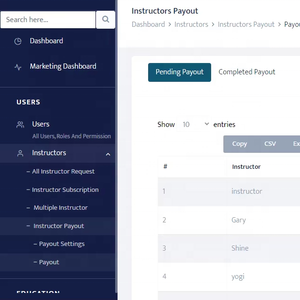

What Are the Leading Vendor Performance Evaluation Process Providers?

| Company Name | Core Services | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Specializations |

|---|---|---|---|---|---|---|

| Applus China Co., Ltd. | Supplier Evaluation, Third-Party Inspection, Quality Control | $1–5 | 1 unit | 100% | ≤7h | Industrial equipment, steel structures, wellhead assemblies |

| INTER Q & A SERVICES, UNIPESSOAL LDA | Factory Audit, Supplier Manufacturing Evaluation, Pre-Shipment Inspection | $250 | 1 unit | - | ≤2h | Quality control, product certification, loading supervision |

| BX Certification & Inspection Ltd. | Pre-Shipment Evaluation, Factory Inspection, Product Testing | $50–500 | 1 piece | 100% | ≤11h | China-based supplier audits, QC for export-ready goods |

| MEKONG DELTA IMPORT EXPORT COMPANY LIMITED | Manufacturer Assessment, Comprehensive Quality Control Audits | $0.10–$3 | 5,000 pcs | - | ≤23h | Bamboo crafts, textiles, garden products, apparel |

| Shanghai Wesure Information Technology Co., Ltd. | Predictive Logistics Analytics, AI-Driven Supply Chain Risk Scoring | $500 | 1 unit | 100% | - | Data analytics, supplier risk forecasting, logistics optimization |

Performance Analysis

Applus China and BX Certification demonstrate high operational reliability with verified 100% on-time delivery rates and competitive response times, making them suitable for time-sensitive audit cycles. INTER Q & A SERVICES stands out for exceptional responsiveness (≤2h), ideal for buyers requiring rapid scheduling and urgent reporting. Shanghai Wesure represents a technology-forward approach, offering predictive analytics rather than physical audits—suited for enterprises seeking proactive supplier risk modeling. MEKONG DELTA offers cost-efficient solutions for bulk audit packages but targets niche consumer goods sectors. Pricing varies significantly: low-cost options ($1–5) often cover limited-scope assessments, while $250+ services include comprehensive plant walkthroughs and detailed compliance documentation.

FAQs

How to verify the credibility of a vendor evaluation service provider?

Cross-check claimed methodologies against recognized auditing standards. Request sample audit reports to assess depth of analysis, photo documentation, and structural completeness. Validate company credentials through business registries and review client references where available.

What is the typical lead time for a supplier factory audit?

Standard audit scheduling takes 5–7 business days from engagement. Expedited services in major Chinese industrial zones can be completed within 72 hours. Report delivery typically follows within 24–48 hours post-inspection.

Can these services be customized for specific industries?

Yes, leading providers tailor audit checklists for sectors including medical devices, automotive components, food packaging, and renewable energy systems. Customization includes regulatory benchmarking (e.g., FDA, IATF 16949) and process-specific KPIs.

Do providers offer recurring evaluation programs?

Many suppliers support ongoing monitoring arrangements, including quarterly audits, annual requalification reviews, and continuous performance dashboards. These are particularly valuable for managing large supplier portfolios.

Are digital audit platforms included in the service?

Most modern providers deliver reports via secure online portals with searchable archives, exportable data formats, and multi-user access. Some integrate with ERP or procurement systems for automated supplier scorecard updates.