Diy Button Making

1/6

1/6

1/12

1/12

1/33

1/33

1/24

1/24

About diy button making

Where to Find DIY Button Making Suppliers?

China remains the global hub for DIY button making equipment and components, with key manufacturing clusters in Zhejiang, Jiangsu, and Guangdong provinces. Yiwu (Zhejiang) is a recognized center for small craft hardware and accessories, offering access to vast inventories of pre-cut blanks, pins, and decorative materials ideal for manual button kits. Nearby industrial zones in Foshan and Yancheng specialize in compact press machinery, leveraging localized metalworking and tooling infrastructure to produce cost-effective hand-operated and semi-automatic button makers.

These regions benefit from vertically integrated supply chains—combining die-casting, stamping, and assembly under one ecosystem—enabling rapid prototyping and scalable production. Buyers can expect lead times of 15–30 days for standard machine orders and immediate dispatch for consumable components. The proximity of raw material suppliers and component manufacturers reduces unit costs by 20–35% compared to Western equivalents, while supporting low minimum order quantities (MOQs) suitable for startups and craft distributors.

How to Choose DIY Button Making Suppliers?

Procurement decisions should be guided by technical capability, transaction reliability, and after-sales support. Use the following criteria to evaluate potential partners:

Equipment Specification & Compatibility

Confirm machine compatibility with desired button sizes (common diameters: 25mm, 38mm, 58mm, 75mm) and types (pin-back, magnet, sew-on). Verify whether kits include dies, base plates, and alignment tools. For resin or wooden buttons, ensure suppliers provide UV-resistant coatings or pre-sanded blanks if required.

Production Capacity & Scalability

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 1,000m² for dedicated machinery lines

- In-house tooling and mold-making capabilities for custom shape development

- Monthly output capacity above 5,000 units for machine suppliers

Cross-reference online revenue data and reorder rates to gauge operational stability and customer satisfaction.

Quality Assurance & Transaction Security

Prioritize suppliers with documented quality control processes. While formal ISO certification may be limited among smaller machinery producers, demand evidence of functional testing, material traceability, and packaging durability. Utilize secure payment mechanisms and request product videos or third-party inspection reports prior to shipment. Evaluate response time and language proficiency as proxies for post-sale service reliability.

What Are the Best DIY Button Making Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Yiwu Niucky Clothing Co., Ltd. | Buttons (Resin, Wood, Mixed Shapes) | $2.21–$7.99 per bag | 1 bag | 100% | ≤4h | $5,000+ | <15% |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines, Heat Press | $39–$620 per set | 1 set | 100% | ≤3h | $120,000+ | 17% |

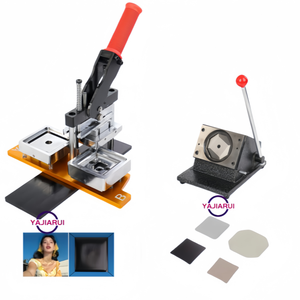

| Foshan Yajiarui Machinery Co., Ltd. | Square & Rectangular Button Presses | $59–$559 per set | 1 set | 100% | ≤1h | $130,000+ | <15% |

| Jiangsu Enters Industrial Co., Ltd. | Fridge Magnet & Badge Makers | $170–$639 per set | 1 set | 91% | ≤4h | $120,000+ | <15% |

| Yiwu Chuxin Technology Co., Ltd. | Digital Pin Badge Kits, Square Presses | $16–$190 per piece | 1 piece | 84% | ≤1h | $10,000+ | 20% |

Performance Analysis

Suppliers like Yancheng Stik Pro and Foshan Yajiarui demonstrate strong operational performance with 100% on-time delivery and high online revenue, indicating robust production systems and export experience. Foshan leads in responsiveness (≤1h), critical for iterative sourcing discussions. Yiwu Niucky stands out for consumables, offering sub-$3 MOQ pricing with flexible bag-based ordering ideal for retailers and educators. Jiangsu Enters provides mid-range machinery with moderate delivery reliability (91%), suggesting room for logistics optimization. Yiwu Chuxin offers the lowest entry-level pricing ($16) but has a higher reorder rate (20%) and lower on-time fulfillment, signaling potential consistency risks despite fast communication.

FAQs

What are typical MOQs for DIY button making machines?

Most suppliers set MOQ at 1 unit or set for machinery, enabling low-risk sampling. Consumables such as resin or wooden buttons are typically sold in pre-packed bags with no volume commitment.

How long do production and shipping take?

Standard machine orders are processed within 7–15 days. With air freight, international delivery takes 5–10 days; sea freight requires 25–40 days depending on destination. Blank button batches often ship within 48 hours due to stock availability.

Can suppliers customize button shapes or machine designs?

Yes, many suppliers offer OEM services for molds and machine branding. Custom dies for non-standard shapes (e.g., rectangles, ovals) require 2–4 weeks for development, with NRE fees ranging from $100–$500 based on complexity.

Are safety certifications available for button presses?

While most manual presses do not require CE or UL certification, suppliers serving EU/US markets often comply with basic mechanical safety standards. Request documentation on material hardness, pinch-point protection, and load testing where applicable.

Do suppliers provide digital templates or design support?

Select suppliers offer downloadable PDF templates for common button sizes. Full-service vendors may assist with layout formatting for inserts, especially when bundled with heat press or digital printing units.