Using A Button Maker

Top sponsor listing

Top sponsor listing

1/29

1/29

1/12

1/12

1/10

1/10

1/6

1/6

1/9

1/9

1/10

1/10

1/13

1/13

About using a button maker

Where to Find Button Maker Suppliers?

China remains the central hub for button maker manufacturing, with key production clusters in Guangdong, Zhejiang, and Jiangsu provinces. Shenzhen and Yancheng have emerged as specialized centers for precision metal-forming machinery, hosting vertically integrated facilities that combine tooling, assembly, and packaging under one roof. These regions benefit from mature supply chains for dies, molds, and metal components—reducing material lead times by 20–30% compared to non-specialized zones.

Suppliers in these clusters typically operate semi-automated to fully manual production lines optimized for small-format metal制品 such as badge presses and fridge magnet machines. The proximity of raw material suppliers—including zinc alloy ingots, steel sheets, and UV-printable substrates—enables rapid prototyping and low-cost customization. Buyers can expect average MOQs between 1–5 sets, with standard lead times ranging from 7–15 days for off-the-shelf models. Economies of scale are evident in companies reporting annual online revenues exceeding US $300,000, indicating established export workflows and consistent output capacity.

How to Choose Button Maker Suppliers?

Procurement decisions should be guided by three core evaluation criteria:

Technical Capability Verification

Confirm whether the supplier specializes in button-making equipment or offers it as an adjunct product. Primary manufacturers like Yancheng Stik Pro Machinery Equipment Co., Ltd. focus exclusively on button presses and heat-forming tools, ensuring higher process consistency. Evaluate machine specifications including die-cut compatibility (e.g., 58mm round, 53x80mm rectangular), pressing force type (manual, semi-automatic), and mold interchangeability. For custom designs, verify support for hollow-out carving, foil stamping, and NFC integration where applicable.

Production & Quality Assurance Metrics

Prioritize suppliers demonstrating measurable performance indicators:

- On-time delivery rate ≥96%

- Response time ≤3 hours

- Reorder rate >15% (indicating customer retention)

- Customization capability across color, size, thickness, and branding options

Cross-reference claims with verifiable transaction data, such as documented order histories and repeat purchase rates. Manufacturers offering engraving, debossing, or multi-layer graphic application demonstrate advanced finishing capabilities.

Transaction Security and Compliance

While formal certifications (ISO, CE) are not universally listed, assess operational reliability through response efficiency and fulfillment accuracy. Favor suppliers providing detailed packaging design services, mold development, and sample validation prior to bulk production. Use secure payment structures—such as escrow or milestone-based releases—to mitigate risk, especially when sourcing from newer entities with limited compliance documentation.

What Are the Best Button Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Product Range | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Vistarts Crafts Co., Ltd. | Metal Crafts, Key Chains, Medals, Plaques | US $330,000+ | 100% | 23% | ≤1h | Yes (color, material, logo, NFC, packaging) | 14 products | Custom Manufacturer |

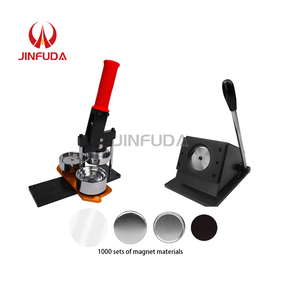

| Talent (Tianjin) Electronics Co., Ltd. | Button Makers, Fridge Magnets, Badge Machines | US $330,000+ | 96% | <15% | ≤10h | Yes (shape, size, magnet, label) | 5 products | Custom Manufacturer |

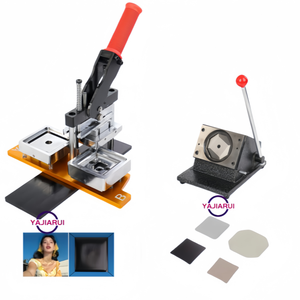

| Foshan Yajiarui Machinery Co., Ltd. | Packaging & Sealing Machines | US $130,000+ | 100% | <15% | ≤1h | Limited | 5 products | Not specified |

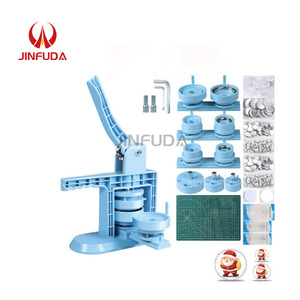

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines, Heat Presses | US $120,000+ | 100% | 17% | ≤3h | Basic (size, format) | 5 products | Not specified |

| Yiwu Chuxin Technology Co., Ltd. | Button Makers, Office Supplies | US $10,000+ | 85% | 20% | ≤1h | Minimal | 5 products | Not specified |

Performance Analysis

Shenzhen Vistarts and Talent (Tianjin) lead in revenue scale and customization depth, both operating as verified custom manufacturers with strong metallurgy and design capabilities. Despite lower responsiveness, Talent maintains high delivery reliability (96%), making it suitable for standardized industrial orders. Foshan Yajiarui leverages packaging machinery expertise but offers limited specialization in button makers, suggesting secondary market positioning. Yancheng Stik Pro stands out for dedicated equipment focus, though its customization scope is narrower. Yiwu Chuxin offers competitive pricing (as low as $15/unit) but exhibits lower on-time performance (85%), posing fulfillment risks for time-sensitive contracts.

FAQs

How to verify button maker supplier reliability?

Analyze on-time delivery records, reorder rates, and response times as proxies for operational stability. Request product videos or facility walkthroughs to confirm production setup. Validate machine functionality through physical or digital samples before scaling orders.

What is the typical MOQ and pricing range?

Most suppliers list MOQs at 1 set or even per piece, particularly for handheld models. Prices vary from $15 for basic 58mm manual presses to over $1,000 for semi-automatic refrigerator magnet lines. Bulk discounts are commonly available beyond 10 units.

Can suppliers customize button maker designs?

Yes, leading manufacturers support full customization including shape (round, square, rectangle), size (50mm–80mm), material (zinc alloy, steel), surface treatment (mirror gold, laser engraving), and packaging (card boxes, ribbon). Advanced options include NFC embedding and die-cast molds for branded housings.

Do suppliers offer samples?

Sample availability depends on complexity. Simple hand-press units may be provided at reduced cost or included with initial orders. Custom molds or engraved dies often require separate tooling fees ranging from $50–$200, refundable against future production runs.

What are common lead times and shipping options?

Standard item lead times average 7–15 days post-payment. Shipping via express carriers (DHL, FedEx) takes 3–7 days internationally; sea freight is economical for container loads, requiring 20–35 days depending on destination port clearance procedures.