Resin 3D printing offers exceptional detail and surface finish, making it a favorite among hobbyists and professionals alike. However, one common frustration—especially for newcomers—is discovering that a freshly printed model feels sticky or tacky to the touch. This issue not only affects the final appearance but can also compromise durability and functionality. Understanding why this happens and how to fix it is essential for achieving consistently high-quality prints.

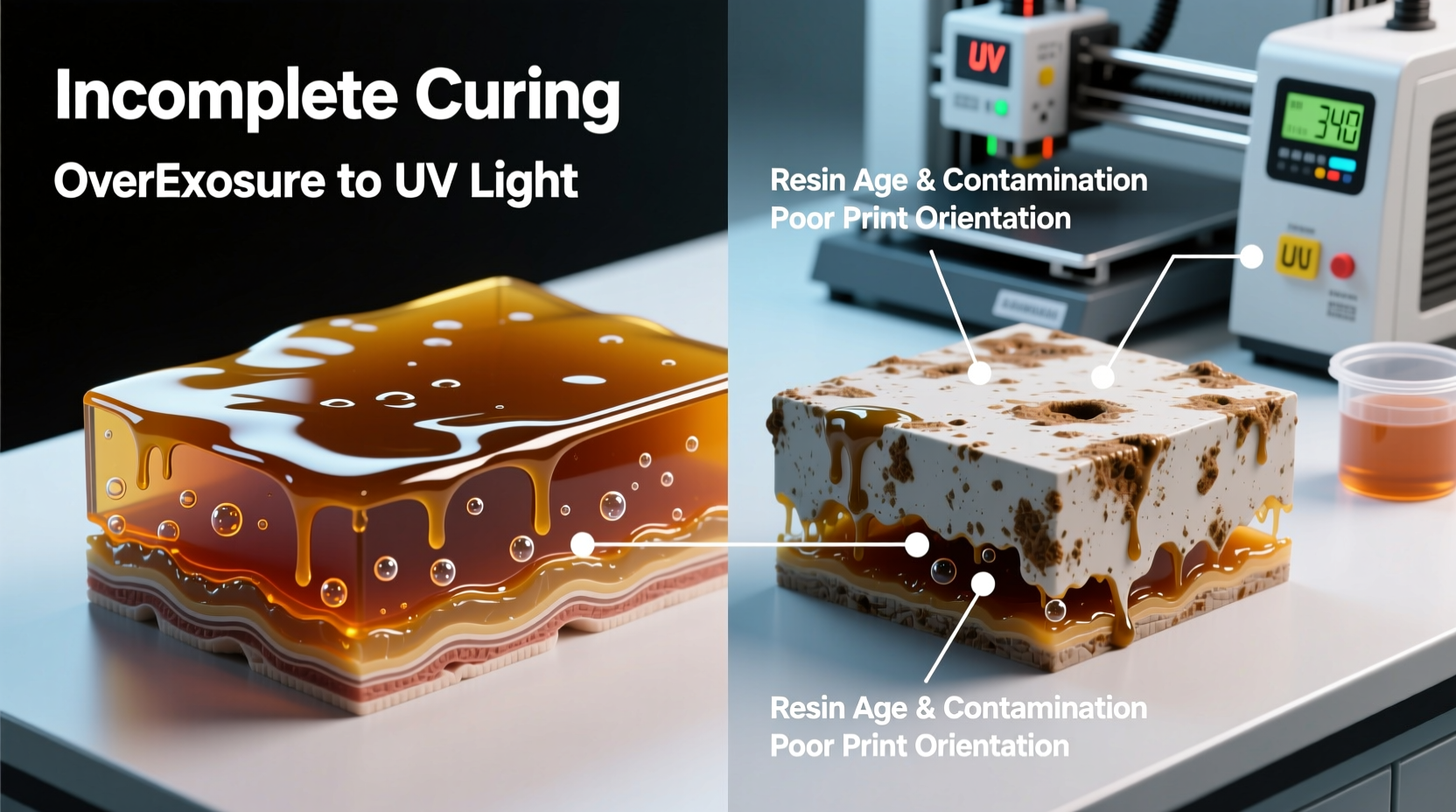

The stickiness in resin prints typically stems from incomplete curing—a process where liquid photopolymer resin solidifies under UV light. If any part of the resin remains uncured or partially cured, it retains a gummy texture. The root causes range from improper post-processing techniques to equipment limitations. Addressing these issues requires both knowledge and precision. Below, we break down the science behind sticky prints, explore the most common culprits, and provide actionable solutions to ensure full, reliable curing.

Understanding Resin Curing and Post-Curing

Unlike FDM printing, which extrudes molten plastic that cools into shape, resin printing relies on photopolymerization. During the print, a UV laser or projector selectively cures thin layers of liquid resin, building the object layer by layer. However, this initial curing is often incomplete. Resin manufacturers design their materials to cure just enough during printing to maintain shape without over-curing, which could cause adhesion issues or failed prints.

Post-curing—the step after washing and drying the print—is where full polymerization occurs. Exposing the print to intense, uniform UV light ensures that all remaining monomers cross-link into a solid structure. Skipping or inadequately performing this step leaves behind uncured resin, resulting in a sticky surface. It's important to note that even if a print looks solid, it may still be chemically unstable until fully post-cured.

“Post-curing isn’t optional—it’s a critical phase in the resin printing workflow. Without it, mechanical properties like strength and heat resistance won’t reach their potential.” — Dr. Lena Torres, Materials Scientist at Formlabs

Common Causes of Sticky Resin Prints

Several factors contribute to sticky prints, often interacting in ways that compound the problem. Identifying the specific cause in your setup is the first step toward resolution.

1. Inadequate Post-Curing Time or Intensity

Underexposure during post-curing is the leading reason for stickiness. Many users rely on sunlight or low-power UV lamps, which lack consistent intensity and spectrum. Sunlight varies in UV output based on time of day, weather, and geographic location. Similarly, cheap UV boxes may have weak bulbs or uneven light distribution, leaving shadowed areas under-cured.

2. Insufficient Washing After Printing

If residual uncured resin remains on the surface after cleaning, it can interfere with proper post-curing. Isopropyl alcohol (IPA) is standard for washing, but using diluted or contaminated IPA reduces effectiveness. Prints washed too briefly or in dirty solvent will retain a film of liquid resin that never fully hardens.

3. Poor Print Orientation or Trapped Resin

Complex geometries, especially those with deep cavities, overhangs, or narrow channels, can trap uncured resin. Even thorough washing might not remove all liquid from internal pockets. When exposed to UV light, the outer layer may cure while inner wet resin remains, creating a soft core or sticky patches.

4. Low-Quality or Degraded Resin

Old or improperly stored resin degrades over time. Exposure to ambient light or oxygen can initiate premature curing, altering viscosity and reactivity. Some third-party resins also have inconsistent formulations, leading to unpredictable curing behavior. Yellowed or cloudy resin should be discarded.

5. Incorrect Layer Exposure Settings

If individual layers during printing aren't sufficiently cured, the entire structure starts off weak. Under-exposed layers absorb more energy during post-cure, increasing the risk of incomplete hardening. These settings vary by printer model, resin type, and even vat condition (e.g., scratched PDMS film).

Curing Solutions: Best Practices for Non-Sticky Prints

Eliminating stickiness requires a systematic approach to both printing and post-processing. Implementing the following steps significantly improves curing outcomes.

Step-by-Step Guide to Proper Post-Curing

- Wash Thoroughly: Submerge the print in fresh IPA for 5–10 minutes, agitating gently. Use a soft brush to reach crevices. For large prints, consider an ultrasonic cleaner for deeper penetration.

- Dry Completely: Allow the print to air-dry for 15–30 minutes in a dust-free area. Moisture or residual solvent can block UV absorption.

- Rotate During Curing: Place the print on a turntable or rotate it manually every 2–3 minutes to ensure all sides receive equal exposure.

- Use Recommended Curing Times: Follow resin manufacturer guidelines. Typical times range from 2–10 minutes per side, depending on print size and UV intensity.

- Avoid Over-Curing: Excessive UV exposure can cause brittleness, yellowing, or warping. Stick to recommended durations unless testing for specific needs.

Recommended Equipment for Reliable Curing

Investing in proper tools makes a dramatic difference. A dedicated UV curing station with a rotating platform and adjustable timers delivers far better results than DIY setups.

| Equipment Type | Pros | Cons |

|---|---|---|

| Dedicated UV Curing Chamber | Uniform light, rotation, timer control, safety features | Higher cost ($100–$300) |

| UV LED Lamp (Handheld) | Affordable, portable, good for small fixes | Inconsistent coverage, no rotation, risk of overexposure |

| Sunlight (Outdoor) | Free, natural broad-spectrum UV | Unpredictable, slow, risk of warping due to heat |

| DIY UV Box with Fluorescent Tubes | Customizable, moderate cost | Potential hotspots, aging bulbs reduce output |

Mini Case Study: Fixing Persistent Stickiness in Miniature Models

Mark, a tabletop gaming enthusiast, regularly prints intricate miniatures using a popular gray engineering resin. Despite careful printing, he noticed that fine details on helmets and cloaks remained tacky even after 10 minutes of UV exposure. Initial attempts with a handheld lamp worsened the issue—some areas turned brittle while others stayed sticky.

After reviewing his process, Mark realized two key oversights: he was using 70% isopropyl alcohol left over from electronics cleaning, and he wasn’t rotating the models during curing. He upgraded to 99% IPA, added an ultrasonic bath for washing, and purchased a UV curing chamber with a turntable. By adjusting post-cure time to 6 minutes per side and ensuring complete drying, his prints achieved full hardness without detail loss.

This case illustrates how seemingly minor lapses—like solvent quality and static curing—can derail results, especially with detailed prints where surface integrity matters most.

Checklist: Ensuring Fully Cured, Non-Sticky Prints

- ✅ Use IPA with at least 90% alcohol concentration for washing

- ✅ Wash prints for 5–10 minutes with agitation or ultrasonic assistance

- ✅ Dry prints completely before post-curing (no visible droplets or sheen)

- ✅ Verify resin expiration date and storage conditions (cool, dark, sealed)

- ✅ Confirm correct exposure settings in slicing software for your resin type

- ✅ Use a UV curing station with rotation for even exposure

- ✅ Follow manufacturer-recommended curing times per side

- ✅ Inspect prints after curing—press a fingernail gently; no indentation should remain

- ✅ Store finished prints away from direct sunlight to prevent long-term degradation

Frequently Asked Questions

Can I over-cure a resin print?

Yes. Excessive UV exposure leads to embrittlement, discoloration (yellowing), and micro-cracking. While some applications benefit from extended curing for maximum strength, most standard prints should adhere to manufacturer guidelines to avoid material fatigue.

Why does my print feel dry but still leave residue on my fingers?

This indicates a partially cured surface layer sitting atop uncured resin beneath. It often occurs when prints are removed from the wash too early or when trapped resin seeps out after drying. Re-washing and extending post-cure time usually resolves this.

Is there a way to test if my UV curing unit is still effective?

Yes. Use a UV intensity meter (available affordably online) to measure output. Alternatively, perform a comparative test: cure identical small prints for the same duration—one in your current unit, one in a known-good setup. Compare surface hardness and tackiness. A noticeable difference suggests bulb aging or power issues.

Expert Tips for Long-Term Success

Storage plays a crucial role in resin performance. Keep bottles tightly sealed in their original opaque containers, stored upright in a cool, dark cabinet. Avoid temperature fluctuations, as condensation inside the bottle introduces moisture, affecting cure response.

Additionally, monitor your printer’s condition. A degraded FEP film or contaminated build plate can affect first-layer adhesion and initial curing, setting off a chain reaction of poor layer bonding and incomplete polymerization. Replace consumables according to usage—typically every 20–50 prints, depending on wear.

“Printing success isn’t just about the machine—it’s about managing the entire ecosystem: resin, environment, cleaning, and curing. Treat each step with equal importance.” — James Reed, 3D Printing Lab Manager at MIT Hobbyist Innovation Group

Conclusion: Achieve Flawless Results with Consistent Process Control

A sticky resin print doesn’t mean failure—it’s a signal that one or more steps in your workflow need refinement. From washing technique to UV exposure, each stage influences the final cure. By diagnosing the root cause and applying targeted solutions, you can consistently produce prints that are not only visually stunning but also mechanically sound.

Start by auditing your current process: check your IPA freshness, verify curing times, and inspect your equipment. Small adjustments often yield dramatic improvements. As you gain confidence, experiment with advanced techniques like nitrogen-inerted curing or dual-wavelength systems for specialized resins.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?