A Machine In A Soft Drink Factory Fills 840

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About a machine in a soft drink factory fills 840

Where to Find Soft Drink Filling Machine Suppliers?

China remains the global hub for beverage packaging machinery manufacturing, with key production clusters concentrated in Jiangsu and Shanghai. These regions host specialized industrial ecosystems focused on liquid filling systems, particularly for carbonated soft drinks (CSD), juices, and bottled water. Zhangjiagang, located in Jiangsu province, is recognized as a core manufacturing center, housing over 40% of China’s beverage line equipment suppliers. The city benefits from proximity to major steel and precision component suppliers, reducing material procurement lead times by 20–25% compared to offshore alternatives.

The region's vertically integrated supply chains enable full-cycle production—from blow molding and rinsing to filling, capping, and labeling—within single-line configurations. This integration allows suppliers to offer complete turnkey solutions at competitive price points. Buyers benefit from localized technical expertise, scalable production capacities, and streamlined logistics via Shanghai Port, one of Asia’s busiest export hubs. Average lead times for standard soft drink filling lines range from 30 to 60 days, with customization options widely available across bottle types (PET, glass, can) and output volumes (up to 840 bottles per minute).

How to Choose Soft Drink Filling Machine Suppliers?

Selecting a reliable supplier requires due diligence across technical, operational, and transactional dimensions:

Technical Compliance & System Design

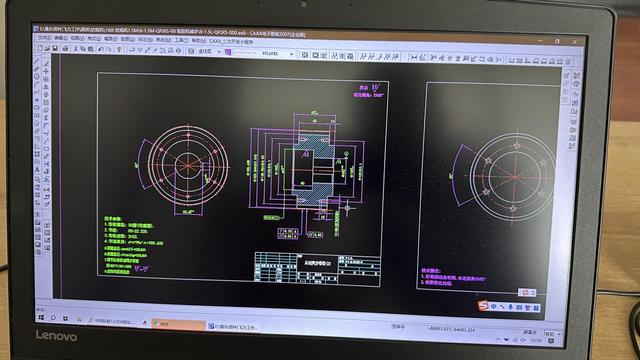

Confirm that equipment meets international safety and hygiene standards such as CE or ISO 9001. For carbonated beverages, verify the use of isobaric filling technology to maintain CO₂ levels during bottling. Evaluate system specifications including nozzles per head, line speed (BPM), compatibility with bottle sizes (250ml–2L), and integration capability with upstream/downstream units like conveyors, labelers, and pasteurizers.

Production Capability Verification

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² to support assembly of full production lines

- In-house engineering teams capable of customizing line layouts, control systems (PLC/HMI), and sanitation protocols

- Proven experience in delivering integrated systems—including water treatment, preform heating, stretch blow molding, and final packaging

- Cross-reference on-time delivery performance (target ≥95%) and reorder rates as indicators of customer satisfaction

Transaction Safeguards & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Request detailed documentation, including machine schematics, material certifications (e.g., stainless steel grade 304/316), and test run videos. Prioritize suppliers offering sample validation or remote commissioning support. Post-delivery service capabilities—such as technician training, spare parts availability, and response time for troubleshooting—are critical for minimizing downtime.

What Are the Best Soft Drink Filling Machine Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Shanghai Ok Machinery Co., Ltd. | Shanghai, CN | Filling Machines, Stretch Blow Moulding Machines, Multi-Function Packaging Lines | Bottle volume, label design, nozzle count, line speed, whole-line integration | 100% | ≤7h | 25% | US $1.3M+ |

| Zhangjiagang Huazhen Machinery Co., Ltd. | Zhangjiagang, CN | Carbonated Soft Drink Lines, Glass Bottle Fillers, Complete Production Systems | Bottle size, material, labeling, carbonation level, filtration, whole-line layout | 100% | ≤1h | 100% | US $640K+ |

| Ace-Filling (Suzhou) Packaging Machinery Co., Ltd. | Suzhou, CN | Full-Automatic CSD Fillers, Juice Lines, High-Speed Bottling Systems | Sealing type, sterilization method, hot/cold fill, bottle shape, bph output | 100% | ≤2h | 28% | US $140K+ |

| Zhangjiagang Wellmore Machinery Co., Ltd. | Zhangjiagang, CN | Can Fillers, Carbonated Beverage Lines, Bottling Plants | Color, material, logo, packaging format, graphic interface | 100% | ≤1h | - | - |

| Zhangjiagang Alps Machine Co., Ltd. | Zhangjiagang, CN | Carbonated Water Plants, Tin Can Lines, Beverage Filling Systems | Labeling, bottle blowing, capacity, material grade, graphic controls | 95% | ≤3h | 50% | US $600K+ |

Performance Analysis

Zhangjiagang-based suppliers dominate responsiveness and specialization in carbonated beverage systems. Zhangjiagang Huazhen stands out with a 100% reorder rate and sub-1-hour average response time, indicating high client retention and operational agility. Shanghai Ok Machinery offers broad product diversity and high online revenue volume, suggesting strong market presence and scalability. Ace-Filling (Suzhou) provides cost-effective solutions with notable customization depth, particularly in sealing and sterilization configurations. While Zhangjiagang Wellmore lacks reorder data, its consistent on-time delivery and rapid response align with regional reliability benchmarks. Zhangjiagang Alps demonstrates robust after-sales engagement with a 50% reorder rate, despite slightly lower punctuality. Buyers seeking fully integrated lines should prioritize suppliers with documented experience in end-to-end plant installation and validation testing.

FAQs

How to verify soft drink filling machine supplier reliability?

Validate compliance with ISO 9001 and CE standards through official certification databases. Request factory audit reports, equipment test videos, and references from prior international clients. Analyze order history for consistency in delivery and post-sale support.

What is the typical lead time for a customized soft drink filling line?

Standard configurations ship within 30–45 days. Fully customized lines, especially those integrating blow molding and water treatment, require 50–70 days depending on complexity and component sourcing.

Do suppliers offer OEM or ODM services?

Yes, most suppliers provide OEM branding (logo, color scheme, control panel graphics) and ODM engineering for unique bottle formats, output speeds, or automation levels. Custom molds and PLC interfaces are commonly supported.

What are common MOQ and pricing ranges?

Minimum order quantity is typically 1 set. Entry-level semi-automatic lines start at $5,000–$8,000, while fully automatic carbonated beverage lines with 840 BPM capacity range from $25,000 to $65,000 based on configuration and materials.

Can suppliers handle global shipping and installation?

Yes, experienced manufacturers coordinate sea freight under FOB or CIF terms and offer remote or on-site commissioning. Some provide technician dispatch services for initial setup and staff training, subject to contractual agreement.