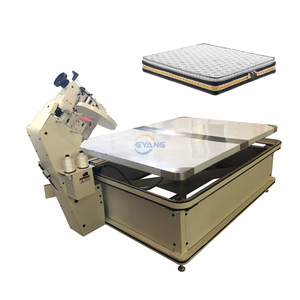

Automatic Mattress Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

About automatic mattress making machine

Where to Find Automatic Mattress Making Machine Suppliers?

China remains the central hub for automatic mattress making machine manufacturing, with key industrial clusters concentrated in Zhejiang and Henan provinces. These regions host vertically integrated supply chains that support full-cycle production—from foam processing and quilting to tape edge sewing and final rolling. Ningbo in Zhejiang has emerged as a core center for furniture machinery, leveraging proximity to port infrastructure and a mature ecosystem of component suppliers specializing in industrial automation systems.

The clustering effect enables streamlined operations, with many manufacturers operating facilities within 50km of material suppliers and logistics hubs. This integration supports faster turnaround times—typically 30–60 days for standard configurations—and cost efficiencies due to localized sourcing of steel, control panels, and pneumatic systems. Buyers benefit from scalable output capacity, with leading suppliers capable of fulfilling bulk orders of 10+ units monthly. The region also supports customization in voltage (220V/380V), control interfaces (PLC or touchscreen), and integration with downstream packaging lines.

How to Choose Automatic Mattress Making Machine Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international safety and performance benchmarks. CE marking is essential for European market access, indicating compliance with machinery directives. For high-volume buyers, request documentation on motor efficiency ratings, electrical panel IP protection levels, and noise output (typically ≤75 dB). Verify compatibility with common mattress materials such as memory foam, polyurethane, coir, and nonwoven fabrics.

Production Capability Audits

Assess supplier infrastructure through verifiable metrics:

- Facility size supporting dedicated assembly and testing zones

- In-house engineering teams for custom modifications (e.g., adjustable roller widths, auto-flipping mechanisms)

- Integration of CNC fabrication and welding for frame precision

Cross-reference claimed capabilities with actual order fulfillment data, particularly on-time delivery rates and response times.

Transaction Safeguards

Prioritize suppliers offering third-party inspection options prior to shipment. Evaluate financial reliability through verified revenue indicators and reorder rates. A reorder rate above 15% suggests customer satisfaction with product durability and after-sales service. Conduct sample testing to validate stitch consistency, seam strength, and system stability under continuous operation before scaling procurement.

What Are the Best Automatic Mattress Making Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Product Range (USD) | Verified Manufacturer |

|---|---|---|---|---|---|---|---|

| Ningbo Jiangbei Esun Machinery Co., Ltd. | Foam Machinery, Quilting Machines, Furniture Making Machines | 100% | ≤20h | - | - | $1,000–$40,000 | Yes |

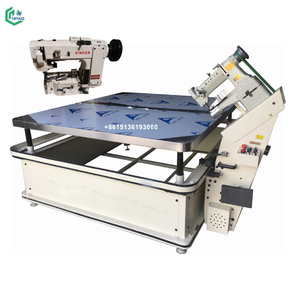

| Henan Gyang Machinery Co., Ltd. | Sewing Machines, Food Processing Machinery | 100% | ≤3h | <15% | US $110,000+ | $1,000–$2,300 | No |

| Ningbo Mushung Import And Export Co., Ltd. | Furniture Making Machines, Foam Machinery, Mattresses | 100% | ≤12h | <15% | US $90,000+ | $7,000–$250,000 | No |

| Qingdao Yisitaike Machinery Co., Ltd. | Nonwoven Machines, Carding Machines | 100% | ≤10h | - | - | $75,000–$200,000 | No |

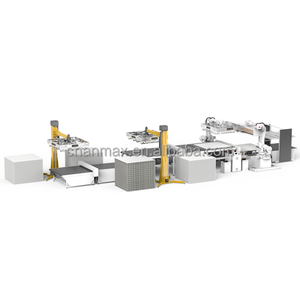

| Hangzhou Fuyang D&T Industry Co., Ltd. | PU Foam Production Lines, Mattress Equipment | 100% | ≤3h | 100% | US $410,000+ | $9,900–$165,000 | Yes |

Performance Analysis

Hangzhou Fuyang D&T Industry stands out with a 100% reorder rate and strong online transaction volume, indicating consistent buyer confidence and export readiness. Its focus on fully automatic PU foam production lines caters to large-scale mattress producers requiring turnkey solutions. Ningbo Mushung offers the widest price range, reflecting capability in both mid-tier quilting systems and high-end continuous foaming lines. Henan Gyang positions itself competitively in entry-level automatic sewing machines, though its lower average pricing correlates with limited customization scope. Suppliers based in Zhejiang generally exhibit higher investment in automation and process control, while Henan-based vendors emphasize rapid communication and cost-sensitive configurations.

FAQs

How to verify automatic mattress making machine supplier reliability?

Validate certifications such as CE or ISO 9001 through official registries. Request factory audit reports or video walkthroughs confirming in-house production. Analyze transaction history for consistent on-time delivery and responsive communication. Third-party inspection services can verify machine functionality pre-shipment.

What is the typical lead time for automatic mattress machines?

Standard models require 30–45 days for production and testing. Customized systems, especially continuous foaming or thermo-bonded lines, may take 60–90 days depending on complexity. Air freight reduces shipping time to 5–7 days; sea freight averages 20–35 days globally.

Do suppliers offer customization options?

Yes, most manufacturers support adjustments in machine width, voltage, control interface language, and integration with existing production layouts. High-end suppliers provide CAD drawings and PLC programming modifications for seamless line integration.

What are common MOQ and pricing structures?

Minimum order quantity is typically 1 set. Entry-level tape edge sewers start around $1,000–$2,000, while fully automatic rolling and foaming lines exceed $100,000. Bulk orders may qualify for container consolidation and discounted FOB pricing.

Can these machines handle different mattress types?

Yes, modern automatic systems are adaptable to memory foam, spring-core, coir, and hybrid designs. Key factors include adjustable pressure settings, programmable stitching patterns, and interchangeable molds for foam shaping. Confirm material compatibility with the supplier before procurement.