Buttons For Button Maker

1/29

1/29

1/2

1/2

1/27

1/27

1/5

1/5

1/29

1/29

1/1

1/1

1/1

1/1

1/17

1/17

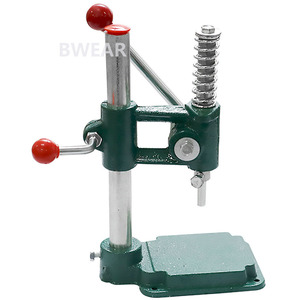

About buttons for button maker

Where to Find Suppliers for Buttons for Button Maker?

China remains the central hub for manufacturing buttons and related accessories, with key production clusters in Zhejiang, Guangdong, and Fujian provinces. These regions host vertically integrated supply chains that support both high-volume production and custom fabrication of components used in button-making machines. Wenzhou, known as the "Capital of China's Garment Accessories," specializes in precision-molded plastic, resin, and metal buttons compatible with automated and manual button makers. Foshan and Huizhou in Guangdong focus on hardware integration, producing durable tooling components and machine-ready blanks.

The industrial ecosystems in these zones enable efficient coordination between material suppliers, mold manufacturers, stamping facilities, and assembly lines—reducing lead times by up to 30% compared to fragmented sourcing models. Suppliers benefit from localized access to raw materials such as polyester resin, mother-of-pearl, wood, and zinc alloy, allowing cost reductions of 15–25% on finished units. Average production cycles range from 15–30 days for standard orders, with expedited fulfillment options available through pre-stocked inventory programs.

How to Choose Suppliers for Buttons for Button Maker?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Material & Technical Compatibility

Verify that supplied buttons are dimensionally consistent with standard button maker specifications (e.g., shank diameter, cap depth, back plate thickness). Resin, fabric-covered, and wooden variants must meet tolerance levels within ±0.1mm to ensure seamless machine processing. Request material data sheets confirming durability under compression forces typical in pressing operations (≥5 kN).

Quality Assurance Protocols

Prioritize suppliers demonstrating adherence to international quality benchmarks. While formal ISO 9001 certification is not universally present, consistent on-time delivery rates above 96% and reorder rates exceeding 20% indicate stable internal processes. Look for documented QC checkpoints including visual inspection, dimensional sampling, and batch traceability systems.

Production Scalability and Customization

Assess capacity based on minimum order quantity (MOQ) flexibility and output volume:

- Mass production: MOQs typically start at 1,000–5,000 pieces for standard designs

- Custom logo/button design: Supported down to 300-piece batches by select suppliers

- Daily output capacity ranges from 50,000 to 200,000 units depending on complexity

- In-house tooling capabilities allow rapid mold development (7–14 days) for bespoke shapes

Transaction Risk Mitigation

Utilize secure payment terms tied to performance milestones. Confirm response time metrics (ideally ≤5 hours) and evaluate communication responsiveness during initial inquiry stages. Favor suppliers with transparent online revenue histories and verifiable export experience to North America, Europe, or Southeast Asia. Conduct sample testing for colorfastness, structural integrity, and compatibility with common button press mechanisms before scaling orders.

What Are the Top Suppliers for Buttons for Button Maker?

| Company Name | Main Products | Price Range (Unit/MOQ) | On-Time Delivery | Reorder Rate | Avg. Response Time | Online Revenue |

|---|---|---|---|---|---|---|

| Foshan Zeming Hardware Technology Co., Ltd. | Button Making Machines, Fabric Cover Machines | $30–300/set; Min. 2–10 sets | 100% | 26% | ≤3h | US $20,000+ |

| Linhai Tianyang Machinery Manufacturing Co., Ltd. | Fully Automatic Button Making Machines | $7,000–11,000/set; Min. 1 set | 100% | <15% | ≤1h | US $1,000+ |

| Wenzhou Wiko Garments Accessories Co., Ltd. | Resin, Wood, Mother-of-Pearl Buttons | $0.01–0.06/piece; Min. 1,000–5,000 pcs | 100% | 17% | ≤5h | US $10,000+ |

| Wenzhou Banwei Garment Accessory Co., Ltd. | DIY Button Kits, Fabric-Cover Tools | $0.26–1.00/bag or set; Min. 2–10 units | 100% | 22% | ≤8h | US $20,000+ |

| Huizhou Yubo Garment Accessories Co., Ltd. | Custom Logo Buttons, Eco-Friendly Blanks | $0.01–0.12/piece; Min. 300–12,000 pcs | 96% | 27% | ≤3h | US $30,000+ |

Performance Analysis

Huizhou Yubo leads in customization agility and buyer retention, reflected in its 27% reorder rate and low per-unit pricing for bulk orders. Foshan Zeming and Wenzhou Banwei offer mid-tier equipment solutions ideal for small workshops requiring affordable entry-level button makers. Linhai Tianyang targets industrial-scale operators with fully automatic machinery priced above $7,000, though lower reorder frequency suggests niche adoption. Wenzhou-based Wiko provides diverse material options suitable for fashion and eco-conscious brands, maintaining competitive pricing without compromising delivery reliability.

FAQs

How to verify compatibility between buttons and button makers?

Confirm dimensional alignment with your machine’s die specifications—especially cap size (commonly 12–25mm), stem length, and backing disc diameter. Request physical or digital samples to test feed mechanism integration and pressing consistency prior to bulk procurement.

What is the typical lead time for button production?

Standard orders ship within 15–25 days after confirmation. Custom designs involving new molds or printed graphics may require an additional 7–14 days. Express production (7–10 days) is available from select suppliers at a premium.

Can suppliers provide free samples?

Most suppliers offer free samples for qualified buyers, particularly when followed by a purchase commitment. Shipping costs are typically borne by the buyer. Sample turnaround averages 3–7 days for stock items.

Are eco-friendly or sustainable buttons available?

Yes. Several suppliers produce biodegradable buttons using natural materials like coconut shell, bamboo, and recycled resin. Certifications such as OEKO-TEX or RoHS compliance can be requested for chemical safety assurance.

Do suppliers support OEM/ODM services?

Extensive OEM capabilities are standard among top-tier suppliers. Clients can submit logos, packaging designs, or unique shapes for replication. Digital proofing and prototype submission usually occur within 5–7 business days post-design approval.