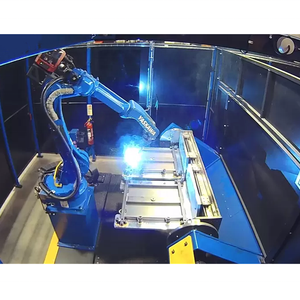

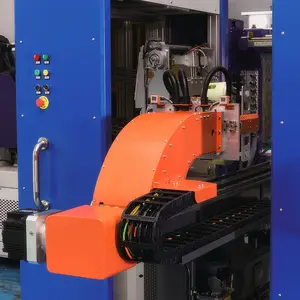

Yaskawa Robot

1/33

1/33

1/3

1/3

1/3

1/3

1/3

1/3

1/15

1/15

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

About yaskawa robot

Where to Find Yaskawa Robot Suppliers?

China serves as a central hub for industrial automation equipment sourcing, with key supplier clusters concentrated in Shandong and Henan provinces. These regions host specialized manufacturers offering integration solutions centered on Yaskawa robotic systems, leveraging established supply chains for motion control components, CNC subsystems, and welding peripherals. Shandong-based suppliers benefit from proximity to Jinan’s machinery export zone, enabling streamlined logistics for heavy equipment shipments. Henan's Zhengzhou corridor supports high-volume production through integrated metal fabrication networks, reducing component lead times by 20–25% compared to non-clustered facilities.

Suppliers in these zones typically operate vertically integrated workshops equipped with CNC machining centers, robotic calibration bays, and electrical assembly lines. This infrastructure supports turnkey delivery of Yaskawa-powered systems—including handling robots, welding arms, and collaborative CNC-integrated units—with average production cycles of 30–45 days for standard configurations. Buyers gain access to scalable output capacity, localized technical talent, and flexible customization options across payload classes (6–180 kg) and axis configurations (4–8 axes).

How to Choose Yaskawa Robot Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional criteria:

Technical Integration Capability

Verify supplier experience in configuring Yaskawa Motoman series robots (e.g., GP12, GP180, AR2010, MPX3500). Confirm compatibility with peripheral systems such as laser welders, positioners, and vision-guided modules. Request documentation of completed integrations, including system schematics and controller programming protocols.

Production Infrastructure Assessment

Evaluate the following benchmarks:

- Facility size supporting dedicated assembly zones for robotic cells

- In-house engineering teams capable of path optimization and safety interlock design

- On-site testing rigs for cycle time validation and repeatability measurement

Cross-reference supplier claims with on-time delivery performance (target ≥97%) and response efficiency (≤4 hours).

Quality and Transaction Assurance

Prioritize suppliers demonstrating compliance with ISO 9001 standards or equivalent quality management systems. While CE marking is frequently cited in product listings, validate actual certification status through official registries. Utilize secure payment mechanisms that link disbursement to post-delivery inspection outcomes. Conduct pre-shipment audits via video walkthroughs of final assembly and functional testing procedures.

What Are the Best Yaskawa Robot Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Jinan Lingyu International Trade Co., Ltd. | Shandong, CN | CNC Robots, 6-Axis Arms, Collaborative Units | US $40,000+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging, graphics |

| Zhengzhou King Shine Auto Technology Co., Ltd. | Henan, CN | Welding Robots, 6-Axis Hydraulic Arms | US $90,000+ | 100% | ≤4h | <15% | N/A |

| Jinan Suntec Cnc Machinery Co., Ltd. | Shandong, CN | 6-Axis Light Robot Arms, CNC-Integrated Systems | US $40,000+ | 100% | ≤4h | <15% | N/A |

| Shanghai Jiesheng Robot Co., Ltd. | Shanghai, CN | Handling Robots, Painting & Welding Systems | — | 100% | ≤4h | - | N/A |

| Gongboshi Robot Technology Co., Ltd. | Guangdong, CN | Motoman GP Series, AR2010, MPX3500 | US $20,000+ | 100% | ≤3h | <15% | Color, material, size, logo, packaging, graphics |

Performance Analysis

Suppliers like Zhengzhou King Shine report higher online transaction volumes (US $90,000+), indicating robust export activity and market penetration. Jinan Lingyu stands out for responsiveness (≤1 hour) and customization breadth, making it suitable for buyers requiring branded or dimensionally tailored robotic cells. Shanghai Jiesheng offers application-specific expertise in painting and heavy-duty handling systems, though public reorder metrics are unavailable. Gongboshi demonstrates strong alignment with Yaskawa’s GP-series platforms, with pricing transparency across multiple configurations. All listed suppliers maintain perfect on-time delivery records, suggesting reliable fulfillment processes despite varying scale.

FAQs

What is the typical MOQ for Yaskawa robot systems?

Minimum order quantities are generally set at 1 set or unit, allowing low-volume procurement for pilot deployments or process validation. Bulk orders may unlock incremental pricing discounts, particularly for multi-unit integrations.

What lead time should be expected?

Standard delivery windows range from 30 to 45 days after order confirmation, depending on complexity. Customized welding cells or large-payload handling robots (e.g., GP180) may require up to 60 days for assembly and factory acceptance testing.

Can suppliers integrate Yaskawa robots with existing production lines?

Yes, several suppliers offer integration services including PLC interfacing, HMI development, and safety circuit design. Technical specifications such as I/O requirements, communication protocols (EtherNet/IP, PROFINET), and workspace constraints must be provided prior to engineering commencement.

Do suppliers provide technical support post-purchase?

Support availability varies. Leading suppliers offer remote troubleshooting, commissioning assistance, and training programs. Confirm service scope—especially availability of English-speaking engineers—before contract finalization.

Are spare parts and controllers included in the package?

Most listings include the robot arm, controller, and teaching pendant as a complete unit. Peripheral components (end-effectors, cables, positioners) are often quoted separately. Clarify inclusion terms during quotation review to avoid downstream cost discrepancies.