5 Axis Cnc Lathe Producer

CN

CN

About 5 axis cnc lathe producer

Where to Find 5 Axis CNC Lathe Producers?

China remains the dominant hub for 5-axis CNC lathe manufacturing, with key production clusters concentrated in Shaanxi, Shandong, and Jiangsu provinces. These regions host vertically integrated facilities that combine casting, precision machining, and final assembly under one roof, enabling streamlined production cycles and cost efficiency. The presence of mature industrial ecosystems—supported by local steel suppliers, component manufacturers, and technical labor pools—allows producers to maintain competitive pricing while meeting international quality benchmarks.

Suppliers in these zones typically operate dedicated production lines for multi-axis CNC equipment, leveraging automation and modular design principles to reduce lead times. Buyers benefit from proximity to supporting infrastructure, including rail-linked logistics hubs and export-oriented trade zones. Average production lead times range from 30 to 60 days depending on customization level, with many manufacturers offering just-in-time delivery models for repeat orders. Localized supply chains contribute to a 15–25% cost advantage over equivalent machinery produced in Europe or North America.

How to Choose 5 Axis CNC Lathe Producers?

Selecting a reliable producer requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Quality Assurance

Confirm adherence to recognized quality management systems such as ISO 9001. While not all suppliers list certifications explicitly, consistent on-time delivery (≥97%) and documented testing procedures for spindle accuracy, axis alignment, and thermal stability are strong proxies for process control. For export markets, CE marking is often required for customs clearance and end-user compliance.

Production Infrastructure Assessment

Evaluate core operational metrics:

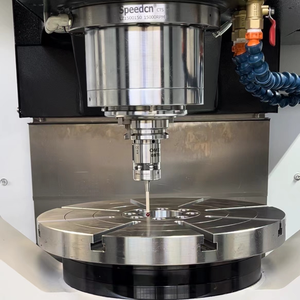

- Ownership of in-house production lines (cast iron bed manufacturing, linear guide integration, servo motor calibration)

- Minimum factory area exceeding 3,000m² to support full-cycle manufacturing

- Inclusion of R&D teams focused on motion control algorithms and tool path optimization

- Capacity for customization—including live tooling, Y-axis milling, C-axis contouring, and automated loading systems

Cross-reference product listings with response time and reorder rate data: suppliers maintaining ≤2-hour response times and reorder rates above 50% demonstrate higher customer satisfaction and service reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to ensure funds are released only after inspection and acceptance. Request detailed machine specifications—including control system type (e.g., Fanuc, Siemens, Mitsubishi), ball screw precision class, and rotary table resolution—before order confirmation. Pre-shipment inspections via third-party auditors or video walk-throughs can verify build quality and configuration accuracy.

What Are the Leading 5 Axis CNC Lathe Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shaanxi Jingwei Hongbo Cnc Equipment Co., Ltd. | Shaanxi, CN | Machining Centre, CNC Milling Machines | US $100+ | 100% | ≤1h | <15% | $19,998–48,500 | Limited |

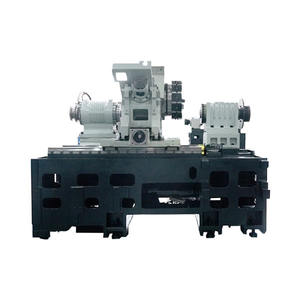

| Shandong HR Machinery Co., Ltd. | Shandong, CN | Swiss-type CNC Lathes, Multifunctional Turning Centers | US $250,000+ | 100% | ≤2h | 50% | $43,000–68,700 | Extensive (turrets, feeders, collets, labeling) |

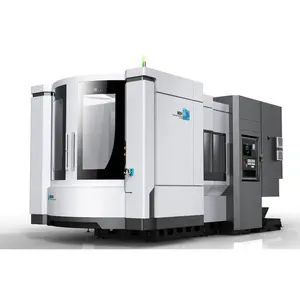

| Wuxi Weifu International Trade Co., Ltd. | Jiangsu, CN | Heavy-Duty 5-Axis CNC Turning Centers | - | 100% | ≤4h | - | $83,300–90,970 | Material, color, size, logo, packaging |

| Taizhou Luqiao Shiheng Cnc Lathe Co., Ltd. | Zhejiang, CN | CNC Lathe, Machining Centre | - | 100% | ≤1h | - | $19,000–35,000 | Limited |

| Shandong Handemo Technology Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Milling Machines | US $20,000+ | - | ≤12h | <15% | $13,666–120,000 | Model-dependent |

Performance Analysis

Shandong HR Machinery stands out with the highest online revenue (US $250,000+) and a 50% reorder rate, indicating strong market acceptance and robust customization capabilities. Their Swiss-type lathes target high-precision sectors such as medical device and aerospace components. In contrast, Wuxi Weifu offers premium-tier machines priced above $83,000, suggesting focus on heavy-duty industrial applications requiring enhanced rigidity and durability.

Shaanxi Jingwei Hongbo and Taizhou Luqiao Shiheng provide entry-level to mid-range solutions starting below $20,000, suitable for small workshops or budget-conscious buyers. However, limited customization options and lower reorder rates suggest less emphasis on long-term client retention. Shandong Handemo displays wide price dispersion ($13,666–$120,000), reflecting diverse product segmentation—from compact 5-axis mills to large-scale turning centers—though slower response times may impact buyer experience.

FAQs

How to verify 5 axis CNC lathe producer credibility?

Validate ownership of in-house production through facility videos or virtual audits. Check consistency between listed products and actual machine specifications. Analyze transaction patterns: sustained on-time delivery records (ideally 100%) and short response times (<4 hours) correlate with operational reliability.

What is the typical minimum order quantity (MOQ)?

Most producers set MOQ at 1 unit, allowing buyers to procure individual machines for testing or low-volume operations. This flexibility supports pilot runs and integration trials without large capital commitments.

Are customization options available for 5-axis CNC lathes?

Yes, particularly among mid-to-high-end producers. Common customizations include power turrets, Y-axis milling capability, live tooling, bar feeders, part catchers, control system selection, and branding elements like color schemes and logos. Shandong HR Machinery explicitly lists over ten configurable parameters, indicating advanced configurability.

What materials are commonly used in 5-axis CNC lathe construction?

Beds are typically cast from Meehanite or high-damping cast iron to minimize vibration. Linear guides and ball screws are sourced from brands like HIWIN, TBI, or THK for precision motion control. Spindles use high-speed angular contact bearings, with some models featuring ceramic hybrid options for extended service life.

How to assess post-purchase support?

Inquire about warranty terms (typically 12 months), availability of spare parts, and technical assistance channels. Preferred suppliers offer remote diagnostics, English-language manuals, and training resources. A high reorder rate often reflects satisfactory after-sales service and machine uptime performance.