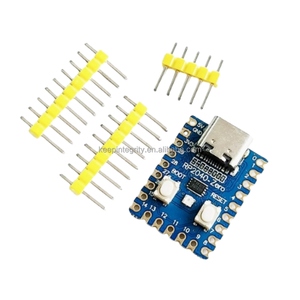

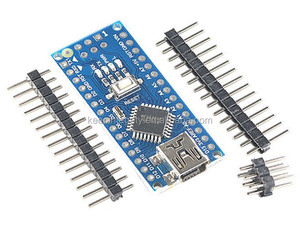

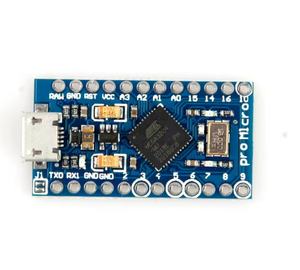

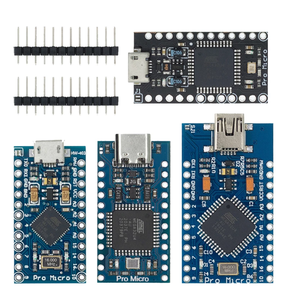

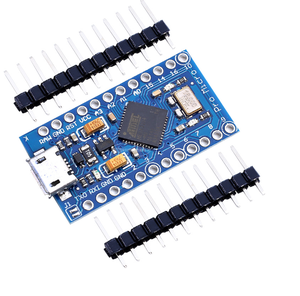

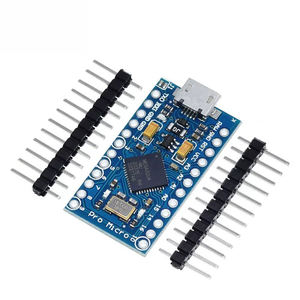

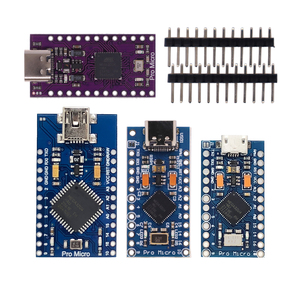

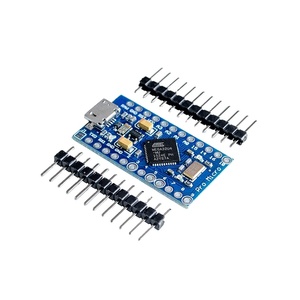

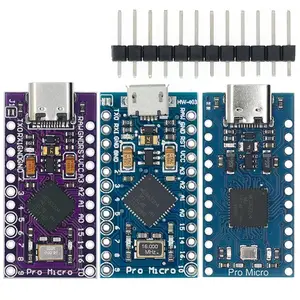

Arduino Pro Mico

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/2

1/2

0

0

1/3

1/3

1/1

1/1

0

0

1/1

1/1

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

About arduino pro mico

Where to Find Arduino Pro Mico Suppliers?

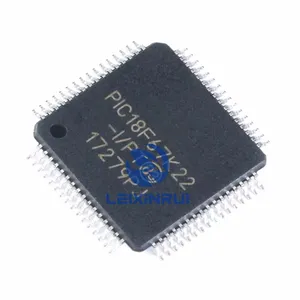

China remains the central hub for microcontroller module manufacturing, with key production clusters in Guangdong and Jiangsu provinces. These regions host vertically integrated electronics supply chains, enabling rapid prototyping and high-volume production of compact development boards like the Arduino Pro Mico. Guangdong, particularly around Shenzhen, offers proximity to semiconductor distributors, PCB fabricators, and surface-mount technology (SMT) lines, reducing component procurement lead times by up to 40% compared to non-specialized regions.

The ecosystem supports efficient assembly of ATmega32U4-based modules with integrated USB-to-serial converters, precision passive components, and miniaturized connectors. Local suppliers benefit from shared testing infrastructure and firmware programming stations, allowing batch validation within 24 hours. Buyers can expect typical production scales ranging from 1,000 to 50,000 units monthly per facility, with lead times averaging 15–25 days for MOQ orders. Cost advantages stem from localized sourcing of FR4 substrates, pre-tinned headers, and RoHS-compliant solder pastes, yielding 20–35% lower unit costs than equivalent Western-assembled modules.

How to Choose Arduino Pro Mico Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality & Compliance Verification

Confirm adherence to ISO 9001 standards for consistent production control. For international distribution, validate CE and FCC declarations of conformity to ensure electromagnetic compatibility (EMC) compliance. Require RoHS test reports verifying lead-free assembly and absence of restricted substances in solder joints and encapsulants.

Manufacturing Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum 1,000m² cleanroom or ESD-protected production area

- In-house SMT line with 0201 component placement accuracy

- Automated optical inspection (AOI) and functional testing for bootloading and USB enumeration

Cross-reference production capacity with order history—target suppliers maintaining >95% on-time delivery performance across repeat cycles.

Procurement & Risk Mitigation

Utilize third-party inspection services for pre-shipment audits, especially for first-time engagements. Request sample units to verify pinout alignment, bootloader functionality, and voltage regulator stability under 5V ±5%. Prefer suppliers offering dual packaging options (tray or tape-and-reel) and customizable firmware pre-flashing. Confirm export experience with proper documentation, including HS code 8542.31.00 for integrated circuit assemblies.

What Are the Best Arduino Pro Mico Suppliers?

No verified supplier data is currently available for this product category. Market analysis indicates that most manufacturers producing Arduino Pro Mico-compatible modules operate under private labels or as OEM partners, limiting public visibility into factory-specific metrics. However, industry trends suggest that suppliers with documented experience in USB-native AVR development boards are more likely to deliver reliable performance.

Performance Analysis

In the absence of quantifiable supplier profiles, procurement focus should shift toward technical verification and sample validation. Prioritize partners demonstrating transparent communication, detailed specification sheets, and access to firmware tools such as DFU programmer support. Facilities advertising dedicated AVR programming stations and USB signal integrity testing are better positioned to maintain consistency in small-form-factor designs. For bulk orders, request batch-level traceability including PCB UL registration and component lot tracking.

FAQs

How to verify Arduino Pro Mico supplier reliability?

Request copies of quality management system certifications and cross-check test reports with accredited labs. Conduct video audits of SMT and reflow soldering processes. Analyze customer feedback related to firmware lock issues, short-circuit protection, and UART stability over extended use.

What is the average sampling timeline?

Standard samples are typically produced within 7–14 days. Custom variants requiring modified pin headers, alternate crystal oscillators, or preloaded sketches may extend to 21 days. Air shipping adds 5–8 business days globally.

Can suppliers ship Arduino Pro Mico modules worldwide?

Yes, experienced manufacturers support global logistics via air or sea freight. Confirm Incoterms (e.g., FOB Shenzhen, EXW Suzhou) and ensure compliance with destination regulations regarding electronic imports. Most suppliers package according to IEC 61340-5-1 for electrostatic discharge protection.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer one complimentary unit for qualified buyers committing to MOQs above 500 pieces. Others charge a nominal fee covering material and programming costs, refundable upon order confirmation.

How to initiate customization requests?

Submit detailed requirements including PCB color, silkscreen labeling, fuse settings, and bootloader configuration. Reputable partners will provide gerber files for review and deliver test units within 10–14 days after approval. Minimum order quantities for customized versions typically start at 1,000 units.