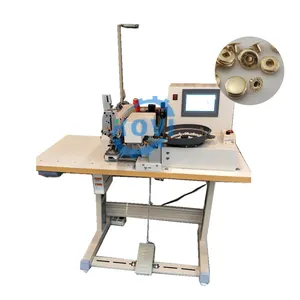

Button Maker How To

1/6

1/6

1/12

1/12

1/29

1/29

1/15

1/15

1/10

1/10

1/21

1/21

1/20

1/20

1/9

1/9

1/13

1/13

1/12

1/12

1/8

1/8

1/13

1/13

1/12

1/12

1/15

1/15

1/33

1/33

1/16

1/16

1/27

1/27

About button maker how to

Where to Find Button Maker Machine Suppliers?

China remains the central hub for button maker machine manufacturing, with key production clusters in Guangdong, Henan, and Tianjin offering distinct advantages in cost efficiency, customization, and supply chain integration. Dongguan and Guangzhou in Guangdong province host specialized machinery exporters focused on compact manual and semi-automatic systems ideal for small-to-mid volume producers. These regions benefit from proximity to plastic and metal component suppliers, reducing material lead times by 20–30% compared to offshore alternatives.

Henan and Tianjin serve as centers for engineered pressing equipment, integrating CNC fabrication and precision die-cutting technologies. Suppliers in these areas often operate vertically integrated workshops capable of producing full machine assemblies in-house, enabling tighter quality control and faster prototyping. The regional ecosystem supports rapid sourcing of stamping dies, magnetic backings, and polymer shells—critical components in badge and fridge magnet production. Buyers gain access to scalable solutions with MOQs as low as one set and lead times averaging 15–25 days for standard configurations.

How to Choose Button Maker Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compatibility

Verify machine compatibility with target button diameters (commonly 25mm to 75mm) and types—round, square, or custom shapes. Confirm support for multiple closure mechanisms: pin-back, magnet, snap, or adhesive. Machines should accommodate substrates including paper, polyester film, and thin metal sheets. For high-volume operations, assess force tonnage (typically 1–5 tons) and cycle speed consistency.

Production Capability Verification

Evaluate supplier infrastructure through available metrics:

- Facility size and production line automation level

- In-house tooling capacity for mold/die development

- Monthly output capability (ranging from 200–1,000 units per mid-tier supplier)

- Customization depth: color, logo imprinting, packaging, and labeling options

Cross-reference response time (≤2 hours preferred) and on-time delivery rates (>94%) as indicators of operational reliability.

Quality Assurance & Transaction Security

Prioritize suppliers demonstrating compliance with international quality expectations. While formal ISO 9001 certification is not universally present, consistent on-time delivery (≥97%) and low reorder rates (<15%) suggest stable processes. Use secure payment methods such as escrow services and request sample testing before bulk orders. Assess build quality through material thickness, frame rigidity, and alignment precision during compression cycles.

What Are the Best Button Maker Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Talent (Tianjin) Electronics Co., Ltd. | Tianjin, CN | US $330,000+ | 97% | ≤10h | <15% | 1 set | $68–$598 | Color, size, shape, logo, packaging, magnet type |

| Henan Baba Trading Co., Ltd. | Henan, CN | US $260,000+ | 100% | ≤1h | <15% | 1 set | $38–$264 | Color, material, size, logo, label |

| Dongguan Ruiyee Machinery Co., Ltd. | Guangdong, CN | US $190,000+ | 100% | ≤2h | <15% | 1 piece | $79–$495 | Color, material, size, logo, packaging, graphic |

| Yiwu Dongcheng Digital Technology Co., Ltd. | Zhejiang, CN | US $110,000+ | 94% | ≤3h | 16% | 1 set | $32–$124 | Color, size, logo, packaging, label |

| GED (Guangzhou) Import And Export Limited | Guangdong, CN | US $70,000+ | 100% | ≤8h | <15% | 1 piece | $19–$37 | Material, size, model-specific design |

Performance Analysis

Talent (Tianjin) leads in engineering breadth with high-end models supporting complex configurations, though response times lag behind peers. Henan Baba stands out for responsiveness (≤1h) and competitive pricing, ideal for urgent procurement. Dongguan Ruiyee offers wide diameter support (up to 75mm) and strong after-sales service visibility. GED delivers the lowest entry price point ($19), making it suitable for startups and DIY market entrants. Yiwu Dongcheng provides balanced performance but exhibits a slightly higher reorder rate, indicating potential variability in customer satisfaction. All top-tier suppliers support customization and ship globally with FOB terms common.

FAQs

How to verify button maker machine supplier reliability?

Assess on-time delivery history, response latency, and transaction volume. Request product specifications, assembly diagrams, and material certifications. Conduct video audits of production areas if possible. Validate past buyer feedback focusing on machine durability and dimensional accuracy.

What is the average sampling timeline?

Standard samples are typically produced within 7–14 days. Customized units requiring new dies or molds may take 20–30 days. Air shipping adds 5–10 days depending on destination.

Can suppliers ship button making machines worldwide?

Yes, most suppliers offer international shipping via air or sea freight. Confirm Incoterms (FOB, CIF), customs documentation, and voltage compatibility (110V/220V) prior to order placement.

Do manufacturers provide free samples?

Free samples are uncommon; however, many suppliers credit sample costs against future bulk orders. Sample fees typically range from $30–$100 depending on complexity.

How to initiate customization requests?

Submit detailed requirements including desired button size, closure type, production volume, and aesthetic preferences (color, logo placement). Reputable suppliers will respond with technical drawings, tooling quotes, and estimated timelines within 48–72 hours.