Custom Button Maker

Top sponsor listing

Top sponsor listing

About custom button maker

Where to Find Custom Button Maker Suppliers?

China remains the dominant hub for custom button manufacturing, with key production clusters in Guangdong, Fujian, and Zhejiang provinces. These regions host vertically integrated supply chains specializing in metal stamping, die-casting, resin molding, and fabric covering techniques essential for diverse button types. Shenzhen and Guangzhou serve as primary export centers, offering streamlined logistics and proximity to material suppliers for brass, zinc alloy, ABS, and polyester—reducing lead times by 15–25% compared to non-specialized regions.

The industrial ecosystem supports high-volume output and rapid prototyping, with many facilities equipped for OEM/ODM services including logo engraving, color matching, and custom packaging. Buyers benefit from concentrated expertise in fashion, apparel, and accessory manufacturing, enabling seamless integration of buttons into broader garment production cycles. Typical advantages include MOQs as low as 100 pieces, per-unit costs under $0.10 at scale, and customization flexibility across size, material, and design parameters.

How to Choose a Custom Button Maker Supplier?

Evaluate potential partners using the following criteria to ensure quality, reliability, and compliance:

Production & Customization Capabilities

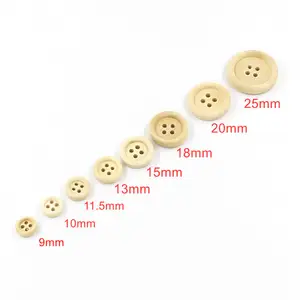

Confirm access to core processing technologies: CNC stamping for metal buttons, injection molding for plastic variants, and ultrasonic welding for composite designs. Suppliers should support Pantone color matching, multi-layer plating (e.g., nickel, brass, antique finishes), and laser/logo embossing. Prioritize vendors listing 200+ product variations, indicating established tooling and mold libraries that reduce setup time for new designs.

Quality Assurance Protocols

While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates ≥97% and reorder rates >25% serve as operational proxies for process stability. Verify that suppliers conduct in-line inspections for dimensional accuracy, coating adhesion, and structural integrity. For EU and North American markets, ensure compliance with REACH and RoHS regulations regarding heavy metals and restricted substances in apparel accessories.

Transaction Reliability Indicators

Assess responsiveness (target ≤2 hours) and order fulfillment history. A reorder rate exceeding 25% suggests customer satisfaction with product consistency and service. Cross-reference online revenue indicators (e.g., US $30,000+ annual digital sales) as evidence of sustained commercial activity. Request sample batches to validate material claims and workmanship before committing to bulk orders.

What Are the Top Custom Button Maker Suppliers?

| Company Name | Main Materials | Customization Options | MOQ Range | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

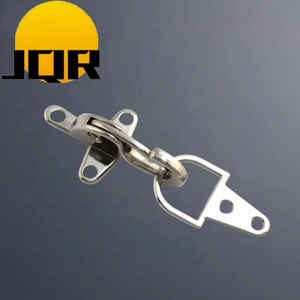

| Shishi Jinqiuri Metal Products Co., Ltd. | Metal, Zinc Alloy, Brass | Color, Size, Logo, Packaging, Graphic | 300–1000 pcs | $0.25–0.38 | 97% | ≤2h | 28% | US $30,000+ |

| Guangzhou Shuangchen Apparel Co., Ltd. | Steel, Zinc Alloy, Metal | Color, Design, Logo, Material, Size, Style | 100–500 pcs | $0.10–0.35 | 100% | ≤2h | <15% | US $90,000+ |

| Wyse Industrial (Shenzhen) Co., Ltd. | Brass, Metal, Fabric-Covered | Size, Logo, Color, Magnet Type | 100–1000 pcs | $0.03–0.09 | 97% | ≤3h | 15% | US $30,000+ |

| GUANG ZHOU AUXWORLD TRADE CO.,LTD. | Metal, Resin, Crystal-Embedded | Color, Material, Logo, Graphic, Label | 100–500 sets | $0.05–0.20 | 100% | ≤2h | 31% | US $10,000+ |

| Zhejiang Soukou Information Technology Co., Ltd. | Resin, Polyester, ABS, Plastic | Color, Design, Logo, Shape | 2–1000 sets | $0.04–0.09 | 100% | ≤12h | <15% | US $10,000+ |

Performance Analysis

Guangzhou Shuangchen Apparel leads in transaction volume (US $90,000+) and offers competitive pricing from $0.10/unit with low MOQs, though its sub-15% reorder rate may indicate room for service improvement. GUANG ZHOU AUXWORLD stands out with a 31% reorder rate and full on-time delivery record, reflecting strong buyer retention despite lower revenue volume. Zhejiang Soukou provides the most accessible entry point with MOQs starting at 2 pieces, ideal for sampling or micro-batches, but slower response times suggest limited staffing capacity. Shishi Jinqiuri and Wyse Industrial offer balanced performance with mid-tier pricing and proven reliability, suitable for medium-volume apparel producers.

FAQs

What materials are commonly used by custom button makers?

Primary materials include zinc alloy and brass for metal buttons, ABS and resin for plastic variants, and fabric-covered composites for soft-touch applications. Magnetic closures typically use iron-nickel plating with rubber seals. Suppliers often provide material certifications upon request.

What is the typical lead time for custom button production?

Standard orders take 10–20 days after sample approval. Rush production (7–10 days) is available from select suppliers for urgent needs. Add 5–10 days for international air shipping or 25–40 days for sea freight depending on destination.

Do suppliers offer free samples?

Most suppliers provide physical samples for validation. Fees may apply depending on complexity, though some waive costs for confirmed purchase intentions. Expect 3–7 days for sample preparation and additional shipping time.

Can I customize logos and packaging?

Yes, all listed suppliers support logo engraving, embossing, or printing. Custom packaging options include branded polybags, paper cards, and retail-ready boxes. Minimum quantities may apply for branded packaging runs.

How do I verify product compliance for export?

Request documentation confirming compliance with REACH, RoHS, or CPSIA standards where applicable. Conduct third-party lab testing if required by your market, particularly for children’s apparel or regulated textiles.