Automobile Assembly Line Process

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

1/10

1/10

1/18

1/18

CN

CN

1/21

1/21

1/30

1/30

CN

CN

CN

CN

1/18

1/18

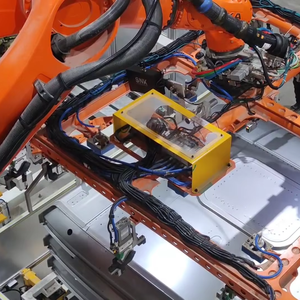

About automobile assembly line process

Where to Find Automobile Assembly Line Process Suppliers?

China remains the global epicenter for automobile assembly line equipment manufacturing, with key industrial clusters in Shandong and Zhejiang provinces driving innovation and cost efficiency. Shandong’s Jinan and Qingdao regions specialize in laser-cutting-integrated production systems, leveraging proximity to steel suppliers to reduce material costs by 15–20%. Meanwhile, Zhejiang’s Hangzhou-Ningbo corridor hosts automation-focused manufacturers equipped with advanced conveyor and robotic integration capabilities, serving both internal combustion and electric vehicle (EV) producers.

These hubs offer vertically integrated ecosystems where design, fabrication, and testing occur within consolidated facilities. This integration enables lead times of 45–60 days for standard automated lines, with modular designs allowing rapid reconfiguration for new vehicle models. Buyers benefit from localized access to CNC machining, welding automation, and control system engineering, reducing dependency on external component sourcing. The region’s mature logistics infrastructure supports efficient export operations, particularly for bulk shipments via sea freight.

How to Choose Automobile Assembly Line Process Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Engineering Capabilities

Verify suppliers possess in-house design teams capable of delivering turnkey solutions, including PLC programming, robotics integration, and factory layout planning. For EV battery pack and powertrain lines, confirm experience with cleanroom-compatible conveyors and precision torque control systems. Request validation of compliance with ISO 9001 and CE standards—mandatory for European market deployment.

Production Infrastructure Assessment

Evaluate core operational metrics:

- Minimum facility size of 5,000m² to support full-line assembly and testing

- In-house capabilities in CNC machining, welding, and electrical cabinet fabrication

- Demonstrated project execution for complete plant layouts or SKD (Semi-Knocked Down) systems

Cross-reference delivery performance data: prioritize suppliers with ≥95% on-time shipment rates and documented scalability for multi-line installations.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services tied to milestone inspections. Demand detailed technical documentation—including P&ID diagrams, safety interlock schematics, and maintenance protocols—before finalizing contracts. Conduct pre-shipment audits either onsite or via live video walk-throughs to verify build quality and component authenticity. Pilot testing of critical subsystems (e.g., motorized roller conveyors or AGV interfaces) is recommended prior to full deployment.

What Are the Best Automobile Assembly Line Process Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (Min. Order) | Verified Expertise |

|---|---|---|---|---|---|---|---|

| Shandong Huiyao Laser Technology Co., Ltd. | Shandong, CN | EV Battery Pack Lines, Lithium-Ion Production Systems | 66% | ≤2h | <15% | $250,000–450,000 (1 set) | Multispecialty Supplier |

| Zhejiang Jianggong Automation Equipment Co., Ltd. | Zhejiang, CN | Conveyor Lines, Engine Assembly Systems | 100% | ≤17h | <15% | $1,999–$100,000 (1 meter/unit) | Assembly Line Specialist |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Automotive Plant Layouts, Full Automatic Lines | 100% | ≤8h | - | $46,350–$256,000 (1 set) | Integrated Line Solutions |

| Zhejiang Jiunuo Auto Air Condition Co., Ltd. | Zhejiang, CN | AC Hose Assemblies for Assembly Lines | 100% | ≤8h | <15% | $5–$11.45 (100 pieces) | Component-Level Supply |

Performance Analysis

Zhejiang Jianggong and Zhengzhou Duoyuan demonstrate strong reliability with 100% on-time delivery records, indicating robust production scheduling despite limited public revenue data. Shandong Huiyao targets high-value EV battery line projects with average pricing above $250,000 per system, though its lower reorder rate suggests room for improvement in post-sale support or customization alignment. Duoyuan offers broad scope—from individual workstations to full plant automation—with transparent pricing across multiple configurations. Zhejiang Jiunuo serves niche component needs within HVAC integration stages of final assembly, providing low-cost, high-volume parts essential for serial production continuity.

FAQs

What certifications should automobile assembly line suppliers have?

Essential certifications include ISO 9001 for quality management and CE marking for conformity with European health, safety, and environmental standards. For exports to North America, UL or CSA compliance may be required for electrical control systems. Suppliers should provide test reports for safety circuits, emergency stops, and EMI shielding.

What is the typical lead time for a custom automobile assembly line?

Custom line fabrication typically takes 60–90 days from design approval to readiness for shipment. Standardized conveyor or workstation modules can be delivered in 45 days. Add 10–14 days for international shipping via container freight.

Can suppliers handle full factory automation projects?

Yes, leading providers like Zhengzhou Duoyuan and Shandong Huiyao offer end-to-end services including process flow design, workstation ergonomics, automation integration, and commissioning support. These suppliers often collaborate with robotics integrators and MES software vendors to deliver smart factory-ready systems.

Is customization available for EV-specific production lines?

Most top-tier suppliers support EV-specific requirements such as battery module handling, high-voltage sealing stations, and thermal runaway testing integration. Custom tooling, non-magnetic materials, and explosion-proof components are commonly offered upon request.

How to assess supplier responsiveness and technical clarity?

Evaluate response speed (target ≤8 hours), technical depth in replies, and willingness to provide CAD models or 3D renderings. High-performing suppliers typically assign dedicated engineers to buyer inquiries and proactively clarify specifications before quoting.