Supplier Performance Management Process

CN

CN

1/19

1/19

1/1

1/1

CN

CN

1/2

1/2

1/36

1/36

About supplier performance management process

Where to Find Supplier Performance Management Process Solutions?

Global supply chains increasingly rely on digital performance management systems to monitor supplier compliance, delivery accuracy, and operational efficiency. A significant portion of these technology solutions originate from specialized software and electronics manufacturers in China, particularly within the Guangdong and Shandong regions. These hubs host vertically integrated ecosystems combining hardware development, embedded software engineering, and cloud-based analytics platforms.

Manufacturers in Shenzhen and Guangzhou dominate the production of intelligent monitoring modules and IoT-enabled tracking devices, often integrating power management ICs and digital signage with backend performance analytics. Meanwhile, software-centric developers in Jinan and Zhengzhou focus on lead management, learning management systems (LMS), and business intelligence applications tailored for supplier evaluation. This geographic specialization enables buyers to source both standalone software platforms and hybrid hardware-software systems optimized for real-time supplier performance tracking.

How to Choose Supplier Performance Management Process Providers?

Selecting an effective provider requires rigorous evaluation across technical, operational, and transactional dimensions:

System Functionality & Integration

Ensure the solution supports key performance indicators (KPIs) such as on-time delivery rate, reorder frequency, response time benchmarks, and quality defect tracking. Verify compatibility with existing ERP or procurement systems through API availability. Cloud-based LMS or digital signage platforms should support remote data updates and multi-location dashboards for centralized supplier oversight.

Production and Development Capability

Assess technical infrastructure based on the following criteria:

- Proven expertise in software development frameworks or electronic control systems

- In-house R&D teams capable of customizing reporting interfaces and alert mechanisms

- Use of standardized components (e.g., PMICs, PCBs) with documented lifecycle management

Cross-reference product listings with response times and delivery performance to validate operational responsiveness.

Transaction Reliability & Quality Assurance

Prioritize suppliers demonstrating consistent on-time delivery (≥97%) and sub-4-hour average response times. Review available tags indicating online revenue volume and reorder rates as proxies for customer satisfaction. For hardware-integrated systems, request test reports verifying component durability and power efficiency under continuous operation.

What Are the Leading Supplier Performance Management Process Providers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (Min Order) | Core Applications |

|---|---|---|---|---|---|---|

| HINDUSTANSOFT CORPORATION | Software | Data not available | ≤1h | Data not available | $500–$1,800; 1 unit | LMS, Lead & Business Management Software |

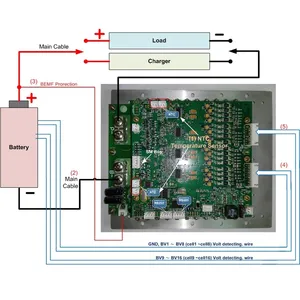

| INTELLISENSE TECHNOLOGY | PCB & PCBA, Alarm Systems | Data not available | ≤4h | Data not available | $99–$499; 99 pieces | Performance-Optimized Electronic Systems |

| Guangzhou Veeluame Technology Co., Ltd. | Digital Signage, LCD Displays | 100% | ≤2h | Data not available | $2,368–$4,699; 1 unit | Scalable Advertising & Monitoring Displays |

| Shenzhen MINCONDA Technology Co., Ltd. | Power Management ICs, AC/DC Converters | 100% | ≤1h | <15% | $0.10–$1.00; 1 piece | Embedded Performance Monitoring Circuits |

| Shenzhen VictoryStar Technology.,Limited | Electronic Modules, Power Boards | 100% | ≤1h | <15% | $1.85–$2.31; 10 pieces | High-Efficiency DC-DC Power Management |

Performance Analysis

Hardware-focused suppliers like Shenzhen MINCONDA and Shenzhen VictoryStar offer high reliability (100% on-time delivery) and rapid communication, making them suitable for integration into automated supplier monitoring networks. Their low-cost, scalable IC and module designs enable deployment across large-scale procurement environments. In contrast, software providers such as HINDUSTANSOFT CORPORATION emphasize fast response cycles (≤1h) and flexible licensing models ideal for dynamic supplier evaluation workflows.

Guangzhou Veeluame stands out for delivering high-value digital display systems with full delivery assurance, enabling visual supplier scorecard implementations. While reorder rates are limited across most suppliers, consistent on-time performance and short response windows indicate strong service discipline—critical for maintaining continuous supplier assessment processes.

FAQs

How to verify a supplier performance management system's reliability?

Evaluate documented delivery performance and response metrics. Request demonstration units or software trials to assess interface usability and data accuracy. Confirm component sourcing transparency, especially for embedded electronics used in industrial monitoring setups.

What is the typical lead time for performance management solutions?

Software-based systems can be deployed within 1–2 weeks post-purchase. Hardware-integrated displays or control modules typically require 20–30 days for production and testing. Custom configurations may extend timelines by 10–15 days depending on complexity.

Can these systems be customized for specific KPIs?

Yes, most software platforms and programmable hardware displays support configurable dashboards. Buyers should provide detailed requirements for metrics such as delivery deviation, quality rejection rates, or communication latency to ensure proper system calibration.

Do suppliers offer sample units or trial versions?

Many providers offer demo software or single-unit purchases at listed prices. For hardware modules, samples are typically available at minimum order quantities, with costs recoverable upon placement of bulk orders.

Are there export compliance considerations?

Ensure electronic components comply with destination-country regulations regarding electromagnetic compatibility (EMC) and environmental standards (RoHS, REACH). Software exports should adhere to local data privacy laws when handling supplier performance records.