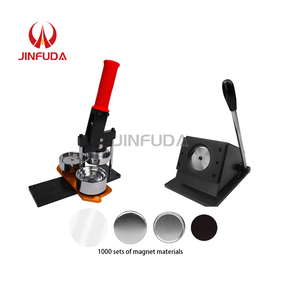

Button Maker Cutter

1/24

1/24

1/15

1/15

1/12

1/12

1/24

1/24

1/14

1/14

1/12

1/12

1/29

1/29

1/6

1/6

1/9

1/9

About button maker cutter

Where to Find Button Maker Cutter Suppliers?

China is the dominant hub for button maker cutter manufacturing, with concentrated supplier clusters in Yiwu and Wenzhou offering specialized expertise in small-scale metal forming and precision cutting tools. These regions host vertically integrated production ecosystems that combine die-cutting, stamping, and assembly operations within compact industrial zones. Proximity to raw material suppliers—particularly stainless steel, aluminum, and plastic molding facilities—enables cost efficiencies of 20–35% compared to Western producers.

The supply chain benefits from mature logistics infrastructure, allowing rapid fulfillment of both retail and bulk orders. Most manufacturers operate agile production lines capable of switching between standard sizes (e.g., 25mm, 37mm, 58mm) with minimal retooling downtime. Buyers gain access to flexible output capacities, ranging from single-unit kits for DIY markets to high-volume runs exceeding 10,000 units monthly. Key advantages include low minimum order quantities (MOQs), fast prototyping cycles (3–7 days), and compatibility with digital customization workflows.

How to Choose Button Maker Cutter Suppliers?

Prioritize these verification criteria when evaluating potential partners:

Technical Capability Verification

Confirm suppliers possess in-house tooling design and mold fabrication capabilities, particularly for multi-size button makers and interchangeable cutters. Look for evidence of CNC machining, hydraulic pressing, and quality-controlled calibration processes. For dual-function devices (e.g., round and rectangular cutters), verify mechanical durability through load testing documentation.

Production & Quality Metrics

Assess operational reliability using verifiable performance indicators:

- On-time delivery rate exceeding 95%

- Reorder rate above 25% as a proxy for customer satisfaction

- Average response time under 2 hours for inquiry resolution

Cross-reference online transaction volume (e.g., $50,000+ annual digital revenue) as an indicator of market presence and order-handling capacity.

Customization and Transaction Security

For branded or size-specific tooling, confirm support for OEM/ODM services including color, engraving, packaging, and labeling modifications. Prioritize suppliers offering third-party transaction protection and clear dispute resolution mechanisms. Request physical samples to evaluate ergonomics, cutting precision, and material finish before scaling procurement.

What Are the Best Button Maker Cutter Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Product Range | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Yiwu Chuxin Technology Co., Ltd | Button Making Machines, Filing Products, Badge Holders | US $10,000+ | 86% | 20% | ≤1h | 5 | 1 piece/set | $16–281 |

| Yiwu Wantu Machinery Equipment Co., Ltd. | Button Making Machines, Metal Crafts, Promotional Magnets | US $30,000+ | 100% | 16% | ≤3h | 5 | 1 pack/set | $32–99 |

| Yiwu Honyi Craft Factory | Decorative Objects, Heat Press Machines, Frames | US $190,000+ | 99% | 26% | ≤3h | 5 | 1 set | $50–685 |

| Wenzhou Baiwang Precision Machinery Co., Ltd. | Button Making Machines, Pin Badge Presses | US $50,000+ | 100% | 30% | ≤2h | 5 | 1 piece/set | $50–120 |

| Yiwu Dongcheng Digital Technology Co., Ltd. | Custom Button Makers, Digital Kits | US $110,000+ | 93% | <15% | ≤3h | 5 | 1 pack/set | $99–235 |

Performance Analysis

Wenzhou Baiwang Precision Machinery stands out with a 30% reorder rate and 100% on-time delivery, indicating strong product consistency and customer retention. Yiwu Honyi Craft Factory demonstrates scalability with the highest reported online revenue ($190,000+), though its pricing skews toward premium models like square fridge magnet systems. Yiwu Chuxin offers the widest price range ($16–281), suggesting adaptability across entry-level and professional segments. While most suppliers maintain MOQs of one unit, unit economics improve significantly at volumes above 50 sets. Custom manufacturers like Yiwu Dongcheng emphasize design flexibility but exhibit lower repeat order rates, signaling potential gaps in post-sale support or standardization.

FAQs

How to verify button maker cutter supplier reliability?

Evaluate on-time delivery history, reorder rate, and response speed as primary KPIs. Request product certifications (e.g., CE, RoHS) where applicable, particularly for electrical components or export to regulated markets. Conduct virtual factory audits to confirm in-house production versus trading activity.

What is the typical lead time for samples?

Standard sample processing takes 3–7 business days. Customized configurations involving new molds or branding elements require 10–15 days. Air shipping adds 5–10 days depending on destination.

Can suppliers accommodate custom designs?

Yes, verified custom manufacturers support modifications in size, shape (round, rectangle, heart), color, and packaging. Provide technical drawings or prototypes for accurate quoting. Minimum thresholds for custom tooling typically start at 500 units.

Do suppliers offer free samples?

Free samples are uncommon for machinery. Most suppliers charge full or partial fees, which may be credited toward future orders. Sample costs typically reflect material and handling expenses.

What are common payment and shipping terms?

Standard payment methods include T/T, L/C, and platform-secured transactions. Shipping options vary by weight and urgency—express couriers (DHL, FedEx) suit sample deliveries, while sea freight is economical for container-sized orders. Confirm FOB or CIF terms prior to order confirmation.