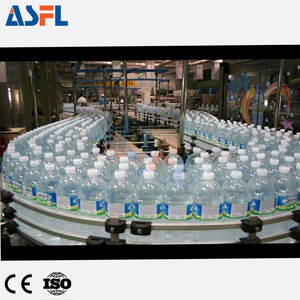

A Machine In A Soft Drink Factory

Top sponsor listing

Top sponsor listing

1/24

1/24

1/10

1/10

1/22

1/22

1/27

1/27

1/16

1/16

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

1/17

1/17

1/3

1/3

1/15

1/15

1/3

1/3

About a machine in a soft drink factory

Where to Find Soft Drink Machine Suppliers?

China remains the global hub for soft drink production machinery manufacturing, with key industrial clusters concentrated in Jiangsu and Zhejiang provinces. These regions host vertically integrated facilities specializing in complete beverage processing lines—from bottle blowing and water treatment to filling, labeling, and packaging. Zhangjiagang, a city within Jiangsu, has emerged as a dominant center, housing multiple suppliers capable of delivering fully automated carbonated beverage production systems with output capacities ranging from 2,000 to 24,000 bottles per hour (BPH).

The region’s competitive advantage lies in its mature supply chain ecosystem, where component manufacturers, engineering teams, and logistics providers operate in close proximity. This integration enables streamlined production cycles, localized sourcing of materials such as stainless steel and food-grade polymers, and reduced lead times—typically 30–60 days for standard configurations. Buyers benefit from economies of scale, with cost savings of 20–35% compared to equivalent European or North American suppliers, while maintaining compliance-ready designs suitable for international markets.

How to Choose Soft Drink Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer end-to-end production line integration, including core components such as water treatment systems, carbonation units, rotary fillers, capping machines, labeling systems, and shrink-wrapping equipment. Prioritize vendors with documented experience in carbonated soft drinks (CSD) and energy beverages, ensuring compatibility with high-pressure sealing and CO₂ management protocols. Request validation of critical performance metrics: filling accuracy (±1%), carbonation levels (2.0–4.5 volumes), and hygiene standards compliant with HACCP and FDA guidelines.

Production & Customization Capacity

Assess supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² supporting full-line assembly

- In-house engineering teams offering customization for bottle size (PET, glass, can), output rate (1,000–24,000 BPH), and material handling (linear vs. rotary systems)

- Support for modular upgrades, including UV sterilization, laser coding, CIP (Clean-in-Place) systems, and semi-automatic to fully automatic transitions

Cross-reference product listings with actual production data, targeting suppliers offering at least 10+ machine types and proven reorder rates above 30%.

Quality Assurance & Transaction Security

Require ISO 9001 certification as a baseline quality indicator. For export-focused buyers, verify CE marking and electrical safety compliance (e.g., IEC 60204-1). Analyze supplier responsiveness (target ≤7 hours) and on-time delivery performance (ideal ≥95%). Utilize secure payment mechanisms such as escrow services and conduct pre-shipment inspections through third-party agencies. Pilot testing is strongly recommended—evaluate sample runs for leakage integrity, label alignment, and process stability under continuous operation.

What Are the Best Soft Drink Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Scope | Price Range (Set) |

|---|---|---|---|---|---|---|---|

| Ok Machinery Co., Ltd. | Filling Machines (1134); Labeling Machines (22); Water Treatment (20) | US $240,000+ | 100% | ≤7h | <15% | Bottle volume, labeling, film wrapping, complete line integration | $18,000–$45,000 |

| Zhangjiagang Alps Machine Co., Ltd. | Complete small-scale to industrial lines | US $590,000+ | 89% | ≤4h | 33% | Bottle size, carbonation capacity, graphic design, labeling | $18,000–$45,000 |

| Zhangjiagang Comark Machinery Co., Ltd. | Carbonated filling, blow molding, bottling lines | US $210,000+ | 100% | ≤7h | 100% | Bottle type, output rate, UV sterilizer, shrink sleeve, laser printer | $11,000–$13,500 |

| Zhangjiagang Honor Machine Co., Ltd. | Filling, mixing, bottling, carbonation systems | US $310,000+ | 100% | ≤2h | 100% | Filling heads, agitator design, labeling, CIP cleaning | $13,600–$19,900 |

| Suzhou New Crown Machine Co., Ltd. | Customizable high-efficiency lines up to 24,000 BPH | US $5,000+ | 100% | ≤1h | 50% | Packaging design, logo integration, voltage customization | $23,000–$210,000 |

Performance Analysis

Suppliers like Zhangjiagang Comark and Zhangjiagang Honor demonstrate strong customer retention (100% reorder rate) and consistent delivery performance, indicating reliability for repeat procurement. Suzhou New Crown stands out for high-capacity solutions (up to 24,000 BPH) and rapid response times (≤1h), making it suitable for large-scale beverage producers requiring fast technical engagement. Ok Machinery leads in product diversity with over 1,100 filling machine listings, though its low reorder rate suggests potential gaps in post-sale support. Price-sensitive buyers may consider Comark’s sub-$12,000 entry-level systems, while those seeking scalable automation should evaluate Suzhou New Crown’s premium-tier $190,000+ lines. All top-tier suppliers offer customization for voltage (220V/380V), bottle formats, and hygiene systems, but only select vendors provide full project engineering support for turnkey installations.

FAQs

How to verify soft drink machine supplier reliability?

Cross-check ISO and CE certifications with issuing bodies. Request documentation on material traceability, weld integrity reports, and pressure testing results for carbonation tanks. Evaluate supplier credibility through verifiable transaction history, customer references, and video audits of production floors and quality control stations.

What is the typical lead time for soft drink production lines?

Standard configurations require 30–45 days for manufacturing and testing. Customized or high-output systems (above 16,000 BPH) may take 50–70 days. Add 10–20 days for international shipping via sea freight, depending on destination port congestion and customs procedures.

Do suppliers support global shipping and installation?

Yes, established manufacturers offer worldwide delivery under FOB or CIF terms. Many provide optional on-site commissioning, technician training, and remote troubleshooting. Confirm inclusion of English-language manuals, PLC interfaces, and spare parts kits before order finalization.

Are samples or pilot machines available?

Full-line sampling is uncommon due to size and cost, but suppliers often allow functional testing of individual units (e.g., filler or capper) before full procurement. Some offer rental or demo units for process validation. Expect partial cost recovery policies unless bundled with larger orders.

What customization options are typically offered?

Buyers can specify bottle dimensions (200ml–2L), container type (PET, glass, can), output speed, automation level (semi-auto to full auto), labeling method (sleeve, wraparound, self-adhesive), and integration of CIP, UV sterilization, or leak detection systems. Electrical specifications (voltage, frequency) are routinely adapted to regional standards.