Advanced Circuit Boards

Top sponsor listing

Top sponsor listing

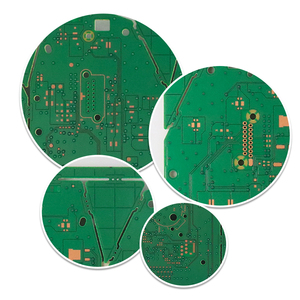

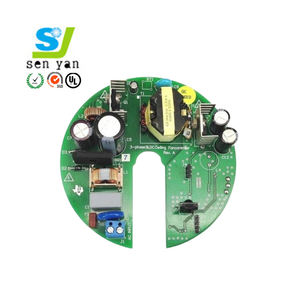

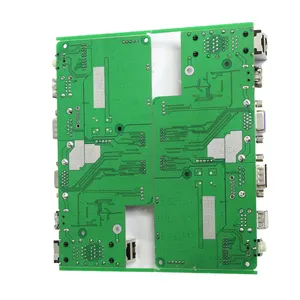

About advanced circuit boards

Where to Find Advanced Circuit Board Suppliers?

China remains the central hub for advanced circuit board manufacturing, with Shenzhen and Guangzhou in Guangdong Province emerging as key production clusters. These regions host vertically integrated supply chains that support rapid prototyping and high-volume PCB & PCBA production. Shenzhen’s ecosystem excels in R&D-intensive applications, offering access to specialized material suppliers, design engineers, and testing facilities within a 30km radius, enabling faster iteration cycles.

The industrial infrastructure supports diverse fabrication techniques—including multilayer, rigid-flex, ceramic, and aluminum-based substrates—enabling customization for aerospace, IoT, and industrial automation sectors. Localized sourcing of base materials such as FR4, Rogers, and polyimide reduces lead times by 15–25% compared to offshore alternatives. Buyers benefit from scalable production models, with standard order fulfillment averaging 7–15 days for prototypes and 18–25 days for bulk assemblies, depending on complexity.

How to Choose Advanced Circuit Board Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Compliance

Verify adherence to IPC-A-600 and IPC-A-610 standards for acceptability of printed boards and assemblies. For regulated industries (medical, automotive, aerospace), confirm RoHS and ISO 9001 compliance. Demand documentation for impedance control, thermal management, and solder mask accuracy, particularly for HDI and flexible designs.

Production Infrastructure Assessment

Evaluate the following indicators of manufacturing maturity:

- Minimum 10-layer lamination capability for complex multilayer PCBs

- In-house SMT lines with automated optical inspection (AOI) and X-ray testing

- Support for Gerber, IPC-2581, and ODB++ file formats with DFM analysis turnaround under 24 hours

Cross-reference product listings with on-time delivery performance (target ≥95%) and response time (ideally ≤2 hours) to assess operational responsiveness.

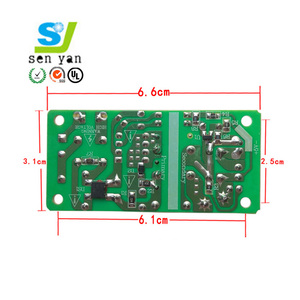

Customization and Quality Assurance

Prioritize suppliers offering full turnkey services—from bare board fabrication to component sourcing, assembly, and labeling—with traceable QC processes. Confirm capabilities in color coding, logo printing, and custom packaging. Reorder rate above 30% indicates customer retention and service consistency. Request sample batches to validate solder joint integrity, layer alignment, and electrical continuity before scaling orders.

What Are the Best Advanced Circuit Board Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Kinglisheng(Shenzhen) Electronic & Technology Co., Limited | PCBA (412), Other PCB & PCBA (133), Multilayer PCB (38) | 91% | ≤2h | 38% | US $370,000+ | Color, size, flexible design, cloning, Gerber support, material options |

| Shenzhen Linghangda Technology Co., Ltd. | Other PCB & PCBA (dominant), Development Boards | 100% | ≤9h | <15% | US $3,000+ | Color, size, logo, material, packaging label |

| Guangzhou Lingfeite Electronics Co., Ltd. | Other Service Equipment (90), Vending Machines (73), Other PCB & PCBA (60) | 100% | ≤2h | 15% | US $30,000+ | Limited direct PCB customization noted |

| Shenzhen Wanfeng Technology Co., Ltd. | Drone/UAV PCBA, Rigid-Flex PCB, Custom Smart Electronics | 100% | ≤1h | 66% | US $420,000+ | Color, size, logo, packaging, material, graphic design |

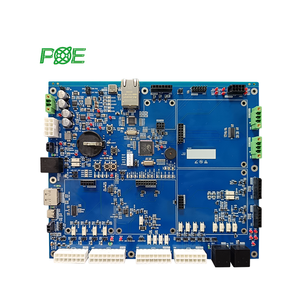

| INTELLISENSE TECHNOLOGY | PCBA (10,447), Software (7,999), GPS Modules | - | ≤4h | - | - | High volume PCBA specialization, system-level integration |

Performance Analysis

Shenzhen-based suppliers dominate in responsiveness and customization depth. Shenzhen Wanfeng Technology stands out with a 66% reorder rate and sub-1-hour response time, indicating strong client satisfaction in drone and smart electronics segments. Kinglisheng offers broadest PCB diversity with verified mid-volume output and 38% repeat business. INTELLISENSE TECHNOLOGY demonstrates scale in PCBA and embedded systems but lacks disclosed delivery metrics. Linghangda and Lingfeite show perfect on-time records but lower reorder rates, suggesting project-based or niche engagement models. Buyers requiring fast-turn engineering support should prioritize companies with ≤2h response times and proven multilayer or flex-rigid production experience.

FAQs

How to verify advanced circuit board supplier reliability?

Review technical documentation including stack-up diagrams, impedance reports, and material certifications (e.g., UL796). Confirm traceability through batch numbering and test logs. Utilize third-party inspection services for pre-shipment audits, especially for orders exceeding 1,000 units.

What is the typical minimum order quantity (MOQ)?

Most suppliers offer MOQs of 1–10 pieces for prototypes and small batches. High-complexity boards (e.g., 12+ layers, blind vias) may require MOQs of 25–50 units. Turnkey PCBA services often set MOQ based on component availability and setup costs.

Do suppliers support full turnkey PCBA?

Yes, leading suppliers provide component procurement, BOM optimization, and assembly verification. Confirm whether they accept alternative part substitutions and perform functional testing. Top-tier providers offer digital reporting with AOI images and test results.

What file formats are required for submission?

Standard requirements include Gerber (RS-274X), drill files (Excellon), and centroid data for SMT. For enhanced DFM, submit ODB++ or IPC-2581. Include detailed assembly drawings and netlists for complex boards.

How long does sampling take for advanced PCBs?

Simple single/double-sided boards: 5–7 days. Multilayer (6–12 layers): 10–14 days. Rigid-flex or high-frequency materials (e.g., Rogers): 14–21 days. Add 3–5 days for component sourcing and assembly validation in PCBA projects.