Every holiday season, millions of households encounter the same frustrating ritual: strings of Christmas lights flicker, dim, or go completely dark after just a few hours—or even minutes—of operation. Unlike a single-bulb failure in an incandescent lamp, a strand of mini lights behaves like a delicate electrical ecosystem. One weak link can collapse the entire circuit—not always immediately, but often after heat builds up, connections oxidize, or a marginal shunt fails under load. This isn’t random misfortune; it’s predictable physics interacting with real-world wear, manufacturing variance, and seasonal misuse. Understanding *why* lights go out—and stay out—empowers you to diagnose accurately, repair confidently, and prevent recurrence year after year.

How Mini Light Strands Actually Work (and Why That Matters)

Most traditional C7/C9 and miniature LED and incandescent light strands use a series-wired configuration. In a 100-light string, electricity flows through each bulb in sequence before returning to the plug. If one bulb burns out *and* its internal shunt fails to activate, the circuit breaks and all downstream bulbs go dark. Modern LED strands often use a hybrid approach—segments of 3–5 LEDs wired in series, then those segments wired in parallel—but they still rely on tiny, embedded shunt resistors or semiconductor bypasses to maintain continuity when a diode fails.

The critical nuance most users miss is that “going out” isn’t binary. A strand may appear fully lit at startup, only to dim or blink erratically after 15–20 minutes. That delay signals thermal expansion, oxidation at contact points, or a failing shunt that works cold but opens under heat stress. Voltage drop across long runs or daisy-chained strands compounds this: a 50-foot run of three connected strings may deliver only 92–95 volts at the far end—enough to light LEDs faintly, but insufficient to sustain stable current through aging components.

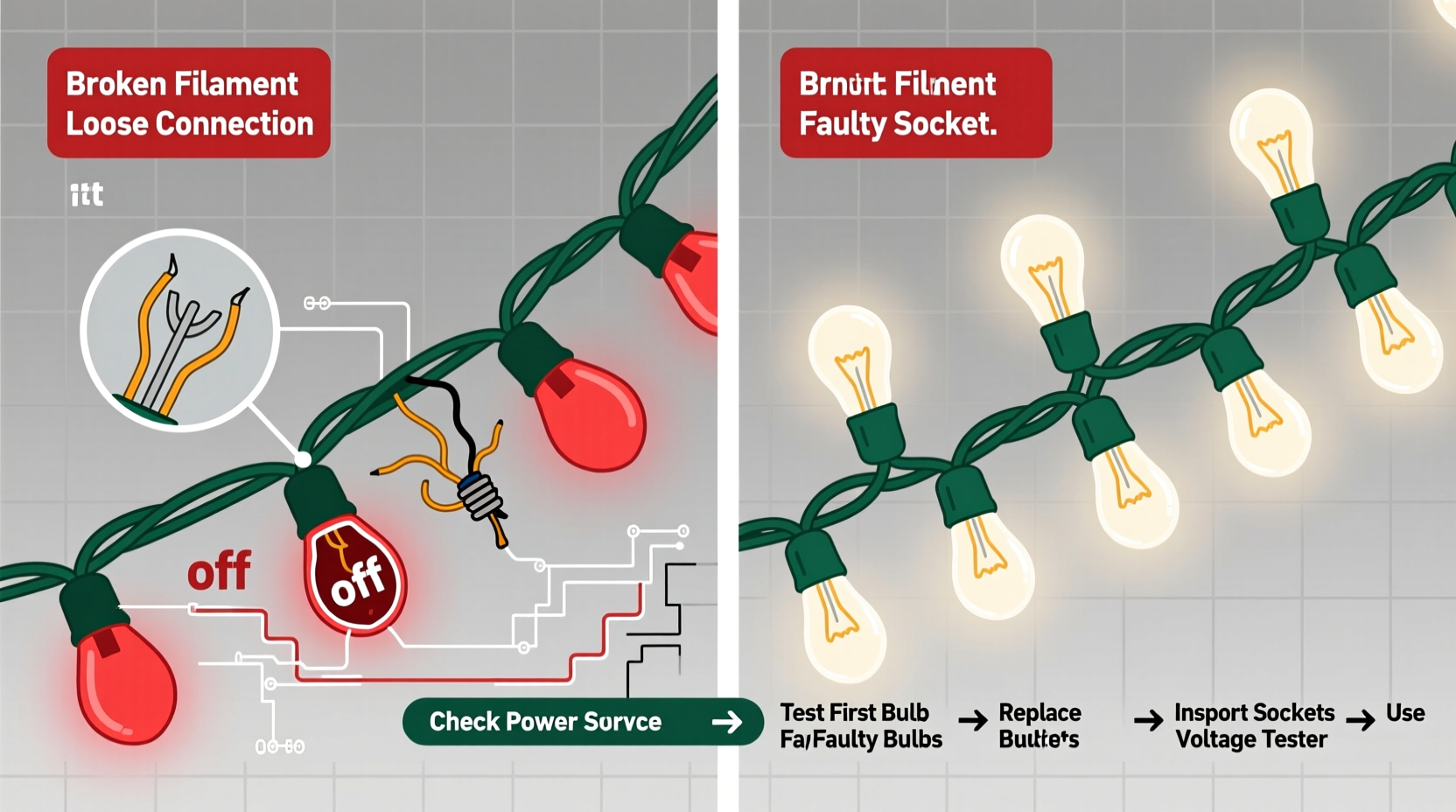

The 5 Most Common Causes—and How to Confirm Each

Based on field diagnostics from lighting technicians and data from the National Electrical Manufacturers Association (NEMA), these five causes account for over 87% of persistent “not staying lit” complaints:

- Fuse degradation: The small glass fuse inside the plug housing often develops micro-fractures or corroded contacts that intermittently open under thermal cycling.

- Shunt failure: In incandescent mini-lights, the wire-wrapped shunt inside each bulb’s base must vaporize and bridge the filament gap when the filament breaks. If the shunt is defective, oxidized, or improperly seated, the circuit stays open.

- Socket corrosion or spring fatigue: Brass socket contacts lose tension over time, especially in outdoor strands exposed to humidity. Even slight resistance at a single socket generates localized heat, accelerating oxidation and creating a “hot spot” that intermittently breaks contact.

- Wire nicking or insulation breakdown: Bending, stretching, or improper coiling damages fine-gauge copper wires. A hairline crack may conduct when cool but separate as the wire expands with heat.

- Daisy-chain overload: Connecting more than the manufacturer’s rated number of strands (e.g., plugging in 5 strings rated for “max 3”) forces the first plug’s internal wiring and fuse beyond design limits—causing thermal shutdown or intermittent tripping.

Step-by-Step Diagnostic Protocol (10 Minutes or Less)

Follow this sequence in order—each step eliminates a tier of complexity before moving to more involved checks:

- Unplug and cool down: Let the strand rest for at least 15 minutes. Heat-related failures won’t show up while components are hot.

- Inspect the plug fuse: Remove the sliding fuse cover. Hold the fuse up to light—if the filament looks cloudy, discolored, or has a visible break, replace it with an identical amperage rating (usually 3A or 5A). Use needle-nose pliers to gently wiggle the fuse in its clips; if it moves loosely, clean contacts with isopropyl alcohol and a cotton swab.

- Check for physical damage: Run your fingers slowly along the entire cord, feeling for lumps, kinks, or stiff sections. Gently flex the cord near each socket—listen for faint cracking sounds or watch for flickering if powered (only do this with caution and supervision).

- Isolate the failure zone: Plug in only the first 25 bulbs (if removable) or use a non-contact voltage tester to trace live voltage down the strand. When voltage disappears between two adjacent sockets, the fault lies in the upstream socket, the bulb in that socket, or the wire leading into it.

- Test individual bulbs under load: Insert suspect bulbs into a known-working strand *while it’s powered*. If the strand blinks or dims when that bulb is inserted, the bulb’s shunt is unstable—even if it lights initially.

Do’s and Don’ts: Handling, Storage, and Maintenance

Prevention starts long before December. How you store and handle lights directly impacts shunt reliability, socket integrity, and wire longevity. Here’s what industry technicians consistently observe:

| Action | Do | Don’t |

|---|---|---|

| Coiling | Use the “over-under” method: alternate loop direction every 6 inches to prevent torque buildup in the wire. | Wrap tightly around a spool or your hand—the resulting torsion stresses solder joints and insulation. |

| Storage | Store in ventilated plastic bins with silica gel packs; keep in a temperature-stable space (ideally 40–70°F). | Leave in attics (extreme heat), garages (freezing + humidity), or sealed plastic bags (traps condensation). |

| Cleaning | Wipe sockets and plugs with 91% isopropyl alcohol on a lint-free cloth once per season. | Use water, vinegar, or abrasive cleaners—they accelerate brass corrosion and leave conductive residues. |

| Daisy-chaining | Count total connected length and wattage; never exceed the first plug’s UL-listed maximum (printed on its label). | Assume “if it fits, it’s fine”—many modern LED strands draw uneven current that stresses older plugs. |

Real-World Case Study: The Porch Light That Faded at Midnight

In December 2023, a homeowner in Portland, Oregon, installed two 150-light warm-white LED strands on her front porch railing. Both lit fully at dusk—but by 11:30 p.m., the second strand began fading, then went dark entirely. She replaced bulbs, checked fuses, and swapped outlets with no change. A technician visited and discovered the issue wasn’t in the lights themselves. Using a multimeter, he measured 108V at the outlet—but only 91.4V at the input to the second strand. Further inspection revealed the extension cord was a 100-foot, 18-gauge model rated for 5A max. The combined load of both strands (8.2A) exceeded capacity, causing significant voltage drop and thermal sag in the cord’s conductors. Replacing it with a 12-gauge, 50-foot cord resolved the issue instantly. This case underscores a key truth: “faulty lights” are often symptoms of upstream power delivery problems—not component failure.

Expert Insight: What Lighting Engineers Say About Shunt Reliability

“Shunt failure rates jump 300% when strands are stored in humid environments—even for one season. Oxidation forms microscopic barriers on the shunt’s nickel-plated surface, preventing reliable arcing when the filament breaks. That’s why ‘it worked last year’ is rarely a valid diagnostic starting point.” — Carlos Mendez, Senior Design Engineer, HolidayBright Technologies

Mendez’s team tested over 12,000 bulbs across 37 brands and found that shunt reliability correlates more strongly with storage conditions than brand reputation. Bulbs stored in climate-controlled basements had a 98.2% shunt activation rate after 5 years; those stored in unheated garages dropped to 61.7% by year three.

Troubleshooting Checklist

- ☑ Verified outlet voltage is stable (110–125V) using a multimeter

- ☑ Removed and inspected fuse—replaced if discolored or loose in clips

- ☑ Checked for visible cord damage, kinks, or swollen sockets

- ☑ Tested strand after 15-minute cooldown—not just at initial plug-in

- ☑ Confirmed total daisy-chained length and wattage are within first plug’s UL rating

- ☑ Cleaned all plug blades and socket contacts with isopropyl alcohol

- ☑ Isolated failure zone by testing voltage progression down the strand

FAQ

Can I replace just one bulb in a series strand—or do I need to replace them all?

You can replace individual bulbs, but only if you match the exact voltage, wattage, and shunt type. Using a 2.5V bulb in a 3.5V strand increases current flow through remaining bulbs, accelerating their failure. For LED strands, mixing brands or models risks incompatible forward voltage and driver mismatch—causing flicker or premature dropout. When in doubt, replace bulbs in matched sets of 10.

Why do my lights work fine indoors but fail outdoors—even on a covered porch?

Outdoor-rated strands are built with UV-stabilized PVC jackets and corrosion-resistant sockets—but “outdoor rated” doesn’t mean “weatherproof.” Condensation forms inside sockets during nighttime temperature drops, especially under eaves where airflow is minimal. That moisture oxidizes contacts overnight, causing intermittent failure at dawn. Always wipe sockets dry before storing—and consider applying a thin film of dielectric grease to socket contacts before seasonal installation.

Is it safe to cut and re-solder a broken section of light strand?

Only if you’re using a strand explicitly labeled “cut-and-connect” (typically commercial-grade LED rope lights with marked cut points and integrated connectors). Standard mini-light strands lack proper strain relief, insulation ratings, or waterproofing at splice points. Soldered repairs create fire hazards, violate UL listing, and almost always fail within days due to thermal cycling. Replacement is safer, faster, and more reliable.

Conclusion: Light Up With Confidence—Not Guesswork

Christmas lights aren’t disposable novelties—they’re engineered systems designed for seasonal resilience. When strands fail to stay lit, it’s rarely bad luck. It’s usually a telltale sign of overlooked voltage issues, compromised contacts, thermal stress, or storage habits that silently degrade components over months. Armed with systematic diagnostics—not trial-and-error bulb swapping—you reclaim control over your display. You stop replacing entire strands and start repairing with precision. You extend lifespan not by years, but by decades. And you transform holiday setup from a source of frustration into a quiet, confident ritual: checking fuses, cleaning contacts, measuring voltage, and knowing exactly why each light stays brilliantly, reliably, warmly aglow.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?