Arduino Sensors Manufacturer

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/1

1/1

0

0

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/15

1/15

1/2

1/2

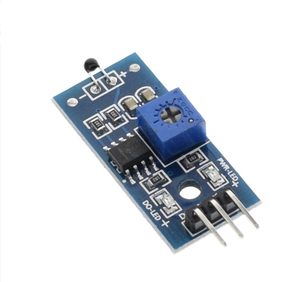

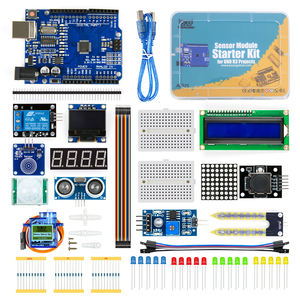

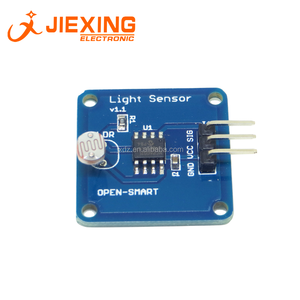

About arduino sensors manufacturer

Where to Find Arduino Sensors Manufacturers?

China leads global production of Arduino-compatible sensors, with manufacturing hubs concentrated in Guangdong and Jiangsu provinces. Shenzhen, within Guangdong, hosts over 70% of China’s electronics component suppliers, supported by a mature ecosystem of PCB fabricators, firmware developers, and rapid prototyping services. This cluster enables agile development cycles and efficient scaling from prototype to mass production. Jiangsu’s Suzhou and Wuxi zones specialize in precision sensor modules, leveraging proximity to semiconductor fabs and automated SMT lines that reduce assembly costs by 18–22% compared to non-specialized regions.

These industrial clusters offer vertical integration across design, surface-mount technology (SMT), testing, and packaging stages. Suppliers benefit from localized access to raw materials—such as MEMS chips, resistive elements, and environmental sensing substrates—and streamlined logistics via Hong Kong and Shanghai ports. Buyers gain advantages including lead times averaging 25–35 days for batch orders, 20–30% lower unit costs due to economies of scale, and flexibility for low-volume customizations. Most manufacturers support MOQs ranging from 100 to 500 units, with scalability to 50,000+ units monthly for established partners.

How to Choose Arduino Sensors Manufacturers?

Implement rigorous evaluation criteria when selecting manufacturing partners:

Quality & Compliance Standards

Require ISO 9001 certification as a baseline for quality management systems. For export to EU and North American markets, confirm RoHS and CE compliance to meet environmental and electromagnetic compatibility regulations. Verify test reports for sensor accuracy, thermal stability, and long-term drift performance—particularly critical for environmental, motion, and gas detection modules.

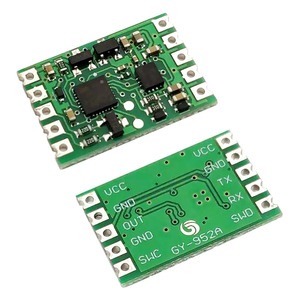

Technical & Production Capacity

Assess core capabilities through the following benchmarks:

- Minimum 2,000m² facility with ESD-protected SMT and testing zones

- In-house R&D team comprising firmware engineers and circuit designers (≥10% of technical staff)

- Automated production lines featuring pick-and-place machines and AOI (Automated Optical Inspection)

Cross-reference declared output capacity with on-time delivery rates (target ≥97%) and reorder frequency data to validate operational reliability.

Procurement & Transaction Security

Utilize secure payment mechanisms such as third-party escrow until product validation at destination. Review supplier transaction history for dispute resolution patterns and after-sales responsiveness. Pre-shipment sampling is essential—test samples against defined parameters including voltage tolerance (3.3V/5V), I2C/SPI communication integrity, and response time under real-world conditions before full-scale ordering.

What Are the Best Arduino Sensors Manufacturers?

No verified supplier data is currently available for Arduino sensors manufacturers.

Performance Analysis

In the absence of specific supplier profiles, procurement focus should remain on regional strengths and technical vetting protocols. Shenzhen-based manufacturers typically excel in fast-turn prototyping and IoT-integrated sensor development, while Jiangsu producers emphasize high-precision calibration and industrial-grade durability. Prioritize facilities with documented experience in exporting to regulated markets and those offering transparent audit trails—from bill of materials (BOM) sourcing to final functional testing. For customized sensor arrays, require proof of in-house programming and calibration infrastructure via video audits prior to contract finalization.

FAQs

How to verify Arduino sensors manufacturer reliability?

Validate certifications through accredited bodies and request factory audit reports covering production controls, component traceability, and EMI/EMC testing procedures. Analyze customer feedback focused on consistency in signal output, firmware stability, and post-delivery technical support.

What is the average sampling timeline?

Standard sensor samples take 10–18 days to produce. Custom variants requiring unique PCB layouts or firmware modifications may require 25–35 days. Add 5–9 days for international air shipping depending on destination region.

Can manufacturers ship Arduino sensors worldwide?

Yes, most established factories manage global logistics with FOB, CIF, or DDP shipping terms. Confirm compliance with destination import standards for electronic components and ensure proper labeling per HS code 8543.00 for active sensors.

Do suppliers provide free samples?

Sample policies vary. Many manufacturers waive fees for qualified buyers committing to minimum order volumes (typically 500+ units). Otherwise, expect to cover 40–60% of material and programming costs for initial samples.

How to initiate customization requests?

Submit detailed specifications including sensing type (temperature, humidity, motion, etc.), interface protocol (analog, I2C, UART), power requirements, and physical dimensions. Leading suppliers respond with schematic drafts within 48 hours and deliver functional prototypes within 3–4 weeks.