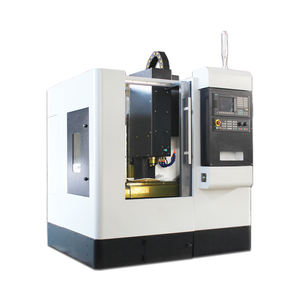

Vmc Machine Bfw

CN

CN

About vmc machine bfw

Where to Find VMC Machine BFW Suppliers?

China remains the global hub for vertical machining center (VMC) production, with key manufacturing clusters in Liaoning, Shanghai, and Shandong provinces. These regions host vertically integrated facilities that specialize in CNC machine tools under industrial designations such as BFW, leveraging localized supply chains for cast iron beds, precision spindles, and linear guides. The Dalian and Wafangdian areas in Liaoning are particularly notable for heavy-duty machining centers, benefiting from legacy state-owned tool group technologies now commercialized through private partnerships.

Suppliers in these zones operate within mature ecosystems where component sourcing, heat treatment, CNC assembly, and quality testing occur within tightly coordinated networks. This integration enables competitive pricing—ranging from $11,000 for compact models to over $348,000 for horizontal machining centers—with lead times averaging 30–45 days for standard configurations. Buyers gain access to scalable production capacity, with leading suppliers reporting online revenues exceeding $700,000 annually and maintaining on-time delivery rates above 93%. Customization options including control systems (Fanuc, Syil), worktable dimensions, ATC configurations, and branding are widely supported across the supplier base.

How to Choose VMC Machine BFW Suppliers?

Selecting a reliable supplier requires systematic evaluation of technical, operational, and transactional indicators:

Technical Compliance

Verify compatibility with international standards such as ISO 9001 for quality management. While explicit certification data is not always disclosed, consistent on-time delivery performance (≥93%) and responsive communication (response times ≤2 hours for top-tier suppliers) serve as proxies for process discipline. For export markets, ensure machine controllers comply with regional electrical and safety norms—particularly Fanuc or Siemens-based systems preferred in North America and Europe.

Production Capability Audits

Assess infrastructure maturity using available metrics:

- Facility scale inferred from product range: Suppliers listing 5+ VMC models (e.g., VMC650, VMC850, VMC1160, VMC1370) typically maintain dedicated production lines

- In-house engineering capacity demonstrated by customization depth—top suppliers offer adjustments to spindle speed, axis travel, tool magazine type, and CNC interface

- Integration of advanced components such as drum-type tool changers (24-tools standard) and high-speed spindles up to 8,000 rpm

- Cross-reference reorder rates (up to 42%) as an indicator of customer satisfaction and post-sales support effectiveness

Transaction Safeguards

Prioritize suppliers with verifiable transaction histories and structured fulfillment processes. Use incremental order scaling—start with a single-unit purchase to evaluate build quality and documentation accuracy before committing to bulk procurement. Confirm packaging protocols (wooden crates with anti-corrosion protection) and shipping terms suitable for sea freight consolidation. Engage third-party inspection services upon arrival to validate mechanical alignment, geometric accuracy, and controller functionality against purchase specifications.

What Are the Best VMC Machine BFW Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Scope | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Genertec Dalian Machine Tool (wafangdian) Co., Ltd. | VMC850Q, VMC1000Q, VMC1160, HMC63H | $710,000+ | 100% | ≤1h | 42% | Color, material, size, logo, packaging, label, graphic | $32,220 – $350,000 |

| Zaozhuang Wojie CNC Machinery Co., Ltd. | VMC650, VMC1160, XH7124, 5-axis CNC | $550,000+ | 100% | ≤2h | 33% | Machine size, axis count, color, precision, table size, ATC, control system, spindle dimensions, packaging | $12,500 – $26,000 |

| Shanghai Sumore Industrial Co., Ltd. | VMC650, VMC855, VMC1370, M400-M500 | $120,000+ | 100% | ≤3h | 25% | Color, material, size, logo, packaging, label, graphic | $11,000 – $39,999 |

| Shenzhen Integrity Industry Co., Ltd. | VMC850B, VMC1160, VMC1370, T-640 Mini | $120,000+ | 93% | ≤2h | 15% | Tool post, color, material, size, spindle bore, logo, packaging, label, graphic | $16,200 – $40,170 |

| Elite Frontier Enterprises Inc. | VMC855, VMC1160, 5-axis CNC, Fanuc System | - | - | ≤5h | - | Limited public details; offers 5-axis and Fanuc-integrated models | $18,850 – $110,357 |

Performance Analysis

Genertec Dalian stands out with the highest reorder rate (42%) and fastest response time (≤1 hour), indicating strong operational reliability and customer service. Its product lineup spans mid-range VMCs to high-end horizontal machining centers priced above $348,000, suggesting robust engineering and manufacturing capabilities. Zaozhuang Wojie CNC distinguishes itself through extensive customization breadth, supporting 5-axis upgrades and precision tuning, making it suitable for specialized applications. Shanghai Sumore offers the most cost-competitive entry-level VMCs starting at $11,000, ideal for small workshops or educational use. Shenzhen Integrity provides balanced performance but has a lower reorder rate (15%), signaling potential gaps in long-term client retention. Elite Frontier, while offering premium Fanuc-equipped models, lacks transparency in delivery and reorder metrics, increasing procurement risk.

FAQs

How to verify VMC machine supplier reliability?

Evaluate suppliers based on documented delivery performance (target ≥97%), response consistency (≤2 hours), and customization depth. Request machine test run videos, electrical schematics, and controller interface samples prior to purchase. Cross-check company registration details and transaction volume trends where available.

What is the average sampling timeline for VMC machines?

Sample or demo unit production typically takes 25–40 days depending on configuration complexity. Standard 3-axis models require approximately 30 days, while 5-axis or dual-pallet systems may extend to 45 days. Air freight shipping adds 7–12 days globally; sea freight ranges from 20–35 days depending on destination port.

Can suppliers ship VMC machines worldwide?

Yes, established manufacturers support international logistics via FOB, CIF, or DDP terms. Confirm inclusion of export documentation (packing list, commercial invoice, bill of lading) and compliance with import regulations for heavy machinery in target markets. Sea freight is standard for full-container loads due to equipment weight and dimensional constraints.

Do manufacturers provide free samples?

Full-machine samples are generally not provided free of charge due to high production costs. However, some suppliers may apply sample fees toward subsequent bulk orders. Demonstrations via live video calls or factory test runs are commonly offered at no cost.

How to initiate customization requests?

Submit detailed technical requirements including desired axis travel (X/Y/Z), spindle power (kW/rpm), tool magazine capacity, CNC controller brand (Fanuc, Syil, etc.), table size, and automation readiness. Reputable suppliers will respond with updated quotations, 3D layout drawings, and estimated lead times within 48–72 hours.