Supplier Performance Evaluation Process

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

About supplier performance evaluation process

Where to Find Supplier Performance Evaluation Process Providers?

China has emerged as a central hub for third-party supplier performance evaluation services, with key providers concentrated in industrial and technology centers such as Zhejiang, Fujian, Guangdong, and Jiangsu provinces. These regions host specialized testing, inspection, and certification (TIC) firms that support global supply chains across electronics, manufacturing, construction materials, and consumer goods sectors. Zhejiang and Fujian are home to accredited laboratories offering ISO/IEC 17025-compliant assessments, while Guangdong’s proximity to Shenzhen’s innovation ecosystem enables rapid deployment of digital feedback systems for real-time supplier scoring.

The clustering of technical expertise and logistics infrastructure allows providers to deliver scalable audit solutions with standardized reporting frameworks. Many suppliers operate within integrated service ecosystems, combining on-site factory audits, product compliance testing, and data analytics platforms. This integration reduces evaluation lead times to 5–15 business days for standard inspections, with expedited digital reporting available within 72 hours. Cost efficiencies range from 30–60% compared to Western-based consultants, driven by lower labor costs and streamlined regulatory processes.

How to Choose Supplier Performance Evaluation Process Providers?

Selecting a reliable provider requires due diligence across three core areas:

Compliance & Certification Standards

Verify adherence to internationally recognized benchmarks such as ISO 9001 (quality management), ISO/IEC 17025 (laboratory competence), and industry-specific certifications including CE, UL, RoHS, and PSE. For suppliers handling export-oriented audits, confirm experience with VDA 6.3 (automotive process audits) or SA8000 (social accountability). Documentation of test methodologies and accreditation bodies should be readily accessible.

Service Scope and Technical Capabilities

Assess the breadth of evaluation offerings:

- On-site factory audits covering quality control systems, production capacity, and environmental compliance

- Product-specific performance testing (e.g., structural integrity, electrical safety, material durability)

- Digital feedback systems for customer satisfaction and service rating collection

- Custom reporting formats aligned with buyer-specific KPIs

Prioritize providers with multispecialty capabilities and in-house laboratories to ensure consistency and reduce outsourcing dependencies.

Operational Reliability Metrics

Analyze performance indicators such as on-time delivery rate (target: ≥95%), average response time (ideal: ≤3 hours), and reorder rate as proxies for client satisfaction. High-performing suppliers maintain transparent communication channels and offer post-evaluation consultation. Transaction security is enhanced through structured pricing models and clear minimum order requirements (MOQ), typically starting at one unit or set for digital terminals and one piece for audit services.

What Are the Best Supplier Performance Evaluation Process Providers?

| Company Name | Location | Core Services | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Gangxin Testing Technology Co., Ltd. | Zhejiang, CN | Structural seismic inspection, lab testing & certification | $28.66–428.66 | 1 dozen | 100% | ≤3h | - | |

| Guangzhou Ideal Running Technology Co., Ltd. | Guangdong, CN | Customer feedback terminals, Android-based satisfaction systems | $128–399 | 1 unit | 75% | ≤2h | <15% | |

| Fujian Bodun Inspection Service Co., Ltd. | Fujian, CN | CE, FCC, UL, PSE, LFGb certifications, EMC testing | $50–300 | 1 set | 100% | ≤3h | - | Trusted service provider |

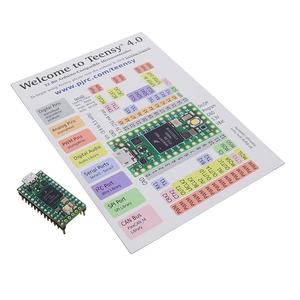

| Jiangsu Chengxin Inspection Testing And Certification Co., Ltd. | Jiangsu, CN | Metal failure analysis, welding performance testing | $50–25,000 | 1 piece | 100% | ≤7h | - | Multispecialty Supplier |

| Shenzhen Wtlplus Green Supplier Chain Management Co., Ltd. | Shenzhen, CN | VDA 6.3 process audits, third-party quality control, market research | $0.80–258 | 1–100 pieces | 100% | ≤2h | <15% |

Performance Analysis

Providers like Zhejiang Gangxin and Fujian Bodun demonstrate strong reliability with 100% on-time delivery and prompt response times, making them suitable for time-sensitive compliance evaluations. Jiangsu Chengxin specializes in high-value industrial testing, including metal welding and failure analysis, though its higher price points reflect technical complexity. Shenzhen Wtlplus offers cost-effective audit packages starting below $1 per unit for bulk orders, ideal for large-scale supplier screening programs. Guangzhou Ideal Running focuses on digital service evaluation tools but shows a lower reorder rate, suggesting potential gaps in long-term client retention. Buyers requiring end-to-end traceability should prioritize verified suppliers with documented quality control processes and multi-standard certification experience.

FAQs

How to verify a supplier performance evaluation provider’s credibility?

Request copies of accreditation certificates (e.g., CNAS, CMA) and validate them against issuing authority databases. Review sample audit reports to assess depth of analysis, clarity of findings, and alignment with international standards. Confirm whether field auditors are certified professionals with sector-specific experience.

What is the typical lead time for a supplier audit report?

Standard on-site audits take 7–10 business days from scheduling to final report delivery. Expedited digital evaluations using remote documentation review can be completed in 3–5 days. Complex technical assessments (e.g., metallurgical testing) may require up to 20 days depending on laboratory workload.

Can these providers customize evaluation criteria?

Yes, most established firms allow customization of audit checklists, scoring matrices, and reporting formats. Clients can integrate proprietary KPIs, ethical sourcing requirements, or environmental compliance metrics. Customization options are often included in premium service tiers.

Are samples required for performance evaluation services?

For product testing components, physical samples are mandatory. For factory audits or digital system deployments, no physical sampling is needed—providers rely on document reviews,现场 inspections, and system configuration. Sample testing fees vary based on complexity and volume.

Do providers offer ongoing supplier monitoring programs?

Some suppliers, particularly those offering digital feedback terminals or SaaS-based audit platforms, provide subscription models for continuous performance tracking. These include quarterly re-audits, automated dashboards, and alert systems for non-conformance detection.