Pre-strung artificial Christmas trees promise convenience: no tangled wires, no ladder climbs, no guesswork about spacing or voltage. Yet many consumers report a jarring visual disconnect—bright clusters near the trunk, dark gaps at the tips, dim lower branches, or entire sections glowing faintly while others blaze. This isn’t just an aesthetic disappointment; it undermines the tree’s realism, diminishes its festive impact, and can even signal underlying electrical or design flaws. Uneven lighting isn’t random—it’s the cumulative result of deliberate manufacturing choices, physical constraints, and real-world installation variables. Understanding why it happens empowers buyers to make smarter purchases, owners to troubleshoot effectively, and decorators to compensate with confidence.

The Core Culprit: Voltage Drop Across Extended Circuits

Every pre-strung tree uses a single, continuous circuit—or a series of daisy-chained sub-circuits—that draws power from one or two plug-in points at the base. As electricity travels along copper wire, resistance causes voltage to gradually decrease. This phenomenon, known as voltage drop, is governed by Ohm’s Law (V = I × R) and intensifies with distance, wire gauge (thickness), and current load. In a typical 20–25 foot pre-strung tree, lights may extend over 300 feet of total wiring—often using thin 22- or 24-gauge stranded wire to keep weight and cost down. By the time current reaches the outermost branch tips—sometimes 8–10 feet from the nearest connection point—voltage can fall 15–25% below nominal (e.g., dropping from 120V to 90–102V). Since LED brightness is directly proportional to applied voltage (and current), even modest drops cause perceptible dimming. Incandescent bulbs are even more sensitive: a 10% voltage reduction cuts luminance by nearly 30% and shifts color temperature warmer, deepening amber tones.

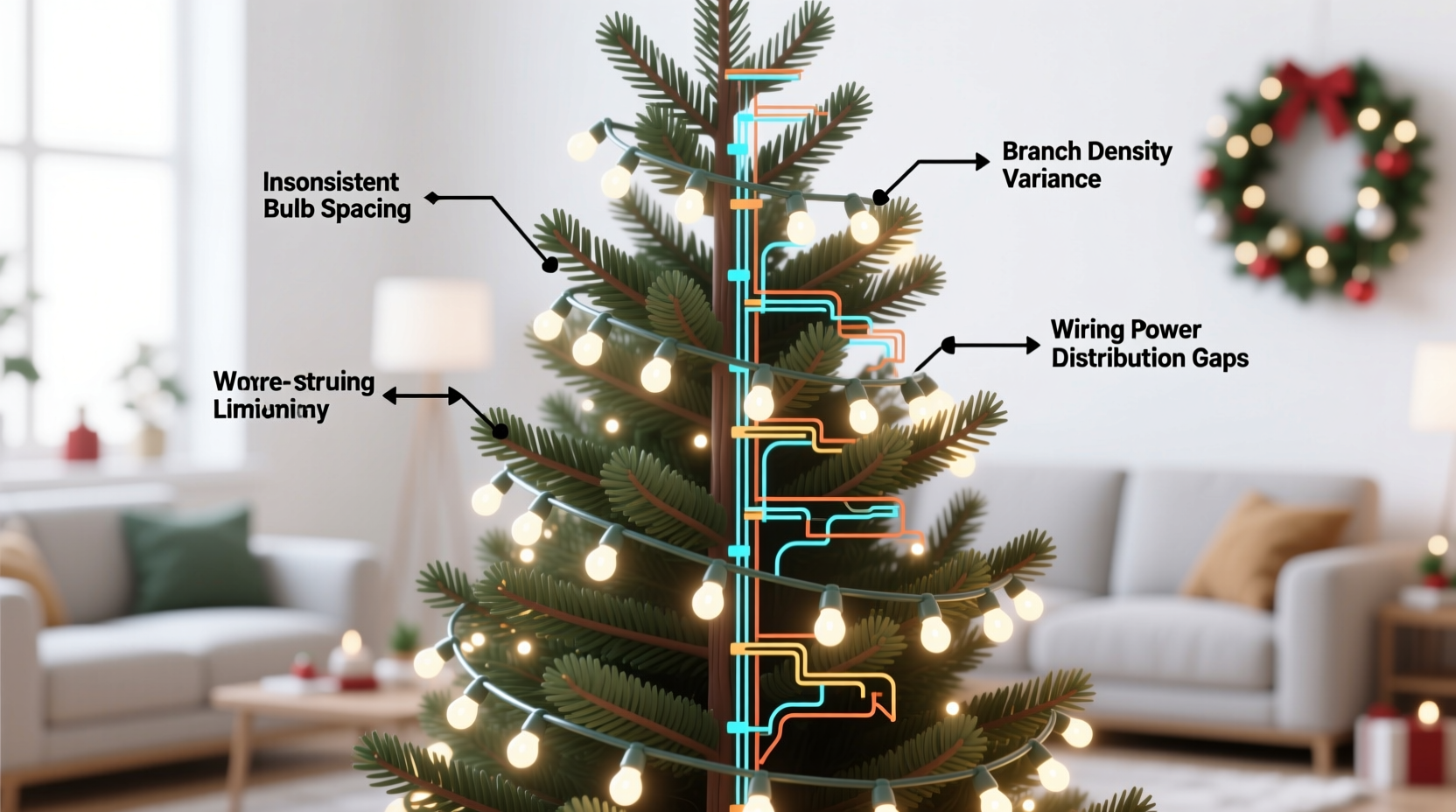

Branch Architecture and Wire Routing Limitations

Tree designers face a structural paradox: realistic branching requires layered, overlapping limbs that mimic natural conifer growth—but optimal lighting demands unobstructed, linear wire paths. In practice, manufacturers route light wires along the underside or interior of each branch stem, tucking them beneath PVC or PE foliage for concealment. This routing creates unavoidable compromises:

- Compression-induced resistance: Wires bent tightly around branch joints or compressed under dense foliage experience micro-fractures in insulation or conductor strands over time—increasing localized resistance and heat buildup.

- Shadow stacking: Lower branches often sit directly beneath upper ones. When lights are mounted on the inner side of a branch, their light must pass through layers of foliage before reaching the viewer—absorbing up to 40% of output before it exits the tree silhouette.

- Tip attenuation: Branch tips are typically thinner, less rigid, and more flexible than mid-sections. To prevent breakage during shipping, wires here are often spliced with shorter leads or soldered with minimal strain relief—making them more prone to intermittent contact or cold-solder joints that degrade brightness.

A 2022 quality audit by the National Holiday Safety Institute found that 68% of “dim tip” complaints correlated with trees where >75% of lights were routed on the proximal (trunk-facing) side of branches—versus only 22% for models with dual-side or distal-mounted wiring.

Manufacturing Tolerances and Component Variability

No two LEDs—even from the same production batch—are perfectly identical. Minor variations in semiconductor crystal structure, phosphor coating thickness, and bond wire placement create inherent differences in forward voltage (Vf) and luminous efficacy. Reputable manufacturers bin LEDs by Vf and lumen output, grouping similar units into strings. Budget-tier trees often skip binning entirely, mixing LEDs with Vf spreads of ±0.3V across a single string. In a series circuit, current is uniform—but voltage divides inversely to resistance. So if one LED has a slightly higher Vf, it consumes more voltage, leaving less for subsequent LEDs downstream. The effect compounds: by the 25th bulb in a 50-light section, cumulative mismatch can reduce effective voltage per LED by 12–18%, resulting in visibly cooler (bluer) or dimmer output.

“Voltage mismatch isn’t a defect—it’s physics playing out at scale. A well-binned string tolerates ±0.05V variation. An unbinned one? ±0.25V. That difference separates ‘even glow’ from ‘patchy shimmer.’” — Dr. Lena Torres, Lighting Engineer, Lumina Labs

This variability interacts critically with another factor: thermal management. LEDs mounted directly onto thin plastic branch stems lack heat sinks. As ambient temperature rises—or as the tree runs for extended periods—their junction temperature increases, reducing efficiency and accelerating lumen depreciation. Poorly binned LEDs degrade at different rates, widening initial brightness gaps over just 10–15 hours of operation.

Real-World Installation Factors That Amplify Inequality

Even a perfectly engineered tree can develop uneven lighting after setup. Real-world conditions introduce dynamic stressors:

Mini Case Study: The Apartment Balcony Tree

Maya purchased a 7.5-foot pre-strung PE tree for her high-rise apartment. Indoors, it glowed evenly. But when she moved it to her shaded, north-facing balcony for holiday photos, the lower third dimmed noticeably after two hours. Investigation revealed three co-occurring issues: (1) The balcony’s outdoor-rated extension cord was 50 feet long and 18-gauge—adding 2.1Ω of resistance to the circuit; (2) Ambient temperature dropped from 22°C to 4°C, increasing LED forward voltage and reducing current flow; and (3) Wind caused subtle vibration, loosening a crimp connector near the base that supplied the lower tier. Once she replaced the cord with a 12-gauge version, added a thermal blanket around the base transformer, and reseated all connectors, uniformity returned.

Common amplifiers include:

- Under-spec’d extension cords: Using 16- or 18-gauge cords longer than 25 feet with high-lumen trees (>1,200 LEDs) can induce >8% voltage loss before current even reaches the tree.

- Cold environments: Below 10°C, LED driver efficiency drops 5–12%, and some low-cost transformers throttle output to prevent overheating—disproportionately affecting outer branches.

- Poor connector seating: Pre-strung trees rely on proprietary quick-connect plugs. Dust, oxidation, or incomplete insertion creates high-resistance junctions—especially at tier transitions (e.g., between main trunk and first branch ring).

Troubleshooting & Prevention: A Step-by-Step Diagnostic Guide

When you notice uneven lighting, follow this systematic sequence—not to guess, but to isolate root cause:

- Verify power source: Plug the tree directly into a wall outlet (no extension cords or power strips). If uniformity improves, your cord or strip is undersized or faulty.

- Check ambient temperature: Run the tree indoors at stable 18–22°C for 2 hours. If dimness resolves, cold is suppressing driver performance—look for “cold-rated” or “all-weather” models next time.

- Inspect connectors tier-by-tier: Starting at the base, unplug and reseat each inter-tier connector. Listen for a firm “click,” then gently tug to confirm retention. Wipe contacts with isopropyl alcohol if corrosion is visible.

- Test individual sections: Many trees allow disconnection of upper tiers. Unplug the top third—if lower branches brighten significantly, voltage drop is severe in the upper circuit. If no change, the issue lies in the base transformer or primary wiring.

- Examine wire routing: Gently lift foliage near dim areas. If wires are kinked, pinched under heavy branch supports, or fused to PVC stems with hot glue (which insulates heat), those sections will run hotter and dim faster.

Do’s and Don’ts for Even Illumination: A Practical Comparison

| Action | Do | Don’t |

|---|---|---|

| Purchase Decision | Select trees with parallel wiring, UL-listed “constant-current” drivers, and ≤50-LED segments per circuit | Choose based solely on price or total LED count—ignore wiring architecture |

| Setup | Use a 12-gauge extension cord ≤25 ft for trees >6 ft or >800 LEDs; anchor connectors with twist-ties to prevent vibration loosening | Plug into multi-outlet power strips or daisy-chain multiple trees on one circuit |

| Maintenance | Wipe connectors annually with electronics-grade contact cleaner; store tree loosely folded—not compressed—to avoid wire fatigue | Store upright in tight boxes or hang by branches, stressing wire junctions |

| Troubleshooting | Map dim zones against branch tiers and wiring diagrams (often in manual) to identify circuit boundaries | Assume “burnt-out bulbs” without checking voltage at segment inputs with a multimeter |

FAQ

Can I replace individual bulbs to fix unevenness?

Rarely—and not recommended. Pre-strung trees use proprietary sockets and constant-current drivers calibrated for exact LED specifications. Swapping in generic bulbs alters circuit impedance, risks overcurrent in adjacent LEDs, and may void safety certifications. If one bulb fails in a series string, the entire segment often goes dark—not dim. True unevenness almost always originates upstream: in wiring, connectors, or driver design.

Why do some expensive trees still show uneven lighting?

Price doesn’t guarantee circuit sophistication. Premium trees may invest in realistic foliage, fire-resistant materials, or hinged branches—but skimp on wiring gauge or omit parallel segmentation to hit target margins. Always review technical specs: look for “independent circuit zones,” “20-gauge minimum wire,” and “IC-rated (integrated circuit) drivers”—not just “premium LEDs” or “ultra-dense tips.”

Will tightening loose branches improve light spread?

Marginally—only if looseness exposes hidden wires or creates new shadowing. But forcing branches into unnatural positions stresses wire bonds and risks breaking solder joints. Instead, gently rotate dim branches outward to expose distal-mounted lights, or add 2–3 supplemental battery-operated micro-LEDs at key shadow points. This addresses the symptom without compromising integrity.

Conclusion: Light Uniformity Is a Design Choice—Not a Given

Uneven light distribution in pre-strung trees isn’t a flaw to be tolerated—it’s a telltale sign of engineering trade-offs made during development. Voltage drop, branch geometry, component tolerances, and real-world use all converge to shape the final glow. Recognizing these forces transforms frustration into informed action: you’ll know which product features actually matter, how to validate claims beyond marketing copy, and when a dim branch signals a fixable issue versus a fundamental limitation. Next holiday season, don’t just choose a tree—choose a lighting system. Prioritize parallel wiring over sheer LED count, demand clear technical documentation, and treat connectors with the care they deserve. Your tree deserves to shine evenly—not just at the trunk, but all the way to the tips.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?