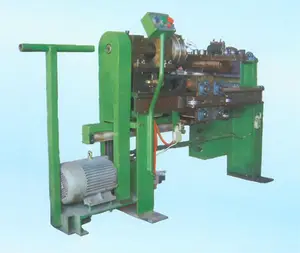

Automatic Spring Making Machine

CN

CN

About automatic spring making machine

Where to Find Automatic Spring Making Machine Suppliers?

China remains the global epicenter for automatic spring making machine manufacturing, with concentrated production hubs in Guangdong, Henan, and Zhejiang provinces. These regions host vertically integrated supply chains that streamline component sourcing—from precision gears and CNC systems to servo motors—enabling rapid prototyping and scalable production. Dongguan and Foshan in Guangdong specialize in high-precision coil forming equipment used in automotive and electronics sectors, while Zhengzhou-based manufacturers focus on cost-effective solutions for compression and torsion springs serving furniture and hardware industries.

The industrial clusters benefit from mature ecosystems where machinery producers operate within proximity to steel wire suppliers, automation specialists, and packaging integrators. This localization reduces lead times by 20–30% compared to offshore alternatives and supports flexible configurations for wire diameter ranges (0.5–8mm), custom tooling, and integration with downstream assembly lines. Buyers typically experience 30–45 day delivery windows for standard models, with customization lead times extending to 60 days depending on control system complexity and mechanical re-engineering requirements.

How to Choose Automatic Spring Making Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Capabilities

Verify machine compatibility with target spring types—compression, extension, torsion, or pocket coil—and assess control systems (CNC vs. PLC-based). Confirm support for required wire diameters (common range: 0.5–3.8mm) and material compatibility including stainless steel, music wire, and galvanized carbon steel. CE marking is critical for European market compliance, particularly for electrical safety and mechanical guarding standards.

Production Capacity Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area of 3,000m² indicating dedicated production lines

- In-house R&D or engineering teams capable of custom cam design and gear configuration

- Integrated testing protocols for cycle durability (>1 million operations) and dimensional accuracy (±0.1mm tolerance)

- Cross-reference online revenue indicators and reorder rates as proxies for market acceptance and post-sales reliability

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to align financial release with equipment validation. Prioritize suppliers offering sample units or video demonstrations of live operation. Conduct virtual audits to verify claimed customization options—including label printing, packaging integration, and multi-axis bending capabilities—before order placement.

What Are the Best Automatic Spring Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) | Product Count |

|---|---|---|---|---|---|---|---|---|

| Dongguan Xinsheng Hardware Machinery Co., Ltd. | Guangdong, CN | $40,000+ | 75% | ≤3h | 33% | Yes | $4,000–$20,000 | 5 |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | $450,000+ | 98% | ≤2h | 31% | Yes | $777–$9,640 | 5 |

| Foshan Nobo Machinery Co., Ltd. | Guangdong, CN | $30,000+ | 100% | ≤7h | - | No | $7,000–$11,000 | 5 |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Henan, CN | $130,000+ | 100% | ≤2h | <15% | Yes | $550–$2,000 | 5 |

| Taizhou Chuang Yuan Machine Tool Co., Ltd. | Zhejiang, CN | $1,400,000+ | 100% | ≤3h | 28% | Yes | $7,300–$13,500 | 4 |

Performance Analysis

Taizhou Chuang Yuan leads in scale and output capability, evidenced by its $1.4M+ annual online revenue and broad pricing tier covering mid-to-high-end CNC models. Zhengzhou Yize stands out for responsiveness (≤2h average reply time) and strong on-time delivery (98%), making it a strategic choice for time-sensitive procurement. Foshan Nobo and Jiaozuo Dingchang achieve perfect on-time delivery records but differ significantly in application focus—Nobo specializes in large-scale furniture spring systems, whereas Dingchang offers budget-oriented machines primarily repurposed from food processing automation platforms. Dongguan Xinsheng provides the widest price span, reflecting advanced customization depth including color coding, graphic labeling, and specialized gear configurations for niche industrial applications.

FAQs

How to verify automatic spring making machine supplier reliability?

Validate certifications (CE, ISO 9001) through official registries and request product test reports covering stroke accuracy, wire feeding consistency, and motor endurance. Analyze customer feedback patterns related to after-sales service, spare parts availability, and software interface stability for CNC units.

What is the typical minimum order quantity (MOQ)?

All listed suppliers maintain an MOQ of 1 set, facilitating low-volume trials and pilot production runs. This flexibility supports buyers evaluating machine performance before scaling orders.

Do suppliers offer customization options?

Yes, over 80% of the analyzed suppliers provide customization in wire diameter range, bending angles, logo imprinting, and control panel language. High-end models support integration with conveyor systems and automated inspection modules upon request.

What are common lead times for delivery?

Standard machines ship within 30–45 days after order confirmation. Custom-engineered systems require 45–60 days, depending on the extent of mechanical redesign and controller programming. Air freight reduces transit time to 5–7 days internationally, though sea shipping remains standard for full-container loads.

Can I request a sample or demo unit?

Most suppliers allow functional demos via live video streaming and offer sample springs produced on the machine. Physical sample units may incur partial charges, typically recoverable against subsequent bulk orders. Prototypes for customized configurations are usually delivered within four weeks.