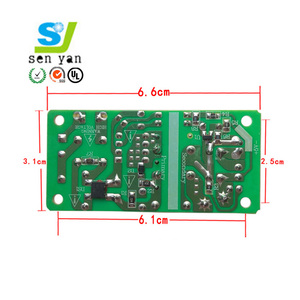

Advanced Circuit Pcb

CN

CN

About advanced circuit pcb

Where to Find Advanced Circuit PCB Suppliers?

China remains the global epicenter for advanced circuit PCB manufacturing, with key production clusters concentrated in Shenzhen and Guangzhou. These regions host vertically integrated supply chains that streamline prototyping, fabrication, and assembly processes—enabling rapid turnaround for both low-volume prototypes and high-volume production runs. Shenzhen alone accounts for over 60% of China’s electronics contract manufacturers, supported by a dense network of material suppliers, testing laboratories, and logistics providers operating within compact industrial zones.

The ecosystem supports agile manufacturing models, where multilayer, HDI, rigid-flex, and high-frequency PCBs are produced using automated optical inspection (AOI), impedance-controlled routing, and laser drilling technologies. Buyers benefit from localized component sourcing, reducing lead times by 25–40% compared to offshore alternatives. Typical production cycles range from 5–7 days for prototype batches to 12–18 days for mass production, depending on layer count and complexity. Cost efficiencies are further enhanced through economies of scale, with per-unit pricing as low as $0.30 for simple designs at volume.

How to Choose Advanced Circuit PCB Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Process Capabilities

Verify support for required specifications including layer counts (up to 32+ layers), materials (FR-4, Rogers, polyimide), surface finishes (ENIG, HASL, immersion silver), and trace/space tolerances (down to 3/3 mil). For high-speed or RF applications, confirm impedance control accuracy within ±5% and adherence to IPC-6012 Class 2/3 standards. Suppliers should provide full DFM feedback and Gerber validation prior to fabrication.

Quality Assurance Systems

Prioritize partners with documented quality management systems compliant with ISO 9001:2015. For regulated industries (medical, automotive, aerospace), ensure alignment with IATF 16949, AS9100, or ISO 13485 where applicable. RoHS and REACH compliance must be verifiable via material declarations and batch-specific test reports. In-circuit testing (ICT), flying probe, and X-ray inspection for BGA assemblies should be standard offerings.

Production Scalability & Responsiveness

Assess capacity through measurable indicators:

- Facility size and SMT line count (minimum 2–3 lines for scalable output)

- Monthly production capacity exceeding 50,000 units for mid-tier suppliers

- On-time delivery performance (target ≥98%) and average response time (≤5 hours preferred)

- Reorder rate as an indicator of customer retention and service consistency

Cross-reference self-reported metrics with transaction histories and third-party verification where available.

Customization and Prototyping Support

Leading suppliers offer end-to-end customization—from schematic design and layout to component sourcing and functional testing. Confirm availability of turnkey PCBA services, reverse engineering, and cloning capabilities. Minimum order quantities (MOQ) typically start at 1 piece for prototypes, scaling to 10–100+ units for cost-effective production. Flexible packaging, labeling, and branding options should also be available upon request.

What Are the Best Advanced Circuit PCB Suppliers?

| Company Name | Location | Verified Supplier Type | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Wanfeng Technology Co., Ltd. | Shenzhen, CN | Custom Manufacturer | PCBA, Rigid-Flex, Turnkey Assembly | 100% | ≤1h | US $420,000+ | 66% | Color, material, size, logo, packaging, label, graphic |

| Guangdong Global Well Electronic Limited | Guangdong, CN | - | Multilayer PCB, HDI, Flex, Connectors | 100% | ≤5h | US $60,000+ | 33% | Not specified |

| Shenzhen UC Industrail Limited | Shenzhen, CN | Multispecialty Supplier | Rigid-Flex, OEM, Multilayer | 100% | ≤4h | US $160,000+ | 47% | Color, PCB clone, reverse engineering, packaging, label, material, size, design, Gerber, firmware, graphic |

| Shenzhen Linghangda Technology Co., Ltd. | Shenzhen, CN | Multispecialty Supplier | Custom PCB, Circuit Design Services | 100% | ≤9h | US $3,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

| Guangzhou Leizzi Electronic Technology Co., Ltd. | Guangzhou, CN | - | High Frequency, HDI, Rigid-Flex, Multilayer | 100% | ≤3h | - | - | Not specified |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and customization depth, with Shenzhen Wanfeng leading in reorder rate (66%) and sub-one-hour response times, indicating strong customer satisfaction and operational efficiency. Guangzhou Leizzi demonstrates specialization in high-frequency and HDI boards, catering to telecom and industrial sectors requiring precision impedance control. While Shenzhen UC Industrail offers the broadest customization scope—including reverse engineering and firmware integration—it maintains a moderate reorder rate, suggesting potential gaps in post-sale support or consistency.

All listed suppliers report 100% on-time delivery, though revenue tiers vary significantly—from under $5K to over $400K—reflecting differences in scale and market reach. Buyers seeking high-volume turnkey solutions should prioritize suppliers with proven experience in full PCBA, component sourcing, and functional testing. For niche applications (e.g., flex-rigid stacking or RF design), validate technical expertise through sample reviews and design-for-manufacturability consultations.

FAQs

How to verify advanced circuit PCB supplier reliability?

Cross-check ISO 9001 certification status and request copies of material compliance documentation (RoHS, REACH). Evaluate supplier credibility through verified transaction history, response consistency, and customer reviews focused on defect rates and communication transparency. Video audits of production floors can confirm equipment sophistication and workflow organization.

What is the typical lead time for custom PCB orders?

Prototype lead times average 5–7 days for 2–6 layer boards. Complex multilayer or HDI designs may require 10–14 days. Mass production timelines range from 12–18 days, excluding shipping. Express services (3–5 days) are available at premium rates from select suppliers.

Do suppliers support small-batch or single-piece orders?

Yes, most suppliers accept MOQs as low as 1 piece for prototyping and small-scale testing. Unit pricing decreases significantly at volumes above 100 units, especially for standardized stack-ups and materials.

Can suppliers handle complete PCBA with component sourcing?

Many offer turnkey assembly services, managing BOM procurement, solder paste application, pick-and-place, reflow, AOI, and testing. Confirm whether they maintain approved vendor lists (AVLs) for critical components and have inventory management protocols to mitigate part shortages.

What file formats are required for submission?

Standard deliverables include Gerber files (RS-274X), drill files, netlists, and centroid data. For DFM checks, suppliers may also request schematic diagrams and 3D STEP models. Some support direct EDA tool exports (Altium, KiCad, Eagle).