A Machine At A Soft Drink Bottling Factory

CN

CN

CN

CN

About a machine at a soft drink bottling factory

Where to Find Suppliers for Soft Drink Bottling Machines?

China remains the global hub for soft drink bottling machinery manufacturing, with a concentrated cluster of specialized suppliers in Zhangjiagang, Jiangsu Province. This region accounts for over 70% of China’s beverage packaging equipment exports, driven by vertically integrated production ecosystems and proximity to major ports like Shanghai and Ningbo. Zhangjiagang alone hosts more than 200 machinery firms focused on liquid filling systems, leveraging regional expertise in stainless steel processing, automation engineering, and food-grade component sourcing.

The industrial cluster enables streamlined access to critical subsystems—including rinsing, filling, capping, labeling, and pasteurization units—produced within 50km supply networks. This integration reduces lead times by 25–30% compared to decentralized manufacturing regions. Buyers benefit from scalable solutions ranging from compact semi-automatic lines (500–1,000 bottles/hour) to fully automated turnkey plants capable of 6,000+ BPH output. Average delivery windows range from 30–45 days for standard configurations, with localized material sourcing cutting production costs by 20–35% versus Western or Southeast Asian alternatives.

How to Choose Soft Drink Bottling Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Expertise

Verify adherence to food safety standards such as FDA 21 CFR Part 113 and EU Hygiene Regulations. Equipment must utilize 304/316L stainless steel for wetted parts and incorporate CIP (Clean-in-Place) compatibility. Confirm supplier experience with carbonated beverage handling—including CO₂ saturation control, pressure stabilization, and nitrogen dosing systems. For international buyers, CE marking is essential for market access in Europe, while NSF certification adds value for North American operations.

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to support full-line assembly

- In-house engineering teams capable of designing complete blow-mold-fill-seal integrated systems

- On-site testing facilities for performance validation under real-world conditions

Cross-reference declared capacities with actual order histories and on-time delivery records (target ≥98%) to assess scalability and reliability.

Customization & Integration Scope

Leading suppliers offer configurable solutions across bottle types (PET, glass, aluminum), volumes (200ml–2L), and production speeds. Key customizable elements include filling technology (piston, gravity, or counter-pressure), labeling methods (shrink sleeve, glue, or self-adhesive), and integration with upstream blow molding or downstream packaging modules. Confirm availability of digital recipe management, laser date coding, and IoT-enabled monitoring systems for Industry 4.0 readiness.

Transaction Safeguards

Utilize secure payment mechanisms such as third-party escrow or letter of credit to mitigate risk. Prioritize suppliers with documented quality management systems (ISO 9001 certified preferred) and participation in verified trade programs. Conduct pre-shipment inspections via third-party auditors or virtual factory tours to validate build quality and compliance before dispatch.

What Are the Leading Soft Drink Bottling Machine Suppliers?

| Company Name | Location | Verified Supplier | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (Min. Order) |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang Baiji Machinery Co., Ltd. | Zhangjiagang, CN | Multispecialty Supplier | US $440,000+ | 100% | ≤5h | 50% | PET, glass, aluminum lines | $12,500–$15,500 |

| Zhangjiagang Comark Machinery Co., Ltd. | Zhangjiagang, CN | Multispecialty Supplier | US $400,000+ | 100% | ≤6h | 50% | PET, carbonated lines | $13,500–$14,500 |

| Zhangjiagang Wellmore Machinery Co., Ltd. | Zhangjiagang, CN | Multispecialty Supplier | - | 100% | ≤1h | - | PET, soda lines | $17,000–$30,000 |

| Zhangjiagang EQS Machinary Co., Ltd. | Zhangjiagang, CN | Multispecialty Supplier | US $460,000+ | 100% | ≤3h | 66% | PET, glass, complete lines | $15,000–$110,000 |

| Jiangmen Tings Drinking Water Equipment Co., Ltd. | Jiangmen, CN | Multispecialty Supplier | US $190,000+ | 100% | ≤6h | 33% | Filling machines, water treatment | $11,500–$144,000 |

Performance Analysis

Zhangjiagang-based suppliers dominate the mid-to-high-end segment, offering comprehensive customization and proven export performance. Zhangjiagang EQS Machinary stands out with a 66% reorder rate and broad technical scope, including combiblock systems and high-speed carbonation control. Baiji and Comark provide competitively priced entry-level lines with strong after-sales engagement, evidenced by 50% reorder rates. Wellmore excels in responsiveness (≤1h average reply time), making it ideal for urgent procurement cycles despite limited public revenue data. Jiangmen Tings offers cost-effective options starting at $11,500 but focuses primarily on water and low-carbonation applications, limiting suitability for high-pressure carbonated soft drinks (CSD).

FAQs

How to verify soft drink bottling machine supplier reliability?

Cross-check ISO 9001 or CE certifications through official registries. Request factory audit reports or video walkthroughs showing CNC machining, welding, and final assembly processes. Analyze customer reviews focusing on machine uptime, spare parts availability, and technical support response times.

What is the typical minimum order quantity (MOQ) and lead time?

Standard MOQ is 1 set for standalone machines and 1 unit for complete lines. Lead times average 30–45 days post-deposit, depending on complexity. Customized turnkey systems may require up to 60 days for fabrication, calibration, and testing.

Can suppliers accommodate custom bottle formats and production speeds?

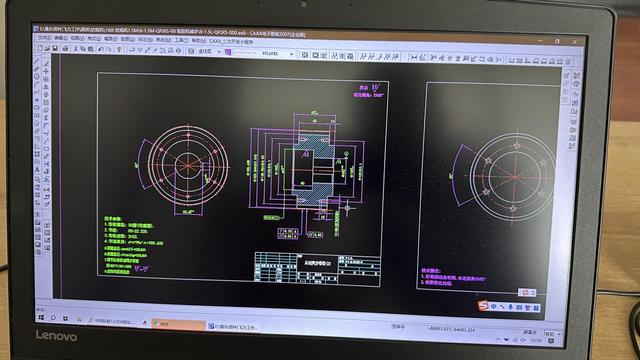

Yes, most suppliers support customization of bottle size (diameter: 40–100mm; height: 150–300mm), materials (PET, glass, aluminum), and output rates (500–6,000 bottles/hour). Provide CAD drawings or physical samples for mold and conveyor adjustments.

Do manufacturers provide installation and training support?

Many offer remote commissioning via video guidance. On-site service is typically available at additional cost, covering equipment setup, operator training, and process optimization. Confirm inclusion of user manuals, electrical schematics, and maintenance protocols in the contract.

How are machines packaged and shipped internationally?

Equipment is securely crated in seaworthy wooden cases with anti-vibration padding. FOB terms are standard; CIF can be arranged upon request. Most suppliers coordinate with freight forwarders experienced in handling heavy industrial cargo to destinations worldwide.