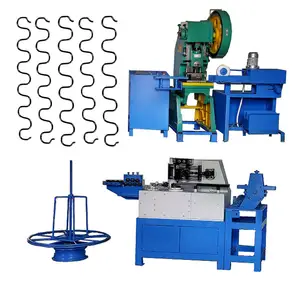

Zig Zag Spring Making Machine

CN

CN

About zig zag spring making machine

Where to Find Zig Zag Spring Making Machine Suppliers?

China remains the central hub for zig zag spring making machine production, with key manufacturing clusters concentrated in Jiangsu and Guangdong provinces. These regions host vertically integrated industrial ecosystems that specialize in metal forming and furniture component machinery. Nanjing, in Jiangsu Province, has emerged as a core center for precision spring equipment manufacturing, supported by a dense network of steel wire suppliers, CNC machining workshops, and automation engineers. Foshan and Dongguan in Guangdong offer agile production models suited for both high-volume output and customized configurations.

The concentration of technical expertise and supply chain proximity enables efficient prototyping and rapid scaling. Manufacturers benefit from localized access to raw materials such as high-carbon steel wire (SWRH82B, 65Mn) and galvanized wire, reducing material lead times by 10–15 days compared to offshore alternatives. Buyers can expect standard delivery windows of 25–40 days for non-customized machines, with production capacities ranging from small-scale benchtop units to fully automated CNC-controlled lines capable of producing 80–120 springs per minute.

How to Choose Zig Zag Spring Making Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and transaction security:

Technical Capability Assessment

Verify machine specifications align with intended applications—particularly wire diameter compatibility (typically 1.8–4.0mm), coil pitch adjustability, and integration with downstream packaging or conveyor systems. Prioritize suppliers offering CNC-controlled models with programmable logic controllers (PLCs) for consistent spring geometry. Confirm support for multiple spring types: zig-zag (sinuous), z-arc, wave, and snake springs used in sofa and mattress frames.

Production Infrastructure Verification

Evaluate supplier capabilities through the following indicators:

- Facility specialization in metal forming or furniture machinery (evidenced by product listing diversity)

- In-house R&D or engineering teams capable of customization (e.g., adjustable tension settings, multi-axis bending)

- On-time delivery performance exceeding 95%

- Response time under 3 hours for technical inquiries

Cross-reference operational metrics with actual product listings and pricing tiers to identify capacity scalability.

Quality and Transaction Assurance

While formal certifications like ISO 9001 or CE are not uniformly listed, prioritize suppliers demonstrating consistent quality control through verifiable on-time delivery records (100% reported by leading vendors). Use secure payment mechanisms and request functional test videos prior to shipment. For long-term partnerships, initiate sample orders to evaluate build quality, noise levels, and operational stability under continuous load.

What Are the Best Zig Zag Spring Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier |

|---|---|---|---|---|---|---|---|---|

| Foshan Kailiheng Hardware Co., Ltd. | Foshan, CN | Furniture Making Machines (34) | $4,870–62,653 | 1 set | 100% | ≤1h | - | - |

| Dongguan Xinsheng Hardware Machinery Co., Ltd. | Dongguan, CN | Customization-focused | $6,500–25,800 | 1 pc/set | 75% | ≤3h | 33% | US $40,000+ |

| Nanjing New Donor Machinery Equipment Co., Ltd. | Nanjing, CN | Other Metal & Metallurgy Machinery (1263) | $17,000–25,800 | 1 set | 100% | ≤9h | - | - |

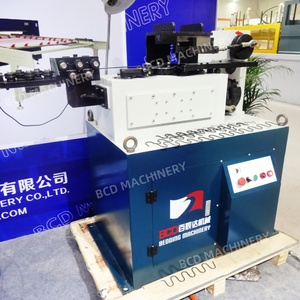

| Nanjing Bcd Bedding Machinery Co., Ltd. | Nanjing, CN | Furniture Making Machines (126) | $800–5,600 | 1 set | 100% | ≤1h | <15% | US $20,000+ |

| Nanjing Bang Win Imp & Exp Co., Ltd. | Nanjing, CN | Other Metal & Metallurgy Machinery (1379) | $17,000–25,800 | 1 set | 100% | ≤5h | <15% | US $30,000+ |

Performance Analysis

Nanjing-based suppliers dominate in consistency, with three companies reporting 100% on-time delivery rates and competitive pricing across mid-to-high-end models. Foshan Kailiheng offers the widest price range, indicating capability to serve both budget-conscious buyers and those requiring high-speed, industrial-grade production lines. Nanjing Bcd Bedding Machinery stands out for affordability, offering entry-level models from $800, though reorder rates suggest lower customer retention. Dongguan Xinsheng differentiates through customization options—including color, wire diameter, and mechanical labeling—supported by a strong reorder rate of 33%. Buyers seeking cost-effective solutions for low-volume production should consider sub-$5,000 models, while large-scale furniture manufacturers may prefer CNC-enabled systems priced above $25,000 for higher throughput and precision.

FAQs

How to verify zig zag spring making machine supplier reliability?

Assess reliability through on-time delivery history, response time consistency, and product specialization depth. Request demonstration videos showing machine operation with specified wire gauges. Validate claims about automation level (manual vs. CNC) and inquire about after-sales technical support availability.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set across all major suppliers. Lead times range from 20–40 days depending on customization complexity. Standard models are often available for immediate production, while CNC-integrated or dual-head configurations may require additional calibration time.

Can suppliers customize machine specifications?

Yes, many suppliers offer customization for wire diameter (1.8–4.0mm), spring pitch, bending angles, and motor power. Dongguan Xinsheng and Nanjing Bang Win explicitly list mechanical and labeling modifications. Technical drawings or sample spring profiles should be provided to initiate design adjustments.

Do suppliers provide installation and training support?

While not universally offered, some suppliers include remote setup guidance via video or manuals. For advanced CNC systems, request pre-shipment factory acceptance testing (FAT) and ask if on-site technician deployment is available at additional cost.

Are there cost differences between manual and automatic models?

Significant differences exist: fully automatic CNC models range from $17,000–$25,800, whereas semi-automatic or basic winding machines start as low as $800. Higher-priced units deliver greater speed, repeatability, and reduced labor input, suitable for industrial environments. Lower-cost models are appropriate for small workshops with intermittent production needs.