Vmc Machine Price Bfw

1/19

1/19

CN

CN

1/17

1/17

1/4

1/4

1/23

1/23

1/9

1/9

1/11

1/11

1/7

1/7

CN

CN

About vmc machine price bfw

Where to Find VMC Machine Suppliers with Competitive Pricing?

China remains the global epicenter for vertical machining center (VMC) production, with key manufacturing clusters in Shandong and Guangdong provinces driving cost efficiency and export volume. Shandong’s Jining and Taian regions host vertically integrated CNC machine tool facilities that leverage proximity to steel foundries and component suppliers, reducing material costs by 15–20% compared to non-integrated producers. Dongguan in Guangdong specializes in reconditioned and second-hand VMCs, offering refurbished Taiwan-origin machines that maintain high precision at reduced price points.

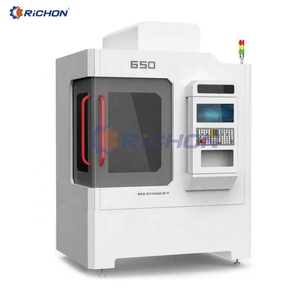

These industrial zones support rapid scalability through consolidated supply chains—raw casting, linear guide rail integration, spindle assembly, and final testing occur within compact geographic radii. This integration enables lead times of 30–45 days for standard models and supports flexible customization, including axis configuration (3-axis to 5-axis), tool magazine type, and control system selection (Fanuc, Siemens, or domestic equivalents). Buyers benefit from competitive pricing due to economies of scale, with entry-level VMC650 models starting under $12,000 and heavy-duty VMC1270 units priced up to $32,000.

How to Evaluate VMC Machine Suppliers?

Selecting a reliable supplier requires rigorous assessment across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Confirm adherence to ISO 9001 standards as a baseline for quality management. For international buyers, CE marking is essential for customs clearance in Europe. Request documentation on spindle runout tolerance (ideally ≤3μm), positioning accuracy (±0.005mm), and repeatability (±0.003mm). Verify inclusion of precision components such as BT40/BT50 tool holders, preloaded ball screws, and hardened guideways.

Production Capacity Verification

Assess infrastructure maturity through measurable indicators:

- Minimum factory area exceeding 5,000m² to ensure stable output

- In-house machining capabilities covering casting finishing, gear cutting, and electrical cabinet assembly

- Dedicated R&D teams capable of implementing custom configurations based on engineering drawings

Cross-reference on-time delivery rates (target ≥97%) with order fulfillment history. Suppliers achieving 100% on-time performance across multiple years demonstrate robust production planning.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with delivery and inspection. Prioritize suppliers offering sample units or factory audits via video tour to validate build quality. Conduct pre-shipment inspections to verify machine geometry, coolant system integrity, and control panel functionality against agreed specifications.

What Are the Leading VMC Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Shandong Gsk Cnc Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | US $730,000+ | 100% | ≤2h | 31% | Color, material, size, precision drawing, tool setter, packaging |

| Dongguan Jingzhan Machinery Equipment Co., Ltd. | Guangdong, CN | - | US $5,000+ | 100% | ≤5h | 50% | Limited (focused on used equipment) |

| Shandong Yijin Cnc Machine Tool Co., Ltd. | Shandong, CN | - | US $40,000+ | 100% | ≤1h | 50% | Size, logo, packaging, graphic |

| Taian Best Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $70,000+ | 100% | ≤2h | 100% | Color, material, size, logo, packaging |

| Dalian Haisen Machinery Co., Ltd. | Liaoning, CN | Multispecialty Supplier | US $250,000+ | 100% | ≤2h | 33% | Drawings, logo, packaging, multi-axis integration |

Performance Analysis

Suppliers like Taian Best Machinery stand out with a 100% reorder rate, indicating strong customer satisfaction despite moderate online revenue. Shandong-based manufacturers dominate responsiveness, with three suppliers answering inquiries within two hours. Dalian Haisen offers advanced customization, particularly for 4- and 5-axis configurations, supported by engineering expertise evident in their product range. Dongguan Jingzhan focuses on the secondary market, providing cost-effective used VMC850 and VMC1160 models from Taiwan brands, ideal for budget-conscious buyers seeking proven reliability. Shandong Gsk and Yijin offer competitive pricing on new machines, with models starting below $12,000, making them suitable for small to mid-sized workshops.

FAQs

What is the typical MOQ and pricing range for VMC machines?

Most suppliers set a minimum order quantity (MOQ) of 1 set, facilitating pilot purchases. New VMC650/VMC850 models range from $11,000 to $18,500, while heavy-duty models (VMC1160 and above) reach $32,000. Used or refurbished units are available from $12,000, primarily through Guangdong-based resellers.

How long does it take to fulfill a VMC machine order?

Standard delivery lead time ranges from 30 to 45 days after deposit confirmation. Custom configurations involving specialized spindles or control systems may extend lead time to 60 days. Pre-owned machines often ship faster, within 15–25 days.

Can suppliers customize VMC machines based on technical drawings?

Yes, leading suppliers accept OEM/ODM requests with full technical documentation. Customization includes worktable dimensions, spindle speed (8,000–24,000 RPM), ATC type, and CNC controller brand. Prototypes or modified units can typically be produced within 4–6 weeks upon approval.

Do VMC machine suppliers provide after-sales support?

Most suppliers offer basic installation guides and remote troubleshooting. Extended support—including on-site technician deployment, training, and spare parts supply—should be negotiated upfront. Warranty periods vary from 12 to 24 months, covering critical components like spindle and linear guides.

Are shipping and logistics handled by the supplier?

Yes, experienced exporters manage FOB and CIF shipping arrangements. Full-container loads (1–2 machines per 40ft container) are common. Buyers should confirm insurance coverage, port handling fees, and destination import regulations for industrial machinery prior to shipment.