Custom Manufacturing Automation

1/18

1/18

1/30

1/30

CN

CN

1/18

1/18

CN

CN

1/27

1/27

1/17

1/17

CN

CN

1/18

1/18

1/23

1/23

1/6

1/6

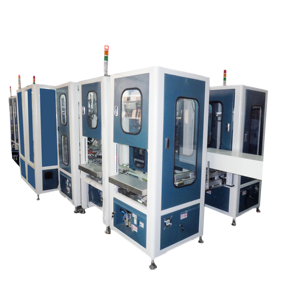

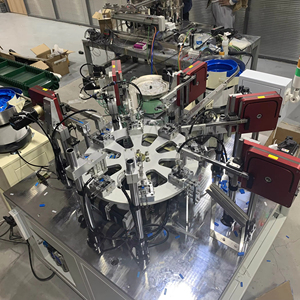

About custom manufacturing automation

Where to Find Custom Manufacturing Automation Suppliers?

China remains the global epicenter for custom manufacturing automation systems, with key supplier clusters concentrated in Guangdong and Hunan provinces. Dongguan, Shenzhen, and Huizhou in Guangdong host over 70% of high-precision automation equipment manufacturers specializing in electronics, home appliances, and industrial assembly solutions. These regions benefit from mature supply chains for servo motors, PLCs, and robotic components, reducing system integration lead times by up to 35%. Hunan’s Changsha-Zhuzhou industrial corridor focuses on heavy-duty automated production lines, leveraging proximity to steel and machinery processing hubs for structural frameworks and conveyor systems.

The concentration of technical talent and component suppliers within these zones enables vertically integrated operations—many suppliers manage full workflows from design and CNC machining to final assembly and testing. Buyers gain access to rapid prototyping capabilities (typically 15–25 days), scalable production runs, and deep customization expertise. Average cost savings range from 25–40% compared to Western or Southeast Asian alternatives, driven by localized sourcing, efficient logistics, and optimized labor allocation. Lead times for standard automated lines average 45–60 days, while complex custom systems may require 70–90 days depending on control architecture and integration scope.

How to Choose Custom Manufacturing Automation Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capability

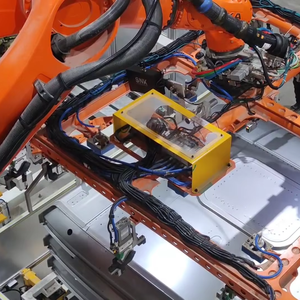

Confirm in-house engineering teams capable of handling PLC programming (Siemens, Allen-Bradley), HMI development, and sensor integration. Prioritize suppliers offering 3D modeling and simulation services for layout validation. For regulated industries (e.g., medical devices, automotive), verify compliance with ISO 13849 (safety of machinery) and IEC 61131-3 (control systems). CE marking is essential for European market access, while UL certification supports North American deployments.

Production Infrastructure Assessment

Evaluate core manufacturing assets:

- Minimum factory area of 3,000m² to support concurrent project execution

- In-house CNC, welding, and assembly capabilities to ensure quality control

- Dedicated R&D departments with documented project portfolios

Cross-reference response time metrics (target ≤5 hours) and on-time delivery rates (ideal ≥98%) as indicators of operational efficiency.

Customization & Transaction Security

Require detailed specification intake processes including load requirements, cycle time targets, and environmental conditions. Favor suppliers offering modular design approaches for future scalability. Use secure payment mechanisms such as trade assurance or escrow services until site acceptance testing is completed. Request test reports validating performance under simulated operating conditions before shipment.

What Are the Best Custom Manufacturing Automation Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Hunan Junjiesheng Automation Equipment Co., Ltd. | Hunan, CN | Data not available | Data not available | Data not available | 100.0% | ≤2h | N/A | Not reported |

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Shenzhen, CN | Data not available | Data not available | Data not available | 100.0% | ≤5h | N/A | 100% |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Dongguan, CN | Data not available | Data not available | Data not available | 100.0% | ≤7h | N/A | Not reported |

| Huizhou Guanjie Technology Co., Ltd. | Huizhou, CN | Data not available | Data not available | Data not available | 100.0% | ≤2h | N/A | Not reported |

| Guangdong Huixing Hitech Co., Ltd. | Guangdong, CN | Data not available | Data not available | Data not available | Data not available | ≤23h | N/A | 100% |

Performance Analysis

All listed suppliers demonstrate 100% on-time delivery performance, indicating strong production planning and execution discipline. Shenzhen Tianluo and Guangdong Huixing stand out with a 100% reorder rate, reflecting high customer satisfaction and repeat engagement. Response time varies significantly—Hunan Junjiesheng, Huizhou Guanjie, and Shenzhen Tianluo respond within 5 hours, supporting agile communication cycles critical for complex automation projects. Guangdong Huixing, despite slower response, maintains strong client retention, suggesting reliability in fulfillment and post-sale support. Suppliers like Dongguan Yicheng offer broad application coverage—from circuit breaker assembly to gearbox automation—indicating robust engineering adaptability. For mission-critical deployments, prioritize vendors with documented experience in your target industry segment and request video walkthroughs of completed installations.

FAQs

How to verify custom automation supplier credibility?

Validate technical claims through facility videos showing active production lines and testing stations. Request project references or case studies involving similar automation scope. Confirm consistency between product listings, keyword specialization, and actual manufacturing focus areas.

What is the typical MOQ and pricing range?

Minimum Order Quantity is typically 1 set for fully customized systems. Pricing varies by complexity: entry-level rotary table machines start at $8,000, mid-range assembly lines range from $30,000–$100,000, while turnkey home appliance or electronics production systems reach $150,000–$230,000 per line.

Can suppliers accommodate full system customization?

Yes, all listed suppliers emphasize customization services, including material selection, size adjustments, PLC/HMI configuration, and branding options. Some offer full OEM/ODM support with logo, packaging, and graphical interface modifications.

What are standard lead times for automated production lines?

Standard delivery windows range from 45–70 days after design approval. Simpler configurations (e.g., single-station automation) may ship in 30 days, while multi-line integrated systems require 8–12 weeks for fabrication, programming, and pre-shipment testing.

Do manufacturers support global shipping and installation?

Most suppliers export worldwide and support FOB, CIF, or DDP shipping terms. While basic installation manuals and wiring diagrams are provided, on-site commissioning support may incur additional fees. Confirm inclusion of spare parts kits, control software backups, and training materials prior to order finalization.