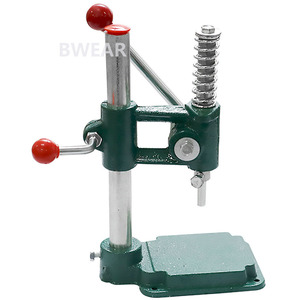

Button Making Tool

1/14

1/14

1/6

1/6

1/12

1/12

1/15

1/15

1/22

1/22

1/10

1/10

1/9

1/9

1/19

1/19

About button making tool

Where to Find Button Making Tool Suppliers?

China leads global production of button making tools, with concentrated manufacturing hubs in Zhejiang, Jiangxi, and Yiwu offering specialized industrial ecosystems. These regions host vertically integrated supply chains combining precision tooling, die-casting, and small-parts assembly under one network. Jiangxi and Yiwu serve as primary centers for DIY and craft-oriented equipment, supporting high-volume output of handheld presses and modular kits. Zhejiang’s machinery clusters focus on industrial-grade pneumatic systems and multi-form factor machines capable of processing round, square, and rectangular badges.

The regional infrastructure enables rapid prototyping and scalable production, with many suppliers operating facilities within 50km of component vendors for dies, molds, and pressing mechanisms. This proximity reduces lead times by up to 40% compared to offshore alternatives. Buyers benefit from flexible MOQs—ranging from single-unit sets to container-scale orders—and access to customization at minimal incremental cost. Average production cycles span 15–30 days for standard configurations, with express fulfillment options available for urgent procurement needs.

How to Choose Button Making Tool Suppliers?

Apply the following criteria to evaluate supplier suitability:

Production and Technical Capacity

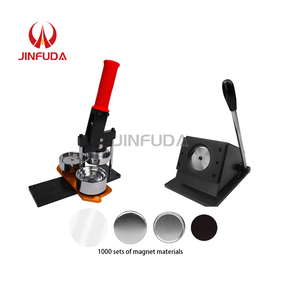

Assess whether manufacturers support required form factors (e.g., 58mm round, 50x50mm square, 80x53mm rectangle) and material compatibility (plastic, metal, fabric-covered). Prioritize suppliers with in-house mold design and CNC machining capabilities, which ensure consistency across batches. Pneumatic and semi-automated models should demonstrate structural durability and alignment precision to minimize misfires during operation.

Quality Assurance Metrics

Target suppliers with verified on-time delivery rates exceeding 95%. Response time under 3 hours indicates strong customer service infrastructure. Reorder rates below 20% may signal niche specialization or limited scalability, while higher rates (>20%) reflect customer satisfaction but require validation of consistent quality under volume pressure. Cross-reference self-reported performance with transactional data where available.

Customization and Compliance Readiness

Confirm capability for logo imprinting, packaging labeling, and graphic customization if branding is required. While not universally certified, leading suppliers adhere to internal quality management protocols equivalent to ISO 9001 standards. For export markets, verify compliance with destination-specific safety regulations, particularly for electric or pneumatic models involving mechanical force.

Procurement Safeguards

Utilize secure payment terms such as escrow or letter of credit for initial orders. Request samples before bulk procurement to assess build quality, ease of use, and press alignment accuracy. Evaluate tool ergonomics, die hardness, and retention mechanism integrity during testing. Confirm packaging durability for international shipping, especially for glass-reinforced or metallic components.

What Are the Best Button Making Tool Suppliers?

| Company Name | Specialization | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier | Customization |

|---|---|---|---|---|---|---|---|---|

| Jiangxi Mide Industrial Co., Ltd. | All-in-one & custom photo systems | $20–1,380 | 1 set | 96% | ≤3h | <15% | $380K+ | Color, material, size, logo, packaging, label, graphic |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Round, square, rectangular kits | $57–620 | 1 set | 100% | ≤3h | 18% | $120K+ | Limited to product line variants |

| Yiwu Chuxin Technology Co., Ltd. | Low-cost 58mm machines | $15–35 | 1 piece | 85% | ≤1h | 20% | $10K+ | Basic model variations |

| Wenzhou Banwei Garment Accessory Co., Ltd. | Fabric cover & hand press kits | $0.30–14.50 | 2–10 units | 100% | ≤7h | 20% | $20K+ | Packaging and minor accessory bundling |

| Yiwu Dingpin Trading Ltd. | Molds, magnetic snaps, hat buttons | $2.97–28 | 2 pieces | 100% | ≤2h | <15% | $4K+ | Dies and mold customization |

Performance Analysis

Jiangxi Mide offers the broadest customization scope and highest revenue volume, making it suitable for branded or retail-ready deployments. Yancheng Stik Pro stands out with a perfect on-time delivery record and diverse shape support, ideal for businesses requiring multiple badge formats. Yiwu Chuxin provides entry-level pricing with fast response times, though its lower delivery reliability warrants caution for time-sensitive contracts. Wenzhou Banwei and Yiwu Dingpin specialize in low-MOQ accessory components, serving micro-businesses and craft suppliers needing small-batch flexibility. All top-tier suppliers support sample orders, enabling functional evaluation prior to scale-up.

FAQs

What is the typical MOQ for button making tools?

Most suppliers offer MOQs of 1 set or 1 piece for complete machines, with component kits (e.g., dies, pliers) available in 2–10 unit quantities. Bulk pricing applies at 50+ units depending on model complexity.

How long does production and shipping take?

Manufacturing lead time averages 15–25 days for standard orders. Air freight adds 5–10 days; sea freight requires 25–40 days depending on destination. Expedited production (7–10 days) is available from select suppliers at a premium.

Can I customize the machine with my brand logo?

Yes, Jiangxi Mide and select others provide OEM services including logo engraving, custom color housings, and branded packaging. Minimum volumes may apply for full branding integration.

Do suppliers provide technical documentation?

Operational manuals are standard. CAD drawings and mold specifications are available upon request, particularly for customized dies or automated systems. Confirm language support (English/Chinese) before ordering.

Are spare parts and after-sales support available?

Core components like dies, plungers, and retaining rings are replaceable. Suppliers typically stock spares and offer replacement at 5–15% of unit cost. Direct communication channels remain open for troubleshooting, though formal warranty terms vary by vendor.