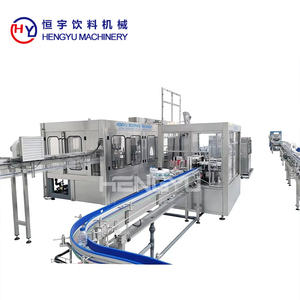

A Machine In A Soft Drink Factory Fills 600 Bottles

CN

CN

CN

CN

About a machine in a soft drink factory fills 600 bottles

Where to Find Soft Drink Filling Machine Suppliers?

China remains the global epicenter for beverage packaging machinery manufacturing, with Zhangjiagang in Jiangsu Province emerging as a dominant industrial cluster. This region hosts specialized manufacturers producing integrated filling systems capable of handling carbonated soft drinks at rates up to 600 bottles per hour (BPH) and beyond. The concentration of engineering expertise, component suppliers, and testing facilities within a 50km radius enables vertically integrated production, reducing assembly lead times by 20–30% compared to decentralized manufacturing regions.

Suppliers in this hub offer complete turnkey lines encompassing rinsing, filling, capping, labeling, and conveyance systems, often tailored for PET, glass, or aluminum containers. Local access to CNC machining, laser coding, and automation integration allows rapid prototyping and customization. Buyers benefit from scalable solutions—compact semi-automatic units for startups to fully automated monoblock systems for mid-tier producers—all supported by mature logistics networks that ensure export readiness within 45 days on average.

How to Choose Soft Drink Filling Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Verify compatibility with carbonated beverage standards, including counter-pressure filling technology to maintain CO₂ levels. CE or equivalent safety certification is essential for international deployment. Confirm supplier capability in integrating ancillary systems: bottle rinsers, liquid mixers, carbonation tanks, date printers, and tunnel pasteurizers. Request validation documentation for filling accuracy (±1–2ml tolerance) and sealing integrity under pressure.

Production Capability Verification

Assess infrastructure maturity through key indicators:

- Minimum factory area exceeding 3,000m² to support full-line assembly

- In-house engineering teams for custom line design and PLC programming

- Proven experience with 500–8,000 BPH systems across PET, glass, and can formats

Cross-reference online revenue data and reorder rates as proxies for market acceptance and post-sales reliability.

Transaction Safeguards and Quality Assurance

Prioritize suppliers offering third-party inspection options prior to shipment. Utilize secure payment mechanisms that release funds upon destination verification. Evaluate responsiveness (target ≤8 hours) and on-time delivery performance (ideally ≥95%) as indicators of operational discipline. Conduct video audits of production floors to confirm adherence to stated workflows and quality checkpoints.

What Are the Best Soft Drink Filling Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Min. Order Price (USD) | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang Baiji Machinery Co., Ltd. | Jiangsu, CN | US $440,000+ | 100% | ≤5h | 50% | $12,800 | 600–1,000 BPH carbonated lines | Bottle size, labeling, nitrogen dosing, cap type |

| Zhangjiagang Sky Machine Co., Ltd. | Jiangsu, CN | US $1,100,000+ | 100% | ≤4h | 50% | $15,000 | 600–6,000 BPH, monoblock systems | Filling heads, carbonation control, bottle design |

| Zhangjiagang City Nan Cheng Machinery Co., Ltd. | Jiangsu, CN | US $520,000+ | 100% | ≤8h | 100% | $1,500 | Water & soda lines, 600–8,000 BPH | Limited (core focus on standard models) |

| Zhangjiagang EQS Machinary Co., Ltd. | Jiangsu, CN | US $460,000+ | 100% | ≤3h | 66% | $25,000 | Premium compact carbonated lines | Label graphics, color, material finishes |

| Zhangjiagang Alps Machine Co., Ltd. | Jiangsu, CN | US $600,000+ | 95% | ≤4h | 50% | $13,000 | PET, can, and sparkling water systems | Bottle blowing integration, labeling, capacity tuning |

Performance Analysis

Zhangjiagang Sky Machine leads in scale and system complexity, supporting high-capacity monoblock lines with robust customization. Baiji Machinery offers competitive entry-level pricing ($12,800–$15,500 range) while maintaining full-line integration and strong after-sales metrics. Nan Cheng stands out with a 100% reorder rate, indicating high customer retention despite more standardized offerings. EQS targets premium niche markets with higher-priced units ($25,000+), emphasizing aesthetic and branding customization. Alps Machine provides broad format flexibility across cans and PET, though its 95% on-time delivery rate warrants closer shipment monitoring.

FAQs

What is the typical lead time for a 600 BPH soft drink filling machine?

Standard configurations require 30–45 days for production and pre-shipment testing. Customized lines with integrated blow molding or labeling may extend to 60 days. Air freight adds 5–7 days; sea freight ranges from 15–35 days depending on destination.

Do suppliers offer customization for bottle size and shape?

Yes, most suppliers support adjustable grippers, changeable star wheels, and programmable PLC settings for bottles ranging from 200ml to 2L. Custom molds or neck finish tooling may incur additional fees and extended timelines.

What certifications should a reliable supplier have?

CE marking is standard for electrical and mechanical safety. ISO 9001 indicates structured quality management. While not always present in listings, compliance with food-grade material standards (e.g., FDA-approved seals and contact parts) should be confirmed during technical review.

Can suppliers provide full production lines?

Yes, all listed suppliers offer end-to-end solutions including water treatment, mixing, carbonation, filling, capping, labeling, and packaging. Integration with depalletizers, conveyors, and inspection systems is available upon request.

Is on-site installation and training included?

Most suppliers include remote commissioning via video guidance. On-site technician dispatch is typically offered at an additional cost, covering machine setup, operator training, and process optimization for 5–7 days.