Automotive Assembly Line Automation

CN

CN

CN

CN

CN

CN

CN

CN

About automotive assembly line automation

Where to Find Automotive Assembly Line Automation Suppliers?

China remains the global epicenter for automotive assembly line automation manufacturing, with key industrial clusters in Zhengzhou and Shanghai driving innovation and scale. Zhengzhou's advanced equipment zone hosts integrated suppliers specializing in full-line solutions—from conveyor systems to robotic welding cells—leveraging regional advantages in machinery R&D and logistics connectivity. Shanghai’s precision engineering ecosystem supports high-complexity automation components, including programmable fixtures and modular conveyors, benefiting from proximity to Tier 1 automotive OEMs and Tier 2 suppliers.

These hubs feature vertically aligned supply chains enabling rapid prototyping and deployment. Suppliers typically operate facilities exceeding 5,000m² with in-house design, fabrication, and testing capabilities, reducing dependency on external vendors. Buyers benefit from compressed lead times (average 45–60 days for custom lines), cost efficiencies (20–35% below Western benchmarks), and scalable production models accommodating both pilot projects and mass deployment. The concentration of technical talent and component manufacturers within 50km radii further enhances coordination and after-sales responsiveness.

How to Choose Automotive Assembly Line Automation Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for EU market compliance. For safety-critical systems like robotic welding or battery pack assembly, confirm electrical and mechanical certifications (e.g., IEC, UL) are current and applicable. Request test reports for load capacity, cycle durability, and control system reliability, particularly for conveyor belts and automated guided vehicles (AGVs).

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum factory area of 3,000m² to support full-line integration

- In-house engineering teams capable of system design, PLC programming, and robotics integration

- On-site machining, welding, and assembly capabilities for rapid iteration

Cross-reference declared capacities with verified delivery performance. Prioritize suppliers reporting ≥97% on-time fulfillment and response times under 8 hours.

Customization & Transaction Security

Confirm customization scope—including layout adaptation, speed calibration, and interface compatibility with existing MES/SCADA systems. Use secure payment mechanisms such as escrow services until site commissioning is verified. Analyze reorder rates and online transaction volume as proxies for customer satisfaction and financial stability. Pre-shipment inspection and third-party audits are recommended for orders exceeding $50,000.

What Are the Best Automotive Assembly Line Automation Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou E.p Machinery Co., Ltd. | Zhengzhou, CN | Motorcycle/ATV Assembly Lines | $360–595/meter | 1–10 meters | 100% | ≤6h | US $70,000+ | - |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Zhengzhou, CN | Car/Van Production Lines, Welding Systems | $45,000–256,800/set | 1 set | 100% | ≤8h | - | - |

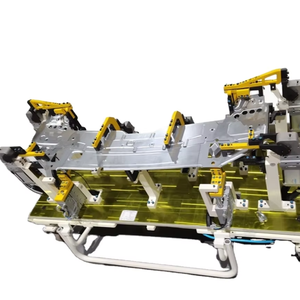

| Shanghai Qiongkuo Intelligent Equipment Co., Ltd. | Shanghai, CN | Robotic Fixtures, Welding Clamps, System Design | $6,000–10,000/set | 1 set | 100% | ≤8h | - | - |

| Shanghai Detall Electronics Technology Co., Ltd. | Shanghai, CN | Conveyor Belts, Workbenches, Chain Lines | $1,100–2,600/set | 1 set | 100% | ≤2h | US $20,000+ | <15% |

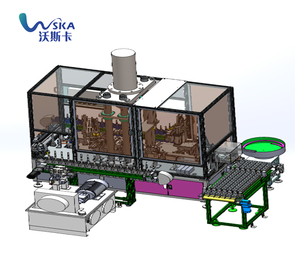

| Guangzhou Sanhok Hitech Co., Ltd. | Guangzhou, CN | Battery Pack Assembly, Custom Conveyors | $700–49,000/unit | 1 piece/set | 100% | ≤5h | US $220,000+ | 50% |

Performance Analysis

Zhengzhou-based suppliers dominate large-scale line supply, offering complete turnkey solutions for motorcycle and passenger vehicle production at competitive pricing. Duoyuan and E.p Machinery provide full-line automation packages with prices starting at $45,000, suitable for mid-tier manufacturers seeking entry-level automation. In contrast, Shanghai Qiongkuo focuses on precision tooling and robotic integration, serving clients requiring high-accuracy welding and clamping systems. Detall Electronics delivers cost-effective conveyor subsystems ideal for partial automation upgrades. Guangzhou Sanhok stands out with a 50% reorder rate and extensive customization options, indicating strong client retention and flexibility in material, color, and configuration. All listed suppliers maintain 100% on-time delivery, but response efficiency varies—prioritize those with sub-5-hour average replies for time-sensitive projects.

FAQs

How to verify automotive assembly line automation supplier reliability?

Cross-check ISO and CE certifications with issuing bodies. Request facility videos demonstrating active production lines and control systems. Review transaction histories for consistent order volume and dispute resolution records. Validate technical claims through reference projects or third-party audit reports.

What is the typical lead time for custom assembly lines?

Standard configurations require 30–45 days. Fully customized lines involving robotics, vision systems, or specialized conveyors take 60–90 days, depending on complexity. Add 10–15 days for international shipping via sea freight.

Do suppliers offer design and installation support?

Yes, most established suppliers provide layout planning, 3D modeling, and remote debugging. On-site commissioning and training may incur additional fees. Confirm service inclusion before contract finalization.

Can automation systems integrate with existing factory networks?

Reputable suppliers design systems with standard communication protocols (e.g., Modbus, Profibus, EtherCAT) for seamless integration into MES, SCADA, or ERP platforms. Provide your network specifications early in discussions to ensure compatibility.

What are common customization options?

Key configurable parameters include conveyor width/speed, load capacity, motor power source (AC/DC), frame material (carbon steel/stainless steel), and control panel language/interface. Suppliers also offer branding elements such as logo printing and color coding.