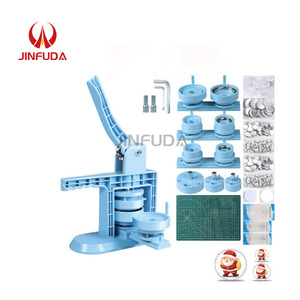

Vevor Button Maker

About vevor button maker

Where to Find VEVOR Button Maker Suppliers?

China's industrial hubs in Jiangsu, Henan, and Guangdong provinces serve as primary manufacturing centers for button making machinery, including models comparable to the VEVOR brand. Yancheng in Jiangsu Province hosts a concentrated cluster of specialized machinery producers focusing on manual and semi-automatic button press systems, with established supply chains for dies, molds, and metal components. This regional specialization enables streamlined production of 25–75mm diameter badge-making equipment used in promotional, apparel, and DIY sectors.

Suppliers leverage vertically integrated operations that encompass CNC machining, tooling fabrication, and final assembly within compact geographic zones—reducing component procurement time by up to 40%. Buyers benefit from agile production cycles, with standard machine orders typically fulfilled within 15–25 days. Localized sourcing of raw materials such as ductile iron, aluminum alloys, and spring steel contributes to 18–25% cost efficiency compared to equivalent Western-built machines. Export infrastructure in Shanghai, Ningbo, and Qingdao supports global distribution, with FOB terms commonly available for single-unit and containerized shipments.

How to Choose VEVOR Button Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Confirm compatibility with standard button sizes (25mm, 38mm, 58mm, 75mm) and material thickness tolerances. While formal certifications like ISO 9001 or CE are not universally declared in this segment, prioritize suppliers providing documented quality control procedures, especially for load testing and die alignment precision. Machines intended for commercial use should demonstrate structural integrity under repeated compression cycles (minimum 10,000-cycle endurance).

Production Capacity Assessment

Evaluate supplier capability through key indicators:

- Minimum factory area exceeding 1,000m² for stable output

- In-house tooling and die design capabilities

- Demonstrated product range focused on button-making or related pressing applications

Cross-reference online listing volume with reorder rates and response times to assess operational maturity. Suppliers with dedicated R&D teams can better accommodate custom die configurations or ergonomic modifications.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with delivery and performance verification. Request sample units to evaluate build quality, ease of operation, and consistency in button crimping. Analyze after-sales support responsiveness, particularly for spare parts availability and technical troubleshooting. Prioritize suppliers with ≤7-hour average response times and ≥90% on-time delivery records.

What Are the Best VEVOR Button Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Jiangsu, CN | Button Making Machines (944) | US $130,000+ | 100% | ≤3h | 17% | $60–620 | 1 set |

| Foshan Zeming Hardware Technology Co., Ltd. | Guangdong, CN | Buttons (400) | US $20,000+ | 100% | ≤3h | 28% | $18–150 | 1–5 sets |

| Henan Growing Mechanical Equipment Co., Ltd. | Henan, CN | Seeders & Transplanters (265) | US $8,000+ | 100% | ≤7h | 66% | $185–2,468 | 1 set |

| Golden Gateway Trading Inc | Unspecified | Garden Sets (1732) | US $30,000+ | 90% | ≤3h | - | $54.60–98.21 | 1 piece |

| Taizhou My Button Machine Co., Limited. | Zhejiang, CN | Button Making Machines (125) | US $40,000+ | 78% | ≤10h | <15% | $28–3,950 | 1 box/piece |

Performance Analysis

Yancheng Stik Pro stands out with the highest product specialization and revenue volume, offering broad model variety at competitive pricing. Its 100% on-time delivery and rapid response time indicate robust order management systems. Foshan Zeming targets budget-conscious buyers with entry-level manual presses starting at $18, supported by a strong reorder rate reflective of component reliability. Henan Growing, despite lower online visibility, achieves the highest customer retention (66% reorder rate), suggesting effective post-sale engagement. Golden Gateway provides low MOQ access ideal for sampling or small businesses, though its mixed product portfolio may limit technical depth. Taizhou My Button Machine offers high-end electric and automatic models but exhibits weaker fulfillment metrics, indicating potential scalability constraints.

FAQs

How to verify button maker supplier reliability?

Validate operational legitimacy through business registration documents and transaction history. Request references or third-party inspection reports if available. Assess product consistency by ordering samples and evaluating mechanical alignment, handle ergonomics, and crimp quality across multiple test runs.

What is the typical lead time for button maker machines?

Standard manual models ship within 7–15 days after order confirmation. Customized or automated systems may require 20–35 days depending on complexity. Air freight delivers samples in 5–10 days globally; sea freight takes 25–40 days for full container loads.

Can suppliers customize button makers for specific sizes or automation levels?

Yes, many manufacturers offer OEM/ODM services for die customization (e.g., oval or rectangular shapes), dual-station setups, or servo-driven automation. Technical drawings or physical prototypes are typically required to initiate development, with engineering feedback provided within 3–5 business days.

Do suppliers provide spare parts and technical support?

Most suppliers include basic spare components (pins, springs, dies) with initial orders. Long-term support varies—prioritize those listing spare parts catalogs or offering video-based troubleshooting. High-reorder-rate suppliers generally maintain better inventory continuity for wear-prone elements.

What are common payment and shipping terms?

Payment options include T/T, L/C, and platform-managed escrow. Shipping is typically offered on FOB terms; CIF arrangements are negotiable for bulk orders. Sample units usually ship via express carriers (DHL, FedEx); mass orders move via air or sea freight based on volume and urgency.