3 Phase Forward Reverse Control Circuit

1/2

1/2

1/2

1/2

About 3 phase forward reverse control circuit

Where to Find 3 Phase Forward Reverse Control Circuit Suppliers?

China leads global production of industrial control components, with key manufacturing clusters concentrated in Zhejiang and Guangdong provinces. Zhejiang excels in electromechanical switch systems, hosting specialized suppliers of rotary cam switches and selector-based control circuits. The region benefits from mature supply chains for copper alloys, insulating plastics, and precision-machined contacts, enabling cost reductions of 15–25% compared to Western equivalents. Guangdong, particularly Shenzhen, dominates electronic motor control modules, leveraging proximity to semiconductor foundries and surface-mount technology (SMT) assembly lines.

These industrial ecosystems support rapid prototyping and scalable production, with many facilities offering integrated design, PCB fabrication, and functional testing under one roof. Suppliers typically maintain lead times of 7–15 days for standard units, supported by localized component sourcing and automated production lines. Buyers gain access to flexible MOQs—often as low as 1–5 pieces—and customization options for voltage ratings, mounting configurations, and indicator integration. Export infrastructure is well-developed, with most manufacturers experienced in international compliance and drop-shipping logistics.

How to Choose 3 Phase Forward Reverse Control Circuit Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify that products align with applicable IEC standards for industrial switching equipment (e.g., IEC 60947-5-1). For export markets, CE or CCC certification should be documented. Electronic controllers must demonstrate EMC and RoHS compliance, especially when incorporating PWM or MOSFET driver circuits. Request test reports for dielectric strength, contact resistance, and thermal performance under load.

Production Capability Assessment

Evaluate core competencies based on facility scope and product range:

- Suppliers specializing in mechanical cam switches typically offer robust housings (thermoset or engineering-grade plastic) and silver alloy contacts rated up to 250A

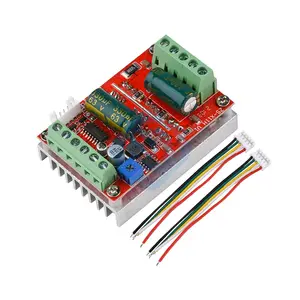

- Electronic control module producers should have SMT lines, in-circuit testing (ICT), and firmware programming capabilities for BLDC or DC motor drivers

- Cross-reference online revenue indicators and reorder rates to assess market validation and customer retention

Transaction Safeguards

Prioritize suppliers with verifiable response times ≤5 hours and 100% on-time delivery records. Use secure payment mechanisms such as escrow services to mitigate risk during initial transactions. Conduct sample testing for mechanical endurance (minimum 10,000 cycles for rotary switches) and electrical reliability under phase reversal conditions. Confirm packaging suitability for international shipping to prevent terminal damage.

What Are the Best 3 Phase Forward Reverse Control Circuit Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Zhejiang Jiushi Electronics Co., Ltd. | Rotary Switches, Push Button Switches, Indicator Lights | $2.70–$5.60 | 5 pieces | 100% | ≤5h | 16% | $10,000+ |

| Shenzhen Co-Etech Limited | BLDC Controllers, Power Driver Modules, ICs | $5.80–$17.00 | 1 piece | 100% | ≤3h | <15% | $30,000+ |

| Shenzhen Yuzens Technologies Co. Ltd. | Motor Speed Controllers, Electronic Modules, Relays | $1.69–$13.00 | 1–5 pieces | 100% | ≤4h | <15% | $60,000+ |

| Zhejiang Yaming Electric Co., Ltd. | Rotary Cam Switches, Terminal Blocks, Rocker Switches | $2.20–$85.00 | 1–5 pieces | 100% | ≤7h | 33% | $30,000+ |

| Shenzhen Chuangyida Electronics Co., Limited | DC Motor Controllers, Thyristor Modules, Power Supplies | $0.73–$29.00 | 3–10 pieces | 100% | ≤7h | 20% | $130,000+ |

Performance Analysis

Zhejiang-based suppliers like Jiushi and Yaming focus on electromechanical switching solutions, offering durable cam switches suitable for direct three-phase motor reversal. Their pricing reflects economies of scale in stamped metal components and molded housings. In contrast, Shenzhen suppliers—Co-Etech, Yuzens, and Chuangyida—specialize in solid-state control circuits, providing compact electronic modules for brushless and DC motors with forward-reverse logic. These firms exhibit higher technical flexibility, supporting wide input voltages (6V–60V) and programmable speed profiles. Chuangyida stands out with the highest reported online revenue ($130,000+), indicating strong export volume, while Yaming achieves the highest reorder rate (33%), suggesting consistent quality and service satisfaction. Buyers seeking rugged mechanical selectors should prioritize Zhejiang manufacturers; those requiring compact, electronically driven solutions will benefit from Shenzhen’s electronics ecosystem.

FAQs

How to verify 3 phase forward reverse control circuit supplier reliability?

Confirm certifications through official databases and request product test reports. Analyze supplier metrics including on-time delivery rate, response time, and reorder frequency. Conduct factory audits via video tour to validate production processes and quality control checkpoints.

What is the typical sampling timeline?

Standard samples are shipped within 3–7 days. Customized versions requiring PCB reconfiguration or firmware adjustments may take 10–14 days. Add 5–10 days for international express delivery.

Can suppliers provide customized control circuits?

Yes, most suppliers support modifications including voltage rating adjustments, enclosure material changes, LED indicators, and wiring configurations. Electronic controllers can often be reprogrammed for specific acceleration/deceleration curves or protection thresholds.

What are common MOQ and pricing structures?

MOQs range from 1 piece (electronic modules) to 5 pieces (mechanical switches). Unit prices decrease significantly at volumes above 100 units. High-current cam switches (e.g., 250A) command premium pricing due to material costs and structural reinforcement.

How to ensure compatibility with existing motor systems?

Provide technical specifications including motor type (AC induction, BLDC, DC), voltage, current rating, and control signal requirements. Reputable suppliers will confirm interface compatibility and isolation requirements before production.