Automatic Pcb Assembly Machine

Top sponsor listing

Top sponsor listing

CN

CN

About automatic pcb assembly machine

Where to Find Automatic PCB Assembly Machine Suppliers?

China remains the global epicenter for automatic PCB assembly machine manufacturing, with key industrial clusters concentrated in Guangdong and Zhejiang provinces. Shenzhen and Guangzhou in Guangdong province host advanced electronics production ecosystems, offering integrated access to component suppliers, automation engineers, and export logistics networks. These regions support rapid prototyping and scalable production of surface mount technology (SMT) equipment, including pick-and-place machines, stencil printers, and selective coating systems.

The supply chain benefits from localized manufacturing synergies—over 70% of listed suppliers operate facilities within 50km of major electronic component distribution hubs, reducing material lead times by 20–30%. Buyers gain access to vertically integrated capabilities covering machine design, CNC fabrication, PLC control integration, and final testing. Typical advantages include MOQ flexibility (from single units to full SMT lines), customization options for nozzle configurations and vision systems, and competitive pricing driven by mature supplier competition.

How to Choose Automatic PCB Assembly Machine Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical safety compliance. For automated precision machinery, confirm performance metrics including placement accuracy (±0.025mm or better), component range (0201 to large ICs), and throughput (CPH rates). Request test reports on critical subsystems like motor drivers, conveyor alignment, and optical recognition calibration.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum facility size of 2,000m² for dedicated assembly and testing zones

- In-house engineering teams capable of customizing feeder layouts, vision algorithms, or software interfaces

- Integration capabilities for full-line solutions (printer + mounter + reflow + AOI)

- Cross-reference online revenue indicators and on-time delivery records (>90% recommended)

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services until post-delivery acceptance testing is completed. Prioritize suppliers with documented after-sales support, including remote diagnostics, spare parts availability, and technician training. Conduct sample validation to benchmark machine stability, error rate under continuous operation, and ease of changeover between PCB models.

What Are the Best Automatic PCB Assembly Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Guangzhou Minder-Hightech Co., Ltd. | Guangdong, CN | Electronics Production Machinery (503) | 50% | ≤5h | 80% | US $270,000+ | Color, material, logo, packaging, label, graphic |

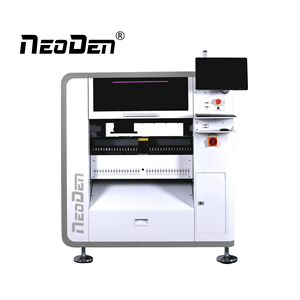

| Wenzhou Zhengbang Electronic Equipment Co., Ltd. | Zhejiang, CN | SMT Line, Pick-and-Place Machines | 94% | ≤2h | <15% | US $140,000+ | Full SMT line, PCB design, nozzles, capacitor setup |

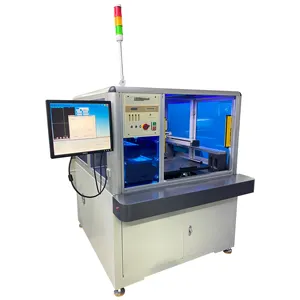

| Shenzhen Censtar Technology Co., Ltd. | Guangdong, CN | Electronics Production Machinery (65) | 100% | ≤1h | - | - | Coating machines, magazine systems, high-speed mounts |

| GOLDLAND ELECTRONIC TECHNOLOGY CO., LIMITED | Guangdong, CN | Electronic Products Machinery (436) | 100% | ≤2h | 25% | US $9,000+ | Used/refurbished OEM equipment integration |

| Shenzhen Liyang Welding Equipment Co., Ltd. | Guangdong, CN | Other Machinery & Industrial Equipment (427) | 91% | ≤8h | <15% | US $60,000+ | Vision system upgrades, desktop automation |

Performance Analysis

Shenzhen Censtar and GOLDLAND demonstrate perfect on-time delivery performance, indicating strong production planning and logistics execution. Wenzhou Zhengbang stands out with sub-2-hour average response time and extensive customization capacity for full SMT lines, making it suitable for buyers requiring tailored integration. Guangzhou Minder-Hightech reports an unusually high reorder rate (80%), suggesting robust customer retention despite moderate delivery reliability. Buyers seeking refurbished or OEM-compatible systems may consider GOLDLAND’s offerings, which include legacy Yamaha and DEK models at reduced price points ($8,000–$18,000 range).

FAQs

How to verify automatic PCB assembly machine supplier reliability?

Cross-check claimed certifications (ISO, CE) through official databases. Request factory audit reports or video walkthroughs showing CNC machining centers, calibration labs, and final assembly processes. Analyze transaction history for consistency in order fulfillment and responsiveness.

What is the typical lead time for standard and customized machines?

Standard pick-and-place units ship within 15–30 days. Customized configurations involving specialized feeders, vision systems, or software modifications require 35–50 days. Refurbished equipment may be available for immediate shipment.

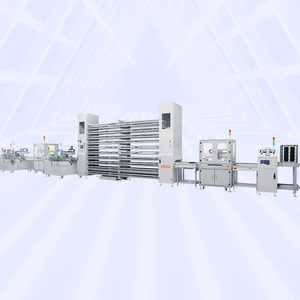

Can suppliers provide full SMT production lines?

Yes, leading suppliers offer integrated solutions encompassing stencil printers, automated optical inspection (AOI), reflow ovens, and conveyors. Confirm compatibility between components and request layout simulations for floor space optimization.

Do manufacturers support after-sales service and training?

Most suppliers provide basic remote troubleshooting and instructional documentation. Advanced support—including on-site technician visits, firmware updates, and operator training—is typically offered under extended service agreements.

What are common customization options for PCB assembly machines?

Buyers can modify feeder types (tape, stick, tray), nozzle sets for passive/active components, vision camera resolution, conveyor width, and software interface language. Some suppliers also support PLC programming adjustments and IoT-enabled monitoring integration.