An air conditioning unit that freezes over is more than just a nuisance—it can halt cooling entirely, spike energy bills, and lead to costly repairs if ignored. Ice forming on the evaporator coil or refrigerant lines is not normal and usually points to an underlying issue with airflow, refrigerant levels, or system maintenance. The good news is that many causes of AC freeze-ups are preventable and often fixable without professional help—especially when caught early.

Understanding why your AC is freezing allows you to take timely action, avoid long-term damage, and maintain efficient home comfort during hot months.

Why Does an AC Freeze Up?

At first glance, it seems counterintuitive: an air conditioner designed to cool your home ends up covered in ice. But the science behind it is straightforward. Your AC removes heat from indoor air by circulating refrigerant through an evaporator coil. As warm air passes over this cold coil, moisture condenses and cools down. However, if the coil gets too cold—below 32°F (0°C)—the moisture freezes, forming a layer of ice that grows over time.

This typically happens due to one of three factors: restricted airflow, low refrigerant levels, or mechanical failure within the system. Each contributes to a drop in pressure and temperature at the evaporator coil, triggering frost buildup.

Common Causes of AC Freezing

1. Dirty Air Filter

The most frequent culprit behind frozen coils is a clogged air filter. When dust and debris accumulate, airflow into the system drops significantly. Without enough warm air passing over the coil, its temperature plummets, causing condensation to freeze.

2. Blocked or Closed Vents

Furniture, rugs, or closed dampers can obstruct supply or return vents. This reduces overall airflow, mimicking the effect of a dirty filter. Even a few blocked registers can disrupt system balance and contribute to freezing.

3. Low Refrigerant Levels

Refrigerant absorbs heat as it circulates. If there's a leak or undercharge, the pressure inside the evaporator coil drops, lowering its temperature beyond safe limits. Unlike airflow issues, refrigerant problems require a licensed technician to diagnose and recharge safely.

“Even a small refrigerant leak can cause major performance issues and lead to compressor damage if not addressed.” — James Laredo, HVAC Technician with 18 years of field experience

4. Dirty Evaporator Coil

Over time, the evaporator coil itself collects dust and grime, insulating it and reducing heat absorption. This forces the coil to run colder for longer periods, increasing the risk of freezing. Cleaning the coil annually helps maintain efficiency.

5. Malfunctioning Blower Motor or Fan

If the blower fan isn’t running at full capacity—or stops intermittently—airflow collapses. Causes include worn bearings, failed capacitors, or electrical faults. A weak or stalled blower starves the coil of warm air, setting the stage for ice formation.

6. Thermostat Issues or Short-Cycling

A faulty thermostat may signal the AC to run too frequently or for too short a duration. This prevents consistent airflow and can result in temperature imbalances that promote freezing, especially in humid environments.

Step-by-Step Guide to Thawing a Frozen AC

If you notice ice on your indoor unit or refrigerant lines, shut the system down immediately to prevent further damage. Follow these steps to safely thaw and assess the problem:

- Turn off the cooling function at the thermostat. Switch to \"fan only\" or turn the system completely off.

- Cut power to the unit at the circuit breaker to ensure safety during thawing.

- Allow natural thawing—this can take 4 to 12 hours depending on ice thickness. Do not chip away at the ice; this can damage coils.

- Place towels around the indoor unit to catch dripping water and prevent floor damage.

- Inspect and replace the air filter once thawed. Look for signs of heavy soiling or pet hair buildup.

- Check all supply and return vents to ensure they’re open and unobstructed.

- Restart the system and monitor airflow and cooling performance over the next few hours.

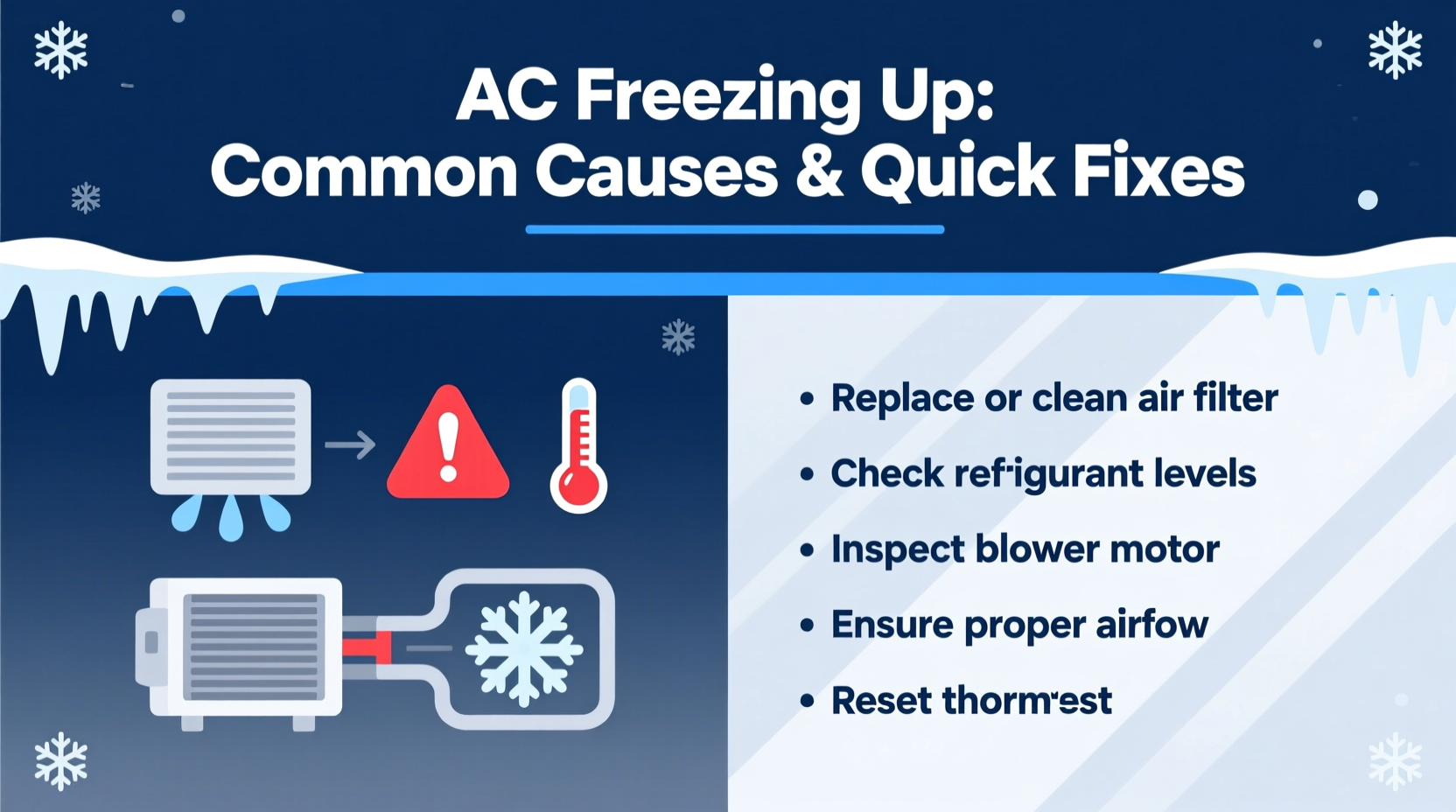

Quick Fixes You Can Do Today

Many freeze-up issues stem from simple oversights. Try these actionable solutions before calling a technician:

- Replace the air filter with a clean, compatible model (check MERV rating).

- Vacuum return grilles and supply vents to remove dust buildup.

- Ensure ceiling fans are rotating counterclockwise to improve air circulation.

- Clear space around indoor and outdoor units to allow unrestricted airflow.

- Verify thermostat settings—make sure it’s not set too low or running continuously.

When to Call a Professional

While some fixes are DIY-friendly, certain issues demand expert attention. Consider scheduling a service call if:

- The unit refreezes within 24 hours of thawing.

- You hear unusual noises (hissing, grinding) from the indoor or outdoor unit.

- There’s visible refrigerant leakage (oil stains near copper lines).

- The blower fan isn’t running or cycles erratically.

- Your home takes much longer to cool than usual.

| Issue | DIY Fix? | Requires Pro? |

|---|---|---|

| Dirty air filter | Yes | No |

| Blocked vents | Yes | No |

| Dirty evaporator coil | Limited access | Yes (for deep cleaning) |

| Low refrigerant | No | Yes (leak detection & recharge) |

| Blower motor failure | No | Yes |

| Thermostat malfunction | Possible replacement | Yes (if wiring or calibration issue) |

Mini Case Study: The Overlooked Filter

In summer 2023, a homeowner in Phoenix noticed their second-floor rooms weren't cooling properly. After checking the thermostat and outdoor unit, they discovered thick ice coating the indoor air handler. They turned off the system and began troubleshooting. Upon inspection, the air filter—last changed 10 months prior—was completely clogged with dust and pet hair. After replacing the filter and allowing 8 hours for thawing, the AC resumed normal operation. No further issues occurred after monthly filter checks were implemented. This case highlights how a simple maintenance task prevented unnecessary service calls and extended system life.

Preventative Checklist to Avoid Future Freeze-Ups

Stay ahead of AC problems with this seasonal checklist:

- ✅ Replace or clean air filters every 1–3 months.

- ✅ Inspect supply and return vents for obstructions.

- ✅ Schedule annual HVAC maintenance (spring tune-up recommended).

- ✅ Clean evaporator and condenser coils as part of routine service.

- ✅ Check refrigerant levels during professional servicing.

- ✅ Monitor thermostat performance and battery status.

- ✅ Keep indoor humidity below 60% using ventilation or dehumidifiers.

FAQ

Can I use a hairdryer to speed up thawing?

No. Applying direct heat can damage the evaporator coil or melt insulation on electrical components. Allow the unit to thaw naturally for safety and longevity.

How long should I wait before turning the AC back on?

Wait until all ice has melted and the system is completely dry—typically 6 to 12 hours. Running the fan-only mode afterward helps evaporate leftover moisture.

Will a frozen AC increase my electric bill?

Yes. A frozen system works harder to cool your home, leading to longer run times and higher energy consumption. It also risks compressor burnout, which is expensive to repair.

Conclusion

An AC freezing up is a clear warning sign—but one that often comes with manageable solutions. By understanding the root causes and taking prompt, informed action, you can restore cooling performance and protect your investment. Regular maintenance, attentive monitoring, and timely repairs keep your system running efficiently year after year.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?