3d Printing Is Used To Produce Complex Tools And Components

About 3d printing is used to produce complex tools and components

Where to Find Suppliers for 3D Printing of Complex Tools and Components?

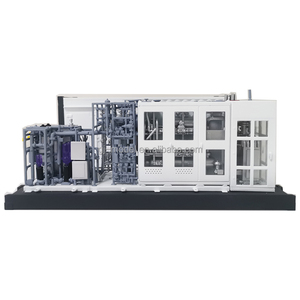

China has emerged as a leading hub for industrial 3D printing services, particularly in the production of complex tools and components requiring high precision and material integrity. Key manufacturing clusters are concentrated in Zhejiang, Fujian, and Guangdong provinces, where specialized suppliers leverage advanced metal additive technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These regions benefit from established ecosystems integrating design engineering, rapid prototyping, and post-processing capabilities—including CNC finishing, heat treatment, and surface coating—enabling end-to-end production within tightly controlled timelines.

Suppliers in these zones operate scalable facilities equipped with multi-laser systems capable of processing high-performance alloys like Inconel, titanium, stainless steel, and aluminum. The integration of digital workflow platforms allows for seamless transition from CAD models to final parts, supporting low-volume batch runs and customized tooling solutions. Buyers gain access to competitive pricing structures, with average unit costs starting below $1.00 for small components, and lead times typically ranging from 7–15 days for standard orders. Localized supply chains reduce overhead by up to 25% compared to Western-based providers, while maintaining compliance with international quality expectations through documented process controls.

How to Choose 3D Printing Suppliers for Complex Components?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

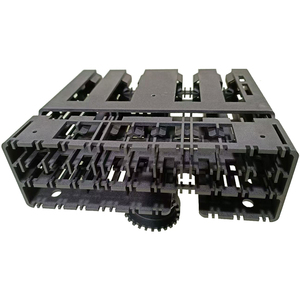

Production and Technical Capability

Assess whether the supplier operates certified additive manufacturing systems (e.g., EOS, SLM Solutions, or HP Multi Jet Fusion) and maintains in-house design validation tools such as finite element analysis (FEA) and topology optimization software. Look for evidence of metrology infrastructure, including coordinate measuring machines (CMM) and CT scanning, to verify dimensional accuracy down to ±0.05 mm. Prioritize vendors offering multiple post-processing options—such as stress relieving, hot isostatic pressing (HIP), and surface polishing—to ensure mechanical performance meets application requirements.

Quality Management and Compliance

While formal ISO 9001 certification may not be explicitly listed in all cases, consistent on-time delivery rates above 95% and documented quality inspection reports indicate robust internal systems. For aerospace, medical, or automotive applications, request material test certificates (MTCs), build logs, and traceability documentation per lot. Although CE or RoHS declarations are less common among service bureaus, their absence should prompt additional due diligence if exporting to regulated markets.

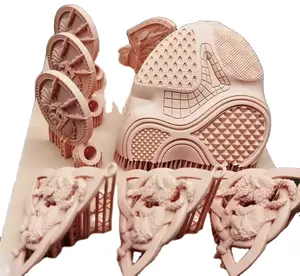

Customization and Scalability Verification

Evaluate customization depth beyond basic geometry replication. Leading suppliers support full parameter control over layer thickness (down to 20μm), infill density, orientation, and support structure design. Confirm availability of multi-material printing, color rendering, and functional assembly integration. Cross-reference online revenue data and reorder rates—suppliers with reorder rates exceeding 40% demonstrate customer retention driven by consistency and responsiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms that align with order milestones, especially for first-time engagements. Require sample prototypes before full production runs to validate surface finish, fit, and function. Analyze response time metrics; suppliers consistently replying within ≤2 hours are more likely to maintain proactive communication throughout the project lifecycle.

What Are the Top 3D Printing Suppliers for Complex Tools and Components?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response Time | Min. Order | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Anqing Wayne Hand Model Technology Co., Ltd. | Machining Services (1,407); Sheet Metal Fabrication (166) | US $240,000+ | 92% | 47% | ≤2h | 1 piece | $4.70 | Limited (implied via product range) |

| Zhejiang Yunjiang High Tech Co., Ltd. | Custom 3D Printing, Multi-color PLA, Metal Parts | US $70,000+ | 100% | 39% | ≤2h | 1 piece | $0.39–7.90 | Color, material, size, logo, packaging, graphic |

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Machining Services (180); Casting Services (36) | US $30,000+ | 100% | 28% | ≤4h | 1 piece | $0.90–99.90 | Material, strength, resolution, structure complexity |

| Xiamen Sanzhu Sporting Goods Co., Ltd. | Metal 3D Printing (SLM/DMLS), Mold Design | US $2,000+ | 100% | 100% | ≤5h | 1 gram / 1 piece | $0.90–10.00 | Food-grade, aerospace, cross-industry applications |

| Guangzhou Gaojie Model Design And Manufacturing Co., Ltd. | CNC Machining, Plastic Models, 3D Scanning | US $80,000+ | 96% | 48% | ≤4h | 1 piece | $0.25–2.90 | Engraving, painting, material selection, mold making, size modification |

Performance Analysis

Zhejiang Yunjiang High Tech and HUITONG RAPID PROTOTYPE stand out for balancing high on-time delivery (100%) with broad customization capabilities and competitive pricing. Anqing Wayne Hand Model Technology demonstrates strong market presence with the highest reported online revenue, suggesting scalability and sustained demand. Xiamen Sanzhu, despite lower revenue volume, achieves a perfect 100% reorder rate, indicating exceptional satisfaction in niche applications such as food-grade or aerospace tooling. Guangzhou Gaojie offers the lowest price point ($0.25/unit) and extensive surface and material customization, making it ideal for detailed models and architectural components. Buyers seeking high-volume metal part production should prioritize suppliers with dedicated SLM/DMLS infrastructure and proven experience in high-strength alloy processing.

FAQs

What materials are commonly used in industrial 3D printing for complex tools?

Stainless steel (316L, 17-4 PH), titanium (Ti6Al4V), Inconel 718, aluminum (AlSi10Mg), and tool steels (H13, maraging steel) are standard for metal printing. For non-metallic components, PA12 (nylon), ABS, PC, PETG, and resin-based photopolymers dominate functional prototyping and jigs/fixtures production.

What is the typical minimum order quantity (MOQ) for 3D printed components?

Most suppliers offer MOQs of 1 piece, enabling cost-effective prototyping and small-batch production. Pricing is often volume-tiered, with discounts applied at 10+ and 100+ unit thresholds.

How long does it take to receive custom 3D printed parts?

Standard lead time ranges from 7 to 15 days, including printing, post-processing, and quality checks. Express services may reduce this to 3–5 days at a premium. Add 5–10 days for international shipping depending on destination and method.

Can suppliers provide design for additive manufacturing (DFAM) support?

Yes, many suppliers offer free design reviews to optimize part orientation, minimize supports, reduce weight, and enhance printability. Advanced vendors use simulation tools to predict thermal distortion and suggest geometric modifications.

Are samples available before placing bulk orders?

Sample production is standard practice. Most suppliers will produce a single prototype for approval, often at partial or full cost recovery. This step is critical for validating tolerances, surface finish, and assembly compatibility.