Api Micronization

1/30

1/30

CN

CN

1/18

1/18

CN

CN

1/28

1/28

CN

CN

1/26

1/26

1/22

1/22

1/17

1/17

1/15

1/15

1/13

1/13

About api micronization

Where to Find API Micronization Equipment Suppliers?

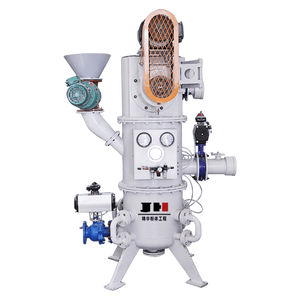

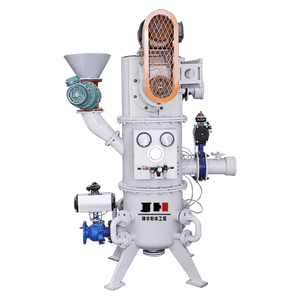

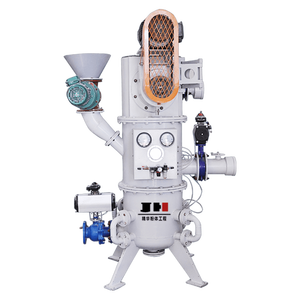

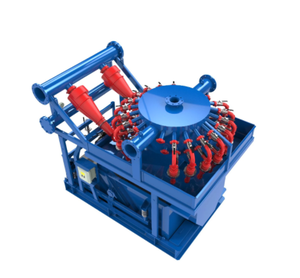

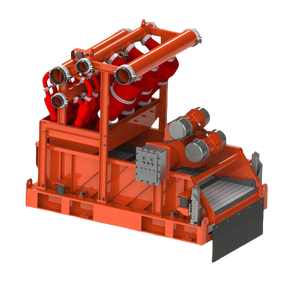

China is a leading manufacturing hub for precision micronization equipment used in active pharmaceutical ingredient (API) processing, with key industrial clusters concentrated in Shandong and Henan provinces. These regions host specialized engineering firms that integrate advanced milling technologies—such as fluidized bed jet milling, cryogenic grinding, and air micronizing systems—into scalable production platforms. Shandong’s strong foundation in chemical machinery and material science supports high-precision particle size reduction critical for API bioavailability, while Henan’s dense network of powder processing specialists enables cost-efficient innovation cycles.

The regional ecosystems offer vertically integrated supply chains, allowing manufacturers to control raw material sourcing, CNC machining, assembly, and performance testing under one roof. This integration reduces lead times for standard systems to 45–60 days and supports rapid prototyping for customized solutions. Buyers benefit from localized access to technical talent, metallurgical suppliers, and quality assurance labs within a 50-kilometer radius, contributing to 20–30% lower total procurement costs compared to Western equivalents. Additionally, many suppliers report online transaction volumes exceeding $190,000 annually, indicating established export readiness and digital engagement capacity.

How to Choose API Micronization Equipment Suppliers?

Selecting reliable partners requires rigorous evaluation across three core dimensions:

Technical Capability Validation

Confirm expertise in API-specific micronization techniques, including jet milling, cryogenic pulverizing, and multi-stage classification systems capable of achieving D97 particle sizes below 10 microns. Evaluate whether the supplier offers process validation documentation, such as airflow dynamics modeling or laser diffraction analysis reports. For compliance-sensitive markets, CE marking or adherence to GMP (Good Manufacturing Practice) standards should be verified through official records.

Production Infrastructure Assessment

Prioritize suppliers with dedicated R&D capabilities and comprehensive in-house manufacturing facilities. Key indicators include:

- Minimum factory area exceeding 3,000m² to support full-scale production

- In-house design and engineering teams focused on powder dynamics and pneumatic conveying systems

- CNC fabrication, welding, and surface finishing capabilities

Cross-reference facility scale with on-time delivery performance; suppliers maintaining ≥99% punctuality typically demonstrate robust workflow management.

Quality & Transaction Assurance

Require documented quality control protocols covering material traceability, pressure testing, and cleanliness standards for pharmaceutical applications. Favor suppliers offering third-party inspection options and secure payment terms via trade assurance mechanisms. Request sample units to validate particle size distribution, energy consumption, and operational noise levels before scaling procurement.

What Are the Best API Micronization Equipment Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Customization | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shandong Alpa Powder Technology Co., Ltd. | Shandong, CN | Grinding Equipment, Mine Mill, Crusher | US $190,000+ | 100% | ≤8h | No | 3 products | $20,000–90,000 |

| Weifang Jinghua Powder Technology Co., Ltd. | Shandong, CN | Grinding Equipment, Air Jet Mill, Crusher | Not disclosed | 100% | ≤2h | No | 4 products | $23,500–58,000 |

| Xinxiang Lvda Purification Equipment Corporation | Henan, CN | Hydraulic Oil Filters, Filtration Elements | US $630,000+ | 99% | ≤2h | Yes | 3 products | $30–55 |

| Henan Hqfiltration Equipment Manufacturing Co., Ltd. | Henan, CN | Filtration Elements, API Filter Components | US $5,000+ | 80% | ≤3h | Yes | 4 products | $20–50 |

| Zhangjiagang Huibang Machinery Co., Ltd. | Jiangsu, CN | Automatic Mills, Plastic Grinding Systems | Not disclosed | 100% | ≤5h | Yes | 3 products | $7,800–25,000 |

Performance Analysis

Shandong-based suppliers like Alpa and Jinghua specialize in turnkey micronization systems, offering high-value jet mills and cryogenic pulverizers tailored for API applications, with prices reflecting advanced engineering and scalability. Both maintain perfect on-time delivery records, though response times vary significantly—Jinghua leads with sub-2-hour responsiveness, enhancing buyer communication efficiency. In contrast, Henan’s filtration-focused manufacturers (Lvda, Hqfiltration) provide lower-cost component-level solutions, primarily serving auxiliary roles in micronization workflows. While they offer customization and faster response times, their 80–99% delivery rates suggest potential logistical constraints. Zhangjiagang Huibang presents an entry-level option with compact grinding systems at competitive pricing, suitable for small-scale or pilot-line operations. Buyers seeking full-process integration should prioritize suppliers with proven experience in pharmaceutical-grade environments and validated system performance metrics.

FAQs

How to verify API micronization equipment supplier reliability?

Validate technical claims through site audits or virtual factory tours. Request certifications related to ISO 9001, CE, or GMP compliance. Review transaction histories, customer feedback, and dispute resolution records where available. Independent testing of delivered units against specified particle size distributions (e.g., D50, D97) is recommended prior to full deployment.

What is the typical lead time for micronization systems?

Standard configurations generally require 45–60 days for production and testing. Custom-engineered systems may take 75–90 days depending on complexity. Shipping via sea freight adds 20–35 days for international destinations.

Do suppliers support customization for API processing requirements?

Yes, select manufacturers offer tailored solutions including inert gas circulation, explosion-proof designs, ultra-low temperature operation, and integrated classification systems. Customization availability should be confirmed during initial technical consultations.

What are common MOQ and pricing structures?

Most suppliers set a minimum order quantity of 1 set for complete machines, with prices ranging from $7,800 for basic models to over $90,000 for high-capacity cryogenic systems. Component suppliers often require only 1–5 pieces per order, priced between $20–$55 per unit.

Can suppliers handle global shipping and import compliance?

Established exporters manage international logistics, offering FOB or CIF terms. Buyers must confirm equipment conformity with destination-country electrical, safety, and pharmaceutical manufacturing regulations to ensure smooth customs clearance.