A pressure washer that fails to build adequate pressure is one of the most common frustrations for homeowners and professionals alike. Whether you're cleaning driveways, decks, or siding, low or no pressure renders the machine ineffective. The good news is that most issues are diagnosable and fixable without replacing the entire unit. Understanding the core components and their roles allows you to pinpoint the problem efficiently and restore full performance.

Understanding How Pressure Is Built

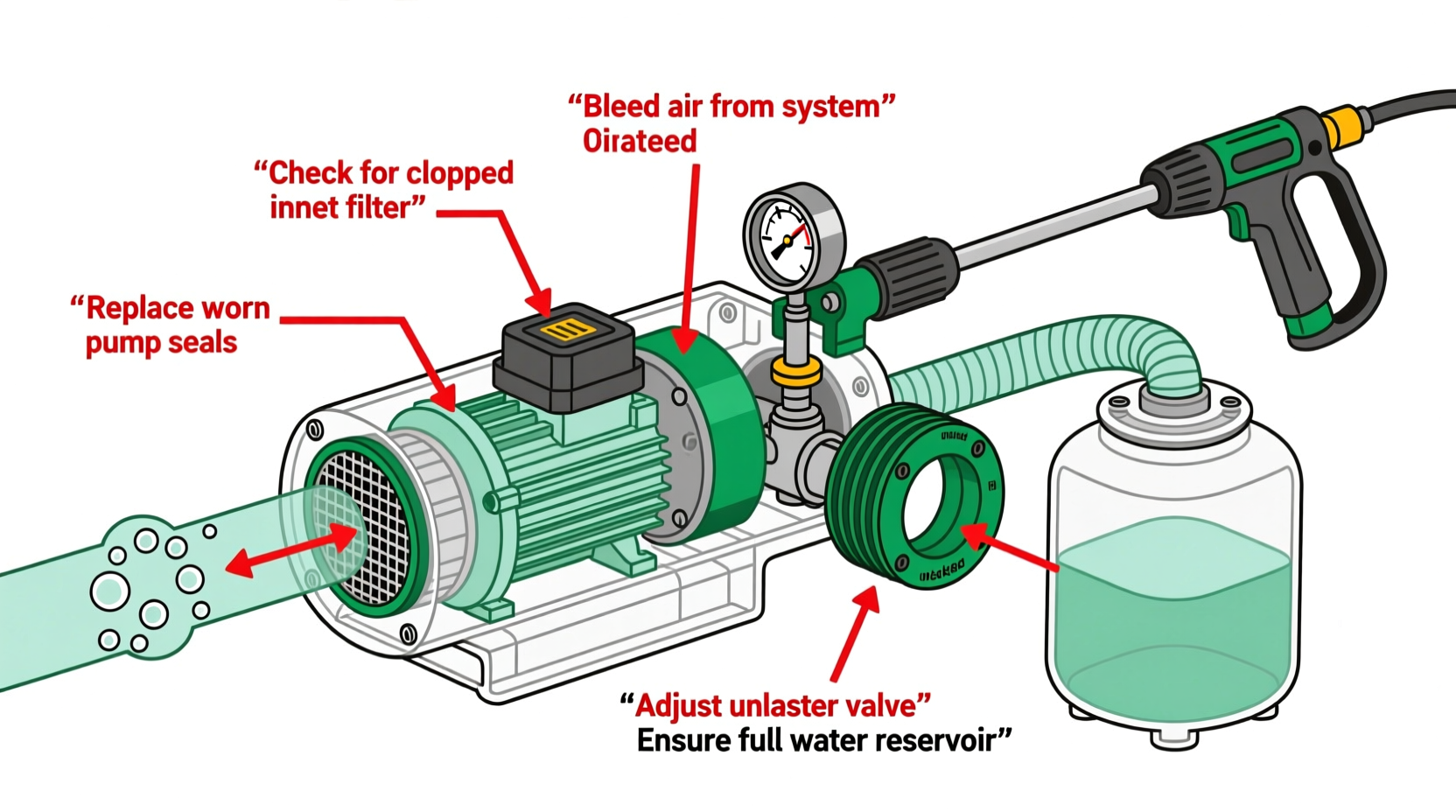

Pressure in a washer is created through a combination of water flow, pump operation, and nozzle dynamics. The high-pressure pump—typically driven by an electric motor or gas engine—draws water from a source and compresses it before sending it through the wand and nozzle. Any disruption in this system can result in reduced or no pressure. Common culprits include clogs, worn seals, air intake, faulty unloader valves, or insufficient water supply.

Before diving into complex repairs, confirm that your equipment is receiving clean, consistent water at the correct flow rate (measured in gallons per minute, or GPM). Most residential pressure washers require 4–6 GPM. Low input flow alone can prevent proper pressure buildup, regardless of pump condition.

Step-by-Step Troubleshooting Guide

Follow this logical sequence to isolate and resolve the issue:

- Check the water supply. Ensure the garden hose is fully open, free of kinks, and connected to a functioning spigot. Use a dedicated outdoor faucet with full pressure—not an indoor sink or filtered line.

- Inspect the inlet filter. Many units have a fine mesh screen where the hose connects. Remove and clean it under running water.

- Verify the nozzle size. A clogged or oversized nozzle affects perceived pressure. Test with a known-clean standard tip (e.g., 15° red nozzle).

- Examine all hoses and connections. Look for cracks, bulges, or loose fittings. Replace damaged high-pressure hoses immediately.

- Bleed trapped air from the system. With the trigger closed, turn on the water and let it run through the pump for 30 seconds before starting the engine or motor.

Common Causes and Fixes

Pump Issues

The pump is the heart of the pressure washer. If it’s not functioning correctly, pressure will not build. Worn piston seals, damaged check valves, or a malfunctioning crankshaft can all lead to poor compression.

Listen for unusual noises like knocking or squealing. These often indicate internal wear. If the pump runs but produces weak spray, internal seals may be failing. In such cases, rebuilding the pump with a seal kit (available by model) is often more cost-effective than replacement.

Faulty Unloader Valve

The unloader valve redirects water flow when the trigger is released, preventing overheating and maintaining system integrity. If stuck open or improperly adjusted, it bypasses water continuously, reducing output pressure.

To test: Disconnect the high-pressure hose and start the unit. If water sprays from the unloader port (usually on the side of the pump), the valve is likely stuck. Disassemble, clean with solvent, and inspect the spring and plunger. Reassemble and adjust according to manufacturer specs.

Clogged Nozzles or Filters

Mineral deposits or debris can restrict water flow. Even a partially blocked nozzle drastically reduces pressure. Remove the nozzle tip and soak it in white vinegar for 30 minutes. Use a thin wire or pin to clear any residue, then rinse thoroughly.

Similarly, the inline filter between the hose and pump inlet should be checked monthly. A clogged filter starves the pump of water, leading to cavitation and loss of pressure.

Suction Side Air Leaks

If air enters the system before the pump, it disrupts water compression. This commonly occurs at hose connections, O-rings, or cracked fittings. Signs include sputtering spray, inconsistent pressure, or a hissing sound.

To locate leaks, run the washer with the high-pressure gun closed. Spray soapy water on joints and fittings. Bubbles will form at leak points. Replace damaged O-rings or tighten connections as needed.

Worn or Damaged High-Pressure Hose

Internal lining collapse or external abrasion can restrict flow. Inspect the hose for soft spots, bulges, or visible damage. Even minor kinks can reduce efficiency. Replace if over five years old or showing signs of wear.

“Over 60% of pressure loss cases we see stem from overlooked inlet restrictions or air ingestion. Always start simple.” — Mark Reynolds, Commercial Equipment Technician with 18 years of field experience

Troubleshooting Checklist

- ✅ Confirm water supply is fully open and unrestricted

- ✅ Clean inlet filter and nozzle tip

- ✅ Inspect high-pressure hose for damage or kinks

- ✅ Bleed air from the pump before startup

- ✅ Test with a different, clean nozzle

- ✅ Listen for abnormal pump noises

- ✅ Check for leaks at all connections using soapy water

- ✅ Verify unloader valve function and adjustment

Do’s and Don’ts Table

| Do’s | Don’ts |

|---|---|

| Use fresh, clean water sources | Run the washer without water (dry firing) |

| Flush the system after each use | Use hot water on cold-water models |

| Store with pump lubricant (if recommended) | Ignore small leaks or drips |

| Replace worn O-rings and seals promptly | Force disassembly with damaged tools |

| Consult the manual for model-specific guidance | Assume the pump is dead without testing |

Real-World Example: Garage Weekend Warrior Fix

Tom, a homeowner in Colorado, noticed his gas-powered pressure washer wouldn’t clean his concrete patio effectively. He replaced the nozzle and checked the hose, but still saw weak output. After reading up, he inspected the inlet filter—a small brass screen near the water connection. It was packed with sediment from his well-fed outdoor spigot. After soaking it in vinegar and rinsing, he reassembled the unit. Pressure returned instantly. Tom now cleans the filter every three uses and keeps a spare on hand.

This case highlights how a simple $2 part can bring a seemingly broken machine back to life. Regular maintenance prevents minor issues from becoming major failures.

Frequently Asked Questions

Why does my pressure washer start strong but lose pressure quickly?

This often indicates a failing check valve inside the pump or an unloader valve that’s not sealing properly. As the pump heats up, worn components expand slightly, worsening the leak. Let the unit cool and retest. If pressure returns temporarily, internal wear is likely.

Can I use my pressure washer with a rain barrel or portable tank?

Yes, but ensure the water source provides sufficient gravity-fed flow (at least 4 GPM). Use a suction hose with a built-in filter and prime the pump manually if needed. Avoid drawing from murky or debris-filled containers, as they accelerate clogging.

Is it worth repairing an old pressure washer?

Generally, yes—if the frame, motor, and pump housing are intact. Pump rebuild kits cost $30–$70 and can extend life by several seasons. However, if the engine is seized or the frame is rusted through, replacement may be more economical.

Conclusion: Restore Power and Extend Lifespan

A pressure washer not building pressure is rarely a terminal issue. By methodically checking water supply, filters, hoses, and internal components, most problems can be resolved with basic tools and minimal cost. The key is prompt attention and regular maintenance. Don’t wait for total failure—clean filters, inspect seals, and store properly after each use.

With these steps, you’ll not only fix today’s issue but also prevent tomorrow’s breakdown. Take action now: pull out your washer, run through the checklist, and reclaim its full cleaning power.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?