5 Axis Cnc Milling Machine China

Top sponsor listing

Top sponsor listing

About 5 axis cnc milling machine china

Where to Find 5-Axis CNC Milling Machine Suppliers in China?

China remains the global epicenter for 5-axis CNC milling machine production, with concentrated manufacturing hubs in Shandong, Guangdong, and Jiangsu provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, advanced automation, and cost-efficient logistics. Shandong alone accounts for over 40% of China’s CNC router and machining center exports, supported by mature supply chains for ball screws, servo motors, and spindle systems. Dongguan and Suzhou serve as high-precision machining clusters, offering tight-tolerance capabilities (±0.005mm) critical for aerospace and medical applications.

Suppliers benefit from localized component sourcing—reducing lead times by 25–35% compared to offshore manufacturers—and access to skilled technical labor pools. The integration of R&D centers within factory complexes enables rapid prototyping and customization cycles, typically 10–14 days for modified configurations. Buyers gain flexibility in order scale, with standard lead times ranging from 30 to 60 days depending on complexity and configuration. Economies of scale allow Chinese suppliers to offer competitive pricing, often 20–40% below European or North American equivalents, without compromising core performance metrics.

How to Choose 5-Axis CNC Milling Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

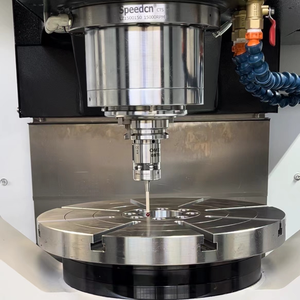

Confirm machine specifications align with application requirements: work envelope dimensions, spindle speed (typically 8,000–24,000 RPM), tool changer type (ATC standard), and control system compatibility (e.g., Syntec, Fanuc). For high-precision sectors like mold making or turbine blade manufacturing, demand evidence of laser interferometer calibration and thermal compensation systems. ISO 9001 certification should be considered baseline; CE marking is essential for compliance in EU markets.

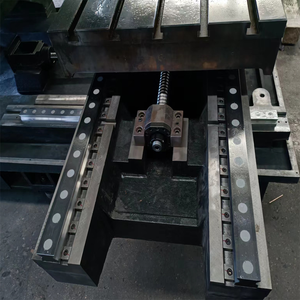

Production Infrastructure Assessment

Evaluate supplier capacity through verifiable indicators:

- Facility size exceeding 3,000m² indicating scalable operations

- In-house machining and assembly lines (not just final integration)

- Dedicated quality inspection stations with CMM and surface roughness testers

Cross-reference online revenue data and product listing volume as proxies for market activity. Prioritize suppliers with ≥94% on-time delivery rates and sub-2-hour response times to ensure responsiveness during commissioning and troubleshooting phases.

Customization & Support Readiness

Assess ability to accommodate non-standard requests: material-specific tooling (aluminum, PEEK, composites), custom programming, or hybrid processing (milling + drilling + tapping). Verify packaging standards for international shipping and availability of installation support or remote diagnostics. Reorder rate above 35% suggests customer satisfaction with both product reliability and after-sales service.

What Are the Top 5-Axis CNC Milling Machine Suppliers in China?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Scope | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Dongguan Thriving Metal Parts Co., Ltd. | Sheet Metal Fabrication (3047), Machining Services (825) | 94% | ≤2h | 37% | $470,000+ | Material, logo, drawing, anodize, packaging | N/A (service-focused) |

| Jinan Spower Machinery Technology Co., Ltd. | Machining Centre, CNC Milling Machines | 100% | ≤1h | 58% | $230,000+ | Spindle type, safety system, ATC, heavy-duty body | $16,899–78,000 |

| Shandong Chencan Machinery Incorporated Company | Wood Routers (256), Machining Centre (80) | 100% | ≤1h | 50% | $190,000+ | Foam, fiberglass, EPS, PU materials | $80,000–980,000 |

| Jinan Suntec Cnc Machinery Co., Ltd. | Wood Routers (201), CNC Milling Machines (18) | 100% | ≤2h | 50% | $80,000+ | Multi-head, foam, aluminum profiles | $15,000–75,000 |

| Jiangsu Sailing Intelligent Equipment Co., Ltd. | EDM Machines (381), Machining Centre (24) | 100% | ≤5h | 20% | $80,000+ | Vertical machining center configurations | $38,700–40,900 |

Performance Analysis

Jinan Spower stands out with the highest reorder rate (58%) and fastest response time (≤1h), suggesting strong post-sale support and customer retention. Shandong Chencan offers the broadest high-end capability, supporting specialized materials like fiberglass and EPS at six-figure price points, ideal for prototyping and composite part production. Jiangsu Sailing provides consistent mid-range vertical machining centers at fixed pricing, suitable for buyers prioritizing predictability over customization. Dongguan Thriving focuses on downstream services rather than standalone machines, positioning it as a partner for integrated component manufacturing. Response time variability—from ≤1h to ≤5h—highlights the importance of real-time communication readiness, particularly for urgent technical coordination.

FAQs

How to verify 5-axis CNC machine supplier credibility?

Cross-check ISO and CE certifications with issuing bodies. Request factory audit reports or video tours confirming in-house production. Analyze transaction history, focusing on on-time delivery consistency and dispute resolution records. Third-party inspection services can validate machine performance prior to shipment.

What is the typical lead time for 5-axis CNC machines?

Standard configurations require 30–45 days post-deposit. Customized models involving spindle upgrades or control system changes may extend to 60 days. Express production options are occasionally available for premium fees.

Do suppliers support global shipping and installation?

Yes, most established exporters offer CIF/FOB terms and coordinate sea freight logistics. Some provide optional technician dispatch for on-site commissioning, though associated travel costs are typically borne by the buyer.

Are samples or test runs possible before purchase?

Full-machine sampling is uncommon due to cost, but suppliers often provide machining videos, dimensional reports, or small-part test runs using customer-provided CAD files. Remote live demonstrations via video call are standard practice.

What customization options are commonly available?

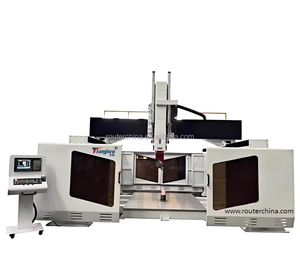

Buyers can specify spindle type (servo vs. frequency-controlled), tool changer configuration (ATC capacity), worktable size, and control software interface. Additional options include mist cooling systems, CCD alignment cameras, and safety enclosures. Material-specific tuning (e.g., for brass, PEEK, or carbon fiber) is frequently offered upon request.