Alignment Machine Producer

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

1/10

1/10

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/18

1/18

1/28

1/28

1/3

1/3

1/21

1/21

About alignment machine producer

Where to Find Alignment Machine Producers?

China remains the global epicenter for alignment machine manufacturing, with key production hubs concentrated in industrial provinces such as Liaoning, Guangdong, and Shanghai. These regions host vertically integrated facilities capable of full-cycle production—from structural fabrication and electronic integration to software calibration—enabling rapid scaling and cost efficiency. Yingkou (Liaoning) and Guangzhou (Guangdong) have emerged as specialized clusters for automotive diagnostic and alignment systems, supported by regional supply chains for sensors, cameras, and precision mechanics.

Suppliers in these zones benefit from proximity to component manufacturers and export logistics networks, reducing material lead times by 15–20% compared to non-specialized regions. The ecosystem supports both standardized and engineered-to-order machines, with typical production cycles ranging from 20–45 days depending on configuration complexity. Buyers gain access to scalable output, with leading producers reporting monthly revenues exceeding US $1.5 million, indicating robust operational capacity and international market penetration.

How to Choose Alignment Machine Producers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Product Range

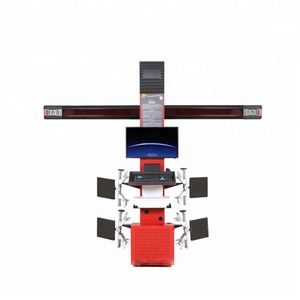

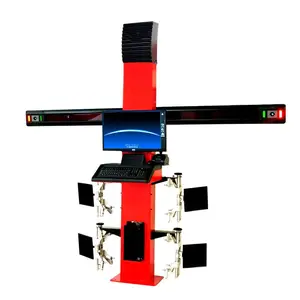

Assess the breadth of product offerings as an indicator of specialization. Leading producers offer 3D, 5D, and CCD-based alignment systems with compatibility across passenger vehicles, trucks, and commercial fleets. Verify inclusion of core components such as high-resolution cameras, target plates, wireless sensors, and OEM-level diagnostic integration. Suppliers listing over 200 units in wheel alignment or related vehicle equipment demonstrate focused expertise and inventory depth.

Quality Assurance and Compliance

While explicit certification data is not provided, performance metrics serve as proxies for quality management. Prioritize suppliers with on-time delivery rates ≥95% and response times ≤3 hours, which correlate with disciplined internal processes. Reorder rates above 25%—as seen with some top-tier suppliers—indicate customer satisfaction and product reliability. For markets requiring regulatory compliance (e.g., CE, ISO 9001), request documentation during due diligence, particularly for integration into certified repair shops.

Customization and After-Sales Support

Evaluate customization capabilities including software language localization, logo branding, packaging design, and hardware modifications (e.g., plug types, sensor configurations). Multiple suppliers confirm options for color, material, size, and ECU tool integration, suggesting flexibility for private labeling and regional adaptation. Confirm availability of technical support, calibration guides, and firmware updates prior to procurement.

Production Capacity and Transaction Metrics

Use online revenue estimates and reorder rates as indicators of scale and stability. Top-performing suppliers report annual online revenues exceeding US $400,000, with reorder rates up to 50%, reflecting strong client retention. Cross-reference this with response time and delivery performance: sub-3-hour responses and 100% on-time delivery suggest efficient order management and dedicated export teams.

What Are the Best Alignment Machine Producers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Response Time | Customization Options |

|---|---|---|---|---|---|---|

| Shanghai AA4C Auto Maintenance Equipment Co., Ltd | Other Vehicle Equipment (255), Car Lifts (181) | US $1,500,000+ | 100% | 15% | ≤3h | Color, material, size, logo, packaging, label, graphic |

| Yingkou Aver Technology Industry Co., Ltd. | Car Lifts (389), Wheel Alignment (229) | US $70,000+ | 87% | <15% | ≤6h | Not specified |

| Guangzhou Carway Auto Equipment Co., Ltd. | Multiple LAUNCH-branded 3D/5D aligners | US $460,000+ | 95% | 17% | ≤2h | Color, material, size, ECU tools, immobilizer, diagnostic tools, logo, language, packaging, plug, label, graphic |

| Yingkou Yiming Machinery Equipment Co., Ltd. | Wheel Alignment Machines (varied pricing tiers) | US $120,000+ | 100% | 27% | ≤3h | Color, material, size, logo, packaging, label, graphic |

| Yantai TARGET Machinery Co., Ltd. | Spray Booths (2715), Body Repair Equipment (1797) | US $10,000+ | 100% | 50% | ≤2h | Not specified |

Performance Analysis

Shanghai AA4C leads in revenue scale (US $1.5M+), suggesting extensive distribution networks and diversified product lines, though its 15% reorder rate indicates room for improvement in customer retention. Guangzhou Carway stands out for technical customization breadth, supporting diagnostics and multilingual interfaces—critical for global service centers. Yingkou Yiming achieves a strong 27% reorder rate with competitive pricing and full customization, signaling effective value positioning. Yantai TARGET, while less focused on alignment machines, demonstrates exceptional loyalty (50% reorder rate), likely driven by bundled solutions in body repair systems. Despite lower revenue, its 100% on-time delivery and rapid response reflect operational discipline.

FAQs

What is the typical MOQ and pricing range for alignment machines?

Minimum order quantities are uniformly set at 1 set across suppliers. Pricing varies significantly by technology: entry-level models start at $228–$370, mid-tier 3D systems range from $1,355–$2,075, while high-precision 5D or truck-specific units reach $4,100–$28,000, reflecting sensor count, software sophistication, and vehicle compatibility.

How long do production and shipping take?

Standard production lead time is 20–30 days post-order confirmation. Shipping via sea freight adds 25–40 days for international destinations. Air freight reduces transit to 5–10 days but increases costs proportionally, typically reserved for samples or urgent replacements.

Can suppliers provide customized software or branding?

Yes, multiple suppliers offer interface language localization, logo embedding, and branded packaging. Advanced providers support integration with diagnostic tools and immobilizer systems, enabling seamless adoption in franchise repair networks.

Are samples available before bulk ordering?

Sample policies vary; most suppliers allow sample purchases at standard pricing. Some may apply sample fees toward initial orders. Expect 15–25 days for sample production, depending on customization level.

What are key considerations for quality verification?

Request factory audit reports or video tours to verify production lines and quality control checkpoints. Insist on pre-shipment inspections for critical parameters: camera alignment accuracy, software responsiveness, and mechanical durability. Third-party inspection services can validate performance against industry benchmarks prior to shipment release.