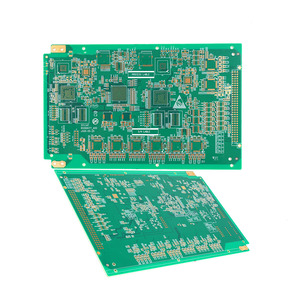

Advanced Circuits Pcb

Top sponsor listing

Top sponsor listing

1/31

1/31

CN

CN

1/23

1/23

1/27

1/27

1/37

1/37

1/44

1/44

1/15

1/15

1/38

1/38

1/34

1/34

1/26

1/26

About advanced circuits pcb

Where to Find Advanced Circuits PCB Suppliers?

China remains the global epicenter for advanced printed circuit board (PCB) manufacturing, with Shenzhen and Suzhou emerging as key production hubs due to their dense electronics ecosystems. Shenzhen hosts over 70% of China’s high-mix, low-to-medium volume PCB fabricators, leveraging proximity to component distributors, contract manufacturers, and R&D centers. Suzhou's industrial parks support full-turnkey operations, integrating multilayer lamination, surface mount technology (SMT), and automated optical inspection (AOI) under ISO-controlled environments.

These clusters enable rapid prototyping (24–72 hour turnaround for 4–8 layer boards) and scalable production, supported by vertically integrated supply chains that reduce material lead times by 25–40%. Buyers benefit from concentrated technical expertise in HDI, rigid-flex, and high-frequency substrates (e.g., Rogers, FR4), with localized access to impedance-controlled etching, laser drilling, and conformal coating services. Average cost savings range from 18–35% compared to North American or European suppliers, particularly for complex multilayer designs requiring tight tolerances.

How to Choose Advanced Circuits PCB Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria:

Technical & Quality Compliance

Confirm adherence to IPC-6012 Class 2/3 standards for performance reliability. Essential certifications include ISO 9001:2015 for quality management and IATF 16949 for automotive-grade PCBs. For EU and North American markets, RoHS and REACH compliance is mandatory. Request process capability (Cpk) data for critical processes such as plating thickness control and solder mask registration.

Production Capability Assessment

Evaluate core manufacturing parameters:

- Layer count capacity: Minimum 1–20 layers, with HDI and sequential lamination for high-density applications

- Material handling: Experience with FR4, Rogers, polyimide, and metal-core substrates

- In-house capabilities: SMT lines, BGA rework stations, AOI/X-ray inspection, and functional testing

Cross-reference supplier claims with on-time delivery rates (>95% recommended) and reorder rates as indicators of customer satisfaction.

Transaction & Risk Mitigation

Utilize secure payment mechanisms such as escrow or letter of credit for initial orders. Prioritize suppliers offering free DFM (Design for Manufacturing) feedback and Gerber validation. Conduct sample testing for electrical continuity, thermal cycling resilience, and solder joint integrity before mass production. Lead times typically range from 5–15 days for prototypes and 10–25 days for batch production, depending on complexity.

What Are the Best Advanced Circuits PCB Suppliers?

| Company Name | Location | Verified Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

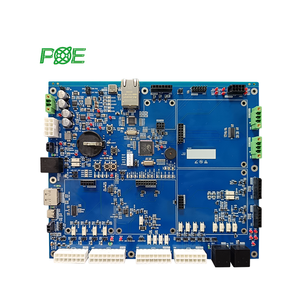

| Shenzhen Wanfeng Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | PCBA, Rigid-Flex PCB, Multilayer PCB | 100% | ≤1h | 55% | US $420,000+ | Color, material, size, logo, packaging, label, graphic |

| Guangzhou Leizzi Electronic Technology Co., Ltd. | Guangzhou, CN | Multispecialty Supplier | High Frequency PCB, HDI PCB, Rigid-Flex PCB, PCBA | 100% | ≤3h | - | - | Not specified |

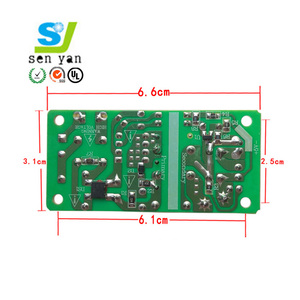

| Shenzhen Senyan Circuit Co., Ltd. | Shenzhen, CN | Unverified | Multilayer PCB, PCBA, Gerber File Support | 100% | ≤1h | 23% | US $30,000+ | Design documents, material, size, logo, panel, cloning |

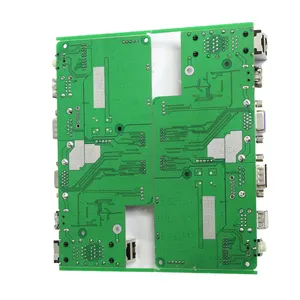

| Shenzhen Linghangda Technology Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | Circuit Board, EMS PCB, FR4 Boards | 100% | ≤9h | <15% | US $3,000+ | Color, material, size, logo, packaging, label, graphic |

| Suzhou Engine Electronic Technology Co., Ltd. | Suzhou, CN | Multispecialty Supplier | Multilayer PCB, PCBA, Other PCB & PCBA | 91% | ≤3h | 16% | US $50,000+ | Color, size, logo, packaging, label |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and technical agility, with three out of five achieving sub-3-hour average response times and 100% on-time delivery. Shenzhen Wanfeng Technology stands out with a 55% reorder rate and full turnkey PCBA services, indicating strong customer retention and service integration. Guangzhou Leizzi demonstrates specialization in high-frequency and rigid-flex technologies, suitable for aerospace and telecom applications, though transaction transparency is limited. Suzhou Engine Electronics offers stable output but lower reorder frequency, suggesting room for improvement in value-added services. For high-reliability sectors, prioritize suppliers with documented process controls, multi-layer inspection protocols, and experience in IPC Class 3 or MIL-PRF-55110 standards.

FAQs

How to verify advanced circuits PCB supplier reliability?

Validate certifications through accredited bodies and request audit trails for raw material sourcing (e.g., TG-rated laminates). Analyze customer reviews focusing on yield rates, DFM accuracy, and post-shipment support. Video factory tours can confirm in-house capabilities versus outsourcing practices.

What is the typical sampling timeline for custom PCBs?

Standard multilayer PCB samples take 5–7 days. HDI or rigid-flex boards require 10–14 days due to additional lamination cycles. Functional PCBA prototypes with component sourcing add 7–10 days. Air shipping adds 3–6 days internationally.

Do suppliers support small-batch and prototype orders?

Yes, most suppliers accept MOQs as low as 1 piece, especially for prototyping. Unit pricing decreases significantly at volumes above 100 units. Some offer free setup fees for trial runs exceeding 50 units.

Can suppliers handle end-to-end PCBA projects?

Leading manufacturers like Shenzhen Wanfeng and Suzhou Engine provide full turnkey solutions—including component procurement, SMT assembly, testing, and packaging—reducing buyer coordination burden. Ensure BOM management, counterfeit component prevention, and traceability are clearly defined in service agreements.

What customization options are available?

Common customization includes board dimensions, copper weight (1–3 oz), surface finishes (ENIG, HASL, Immersion Silver), silkscreen color, impedance control, and panelization style. For assemblies, options extend to labeling, packaging format, and firmware programming.