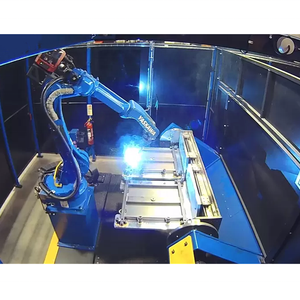

6 Axis Yaskawa Robot Customized

1/3

1/3

CN

CN

CN

CN

CN

CN

1/5

1/5

1/33

1/33

1/3

1/3

1/24

1/24

1/3

1/3

1/11

1/11

1/15

1/15

1/28

1/28

1/7

1/7

1/3

1/3

1/3

1/3

CN

CN

1/9

1/9

1/3

1/3

About 6 axis yaskawa robot customized

Where to Find 6 Axis Yaskawa Robot Customized Suppliers?

China remains the central hub for industrial robotics integration and customization, with key supplier clusters concentrated in Shanghai and Shandong province. These regions host specialized automation firms offering engineered solutions around premium robotic platforms such as Yaskawa’s 6-axis articulated robots. Shanghai serves as a technological nexus, combining advanced R&D infrastructure with proximity to international logistics networks, enabling rapid deployment of customized robotic systems across Asia, Europe, and North America.

The ecosystem supports both direct integration and value-added modifications—including end-of-arm tooling, control panel programming, linear seventh-axis tracks, and application-specific software configurations. Suppliers leverage vertically integrated workshops equipped with CNC machining, welding, and electrical assembly lines to deliver turnkey automation cells. Buyers benefit from localized supply chains that reduce component lead times by 20–35% compared to OEM-direct procurement, while maintaining compatibility with Yaskawa’s original performance specifications.

How to Choose 6 Axis Yaskawa Robot Customized Suppliers?

Selecting qualified partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Integration Expertise

Confirm supplier experience with Yaskawa robot series (e.g., GP, AR, MOTOMAN) through documented project portfolios. Verify capabilities in reprogramming, path optimization, and integration with peripheral equipment such as welding torches, conveyors, or vision systems. For safety-critical applications, demand compliance with ISO 10218-1 (industrial robot safety) and IEC 61508 (functional safety). CE marking is essential for European market deployment.

Customization Capacity

Assess scope of modifiable parameters:

- Robot reach, payload, and mounting configuration adjustments

- Color, labeling, and protective coating options

- Software customization: HMI interfaces, PLC integration, IoT connectivity

- Add-on components: dress packs, explosion-proof enclosures, linear tracks

Suppliers advertising "customization services" should provide engineering consultation and post-modification validation testing.

Production & Quality Assurance Verification

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification may not always be listed, consistent on-time delivery rates (≥97%) and sub-10-hour response times indicate operational discipline. Evaluate online transaction history where available—particularly order fulfillment consistency and customer feedback on post-sale support.

What Are the Best 6 Axis Yaskawa Robot Customized Suppliers?

| Company Name | Location | Verification Status | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shanghai Jiesheng Robot Co., Ltd. | Shanghai, CN | - | Articulated Robots, Welding Equipment, Manipulators | 100.0% | ≤7h | - | Not specified | $17,000–65,000 |

| Shanghai JSR Automation Co., Ltd | Shanghai, CN | Custom Manufacturer | Industrial Robots, Linear Tracks, CNC Loaders | 100.0% | ≤9h | <15% | Color, material, size, logo, packaging, graphics | $4,000–28,000 |

| Shandong Chenxuan Robot Technology Co., Ltd. | Shandong, CN | Custom Manufacturer | Handling & Welding Robots, Multifunctional Arms | 100.0% | ≤1h | - | Color, material, size, logo, packaging, graphics | $1,899–20,715 |

| Gongboshi Robot Technology Co., Ltd. | Shanghai, CN | Multispecialty Supplier | Programming Systems, Robotic Arms, Inspection Units | 100.0% | ≤3h | <15% | Color, material, size, logo, packaging, graphics | $19,654–69,000 |

| Xiangjing (Shanghai) Mechanical And Electrical Tech Co., Ltd. | Shanghai, CN | Multispecialty Supplier | GP Series Robots, Dress Packs, Control Panels | 100.0% | ≤7h | 25% | Programmable functions, grippers, protective covers, software compatibility, robot tracks | $15,000–68,000 |

Performance Analysis

All five suppliers demonstrate 100% on-time delivery performance, indicating strong logistical execution. Shandong Chenxuan stands out for responsiveness (≤1 hour), making it ideal for time-sensitive technical inquiries. Xiangjing (Shanghai) offers the most extensive customization breadth, including functional upgrades like programmable controls and seventh-axis integration. Price dispersion reflects application specialization—lower-priced units (<$5,000) likely represent partial assemblies or refurbished components, while systems exceeding $60,000 align with fully integrated, high-payload GP180/GP25 configurations. Reorder rate data suggests moderate customer retention, with only one supplier reporting above 20%, highlighting the project-based nature of robotic system sourcing.

FAQs

How to verify 6 axis Yaskawa robot customized supplier reliability?

Cross-check technical claims with product documentation and request evidence of prior installations. Conduct virtual factory audits to observe assembly processes and quality checkpoints. Validate warranty terms and availability of after-sales technical support, especially for software troubleshooting and recalibration.

What is the typical lead time for customized 6-axis Yaskawa robots?

Standard modification cycles range from 20–40 days, depending on complexity. Simple cosmetic or packaging customizations require 2–3 weeks. Full system integrations involving new control architecture or multi-axis synchronization may extend to 60 days. Allow additional time for international shipping via air or sea freight.

Do suppliers offer sample units or prototypes?

Sample policies vary. Some suppliers provide pre-configured demo units for evaluation, often at reduced cost or refundable deposit. Fully customized prototypes typically incur non-recoverable engineering fees, particularly for software development or mechanical redesign. Negotiate sample credit against future bulk orders.

What are common customization options for 6-axis Yaskawa robots?

Available modifications include reach extension kits, increased payload mounts, specialized coatings for corrosive environments, custom paint colors, brand labeling, explosion-proof housings, and integrated linear rails. Software-level changes involve user-defined motion paths, HMI language localization, and SCADA/PLC communication protocols.

Can these suppliers handle global shipping and export compliance?

Yes, experienced suppliers manage export documentation and logistics under FOB, CIF, or DDP terms. Confirm compliance with destination regulations—especially CE for EU markets and NRTL certification for North America. Ensure proper packaging for long-distance transport to prevent damage to precision components.