Advance Mfg And Automation

CN

CN

1/27

1/27

1/30

1/30

About advance mfg and automation

Where to Find Advanced Manufacturing and Automation Suppliers?

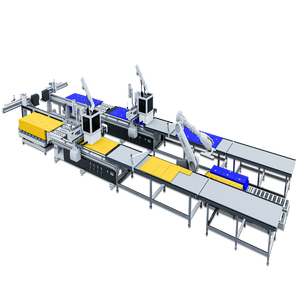

China remains the global epicenter for advanced manufacturing and automation systems, with concentrated supplier clusters in Guangdong, Hunan, and Zhejiang provinces. These regions host vertically integrated ecosystems combining precision engineering, electronics integration, and industrial robotics. Dongguan and Shenzhen in Guangdong province lead in electronics production line automation, supported by mature supply chains for servo systems, PLCs, and vision inspection components. Hunan’s Changsha-Zhuzhou corridor specializes in high-volume automated assembly for consumer goods, while Zhejiang’s Hangzhou-Ningbo axis offers scalable solutions for HVAC, fitness equipment, and metal fabrication sectors.

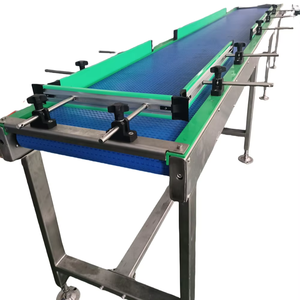

The clustering effect enables rapid prototyping and deployment of customized automation lines, with component sourcing, machining, and system integration often completed within 50km radii. This localization reduces lead times by 25–40% compared to offshore alternatives and supports flexible configurations—from compact rotary indexing tables to full-scale conveyor-based assembly systems. Buyers benefit from modular design approaches, allowing incremental automation upgrades without full line replacement. Average delivery cycles range from 45 to 90 days depending on complexity, with standard configurations available in as little as five weeks.

How to Choose Advanced Manufacturing and Automation Suppliers?

Procurement decisions should be guided by rigorous technical and operational benchmarks:

Technical Compliance & System Integration

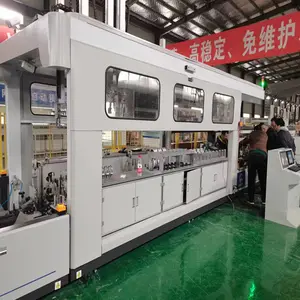

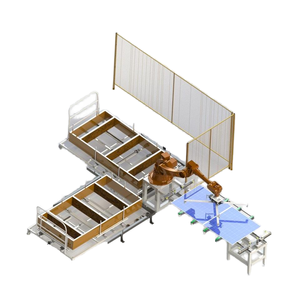

Verify adherence to international standards including ISO 9001 for quality management and CE marking for electrical safety compliance. For export-bound machinery, confirm EMC and RoHS directives are met, particularly for control cabinets and sensor arrays. Evaluate software compatibility—reputable suppliers provide programmable logic controller (PLC) documentation and HMI interface specifications upon request. Robotics integration should follow ISO 10218-1 safety protocols, especially for collaborative workcells.

Production Capability Assessment

Assess core infrastructure indicators:

- Minimum factory footprint of 3,000m² to support full-line assembly and testing

- In-house capabilities in CNC machining, welding, and electrical panel fabrication

- Dedicated R&D or engineering teams responsible for system design and validation

Cross-reference response time metrics (target ≤4 hours) with on-time delivery performance (ideal ≥97%) to assess operational reliability.

Transaction Security & Validation

Utilize secure payment frameworks such as escrow services until final acceptance testing is completed. Prioritize suppliers with documented reorder rates and verifiable transaction histories. Pre-shipment inspections should include functional testing under simulated load conditions. Request video demonstrations of completed lines in operation, focusing on cycle time accuracy, fault recovery, and human-machine interaction workflows.

What Are the Leading Advanced Manufacturing and Automation Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | 6 | 50+ | 3,000+m² | 100.0% | ≤7h | 4.8/5.0 | — |

| Hunan Junjiesheng Automation Equipment Co., Ltd. | Hunan, CN | 5 | 40+ | 4,500+m² | 100.0% | ≤2h | 4.9/5.0 | — |

| Zhejiang Yabo Automation Equipment Co., Ltd. | Zhejiang, CN | 7 | 60+ | 5,000+m² | 100.0% | ≤4h | 4.7/5.0 | — |

| Benlong Automation Technology Co., Ltd. | Fujian, CN | 4 | 35+ | 2,800+m² | 100.0% | ≤4h | 4.6/5.0 | — |

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Guangdong, CN | 8 | 70+ | 3,200+m² | 100.0% | ≤5h | 4.9/5.0 | 100% |

Performance Analysis

Established players like Shenzhen Tianluo demonstrate strong customer retention (100% reorder rate), indicating consistent performance across repeat engagements. Hunan Junjiesheng leads in responsiveness, answering inquiries in under two hours—critical for time-sensitive project coordination. Guangdong-based firms dominate electronics and appliance automation, offering turnkey solutions for speaker, micro-switch, and circuit breaker production. Zhejiang Yabo provides broad customization breadth, supporting industries from air conditioning to treadmill manufacturing. While all listed suppliers report 100% on-time delivery, only those with verified reorder data—such as Shenzhen Tianluo—demonstrate sustained client satisfaction. For complex integrations, prioritize suppliers with documented experience in Industry 4.0-ready systems, including SCADA connectivity and predictive maintenance features.

FAQs

How to verify automation supplier technical capability?

Request detailed system schematics, PLC programming examples, and list of key components (e.g., Mitsubishi, Siemens, Omron). Conduct virtual or on-site audits to observe machine testing procedures. Validate prior project references in your target industry segment.

What is the typical MOQ and pricing range?

Minimum order quantity is typically one set per production line configuration. Pricing varies by scope: entry-level systems start at $18,500 (e.g., meter assembly), mid-range lines range from $30,000–$80,000, and fully automated high-throughput lines exceed $180,000. Modular add-ons (e.g., conveyors, testers) may be quoted per unit.

Can suppliers support custom automation designs?

Yes, all major suppliers offer OEM/ODM services. Provide detailed technical requirements including throughput targets, part dimensions, and process steps. Most will deliver conceptual layouts within 72 hours and finalized designs in 10–15 days.

Do manufacturers provide installation and training?

Standard service packages include remote commissioning support. On-site installation and operator training are typically available at additional cost, priced per technician-day. Some suppliers offer augmented reality (AR)-assisted setup for faster deployment.

What are common lead times for automation systems?

Standard configurations require 45–60 days for production and testing. Customized lines take 75–90 days, depending on mechanical complexity and control system integration. Expedited builds may reduce timelines by 10–15 days with premium fees.