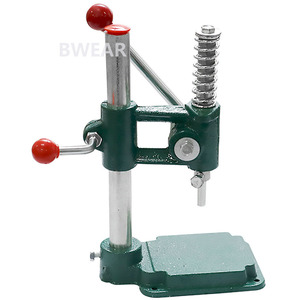

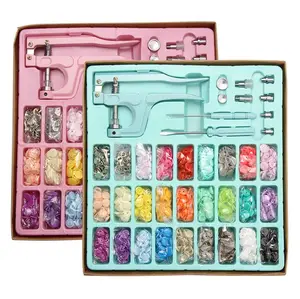

Covered Button Maker Tool

About covered button maker tool

Where to Find Covered Button Maker Tool Suppliers?

China remains the global epicenter for covered button maker tool manufacturing, with key production clusters concentrated in Zhejiang, Guangdong, and Yiwu regions. These industrial hubs offer vertically integrated supply chains combining precision metal stamping, mold fabrication, and assembly under one roof. Wenzhou and Foshan-based suppliers dominate mid-to-high volume production, leveraging proximity to steel and alloy suppliers to reduce material costs by 15–25% compared to non-specialized manufacturers.

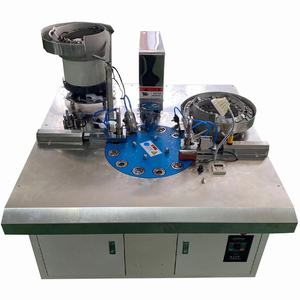

The region’s ecosystem supports rapid prototyping and scalable output, with many factories operating automated press lines capable of producing 5,000–10,000 units monthly per line. Buyers benefit from tight geographic clustering—component vendors, plating services, and logistics providers often operate within 30km—enabling lead times as short as 15–25 days for standard orders. Cost efficiencies stem from localized sourcing of zinc alloy, stainless steel, and die-cast molds, while flexible MOQs accommodate both small craft businesses and large garment manufacturers.

How to Choose Covered Button Maker Tool Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Production & Technical Capability

Assess whether suppliers maintain in-house mold design and CNC machining facilities, critical for custom die configurations. Prioritize those with multi-station hydraulic presses (minimum 20-ton capacity) ensuring consistent crimping force. Confirm compatibility with fabric thicknesses ranging from 0.5mm to 3mm and support for common button diameters (16L–24L). Video audits should verify organized production floors and calibrated tooling maintenance schedules.

Quality Assurance Protocols

While formal ISO 9001 certification is not universally present among smaller exporters, evidence of internal QC checkpoints—including pre-shipment inspection logs and defect sampling rates—is essential. Look for suppliers implementing 100% on-time delivery records and response times under 8 hours, indicators of operational discipline. Reorder rates above 20% suggest sustained customer satisfaction, particularly in competitive niches like DIY sewing tools.

Procurement & Transaction Safeguards

Favor suppliers offering Trade Assurance or escrow-compatible payment terms. Evaluate sample policies: most require full sample fees for single-piece requests but may credit these against bulk orders exceeding 2 sets. Benchmark pricing transparency—clear breakdowns of unit cost, packaging, and shipping minimize downstream disputes. For customization, request CAD drawings or physical prototypes before mass production.

What Are the Best Covered Button Maker Tool Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Wenzhou Banwei Garment Accessroy Co., Ltd. | Pliers, Rhinestones, Garment Beads | $0.26–14.50 | 2–10 bags/pieces | 100% | ≤8h | 22% | $20,000+ |

| Foshan Zeming Hardware Technology Co., Ltd. | Buttons, Belt Buckles, Eyelets | $18–350 | 1–2 sets | 100% | ≤3h | 26% | $20,000+ |

| Yiwu Dingpin Trading Ltd. | Buttons, Eyelets, Jewelry Tools | $3.20–28 | 2 pieces | 100% | ≤2h | <15% | $5,000+ |

| Yiwu Lianglishuo Trading Co., Ltd. | Eyelets, Buttons, Tool Sets | $0.01–50 | 1–100 pieces | 100% | ≤4h | <15% | $5,000+ |

| Foshan Jusfer Metal Products Co., Ltd. | Belt Buckles, Buttons, Eyelets | $27–925 | 1–2 sets | 84% | ≤12h | 25% | $20,000+ |

Performance Analysis

Foshan-based suppliers demonstrate superior responsiveness and higher-end production capacity, with Zeming Hardware achieving a 26% reorder rate and sub-3-hour average response time. Wenzhou Banwei offers aggressive pricing on entry-level tools ($0.26/unit), ideal for high-volume craft kits. Yiwu-based traders provide niche flexibility with ultra-low MOQs down to 1 piece, though lower reorder rates indicate less repeat business. Jusfer Metal stands out for semi-automatic machine offerings but lags in on-time delivery performance at 84%. Buyers seeking durable hand-press systems should prioritize suppliers quoting prices above $18/set, correlating with reinforced alloy construction and ergonomic design.

FAQs

What materials are commonly used in covered button maker tools?

Most tools use zinc alloy or carbon steel for dies and housings, with spring-loaded plungers made from tempered steel. Handles are typically coated steel or composite plastic for grip durability. High-end models incorporate wear-resistant coatings to extend mold life beyond 10,000 cycles.

What is the typical lead time for bulk orders?

Standard orders ship within 15–25 days after deposit confirmation. Custom molds add 7–10 days for development and testing. Air freight delivers samples in 5–7 days; sea freight takes 25–35 days depending on destination port.

Can suppliers customize button sizes or shapes?

Yes, most manufacturers support OEM/ODM requests for non-standard diameters (e.g., 12L, 30L) or specialty shapes (square, heart). Minimum order quantities for custom molds range from 2,000 to 5,000 units, with tooling costs between $100–$300 recoverable after volume thresholds.

Do suppliers provide free samples?

Sample availability varies. Some suppliers offer paid samples ($5–$30) deductible from future orders, while others require full freight and tooling charges upfront. Truly free samples are rare outside established buyer relationships.

Are electrical certifications required for import?

No electrical certifications are needed for manual button maker tools. However, if sourcing electric-powered pressing machines, CE or RoHS compliance becomes mandatory for EU markets, and UL listing may be required for North America.