Background Position

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/17

1/17

1/15

1/15

1/17

1/17

0

0

1/3

1/3

1/12

1/12

1/3

1/3

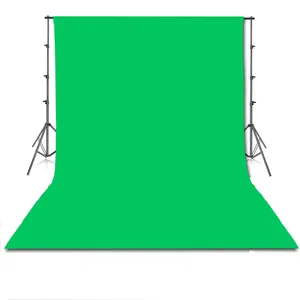

About background position

Where to Find Background Position Suppliers?

China leads global production of background position systems, with key manufacturing clusters in Zhejiang and Guangdong provinces. These regions host vertically integrated supply chains specializing in photography support equipment, combining aluminum extrusion, polyester fabrication, and precision engineering. Shaoxing and Guangzhou serve as primary hubs, offering proximity to raw material suppliers and export ports, enabling efficient logistics for international buyers.

The industrial ecosystem supports both mass production and customization, with facilities equipped for CNC machining, anodizing, and automated welding. This integration reduces component lead times by 20–30% compared to fragmented sourcing models. Buyers benefit from consolidated procurement—where stands, crossbars, and backdrop materials are produced under shared quality controls—resulting in consistent product compatibility and faster order fulfillment (average lead time: 15–25 days).

How to Choose Background Position Suppliers?

Evaluate suppliers using the following criteria to ensure reliability and performance:

Production & Engineering Capability

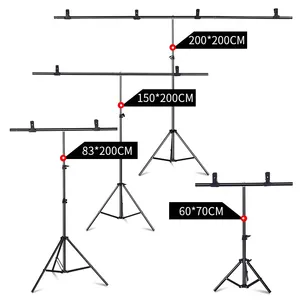

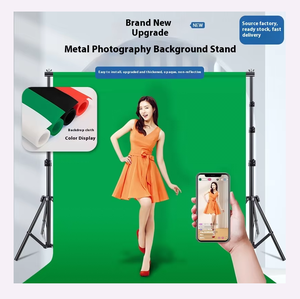

Confirm access to in-house manufacturing infrastructure including aluminum alloy processing lines and fabric cutting/sewing units. Prioritize suppliers with design flexibility for T-shaped, gantry, and multi-axis configurations. Evidence of R&D capacity—such as telescopic crossbar adjustments or motorized lifting mechanisms—indicates potential for custom engineering.

Quality Assurance Metrics

Assess supplier performance through verifiable operational data:

- On-time delivery rate ≥98% indicates strong production planning

- Response time ≤2 hours reflects dedicated customer support

- Reorder rate below 15% suggests stable buyer satisfaction across transaction cycles

Cross-reference these metrics with order volume history (e.g., online revenue exceeding US $10,000+) to validate scalability and market trust.

Transaction Security & Compliance

Require documented quality control processes and packaging standards. While formal certifications (ISO, CE) are not widely listed, prioritize suppliers with structured inspection protocols before shipment. Utilize secure payment methods with milestone verification, especially for customized or high-value orders. Request product samples to evaluate material durability, structural stability, and finish quality prior to bulk procurement.

What Are the Best Background Position Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response Time | Reorder Rate | Online Revenue | Customization |

|---|---|---|---|---|---|---|---|---|

| Shanghai Yingzhi Photography Equipment Co., Ltd. | T-shaped stands, adjustable crossbars, desk backdrops | $3.60–32.40 | 2–15 pieces | 98% | ≤5h | 16% | US $290,000+ | Yes |

| Guangzhou Jingying Information Technology Co., Ltd. | 3-axis manual lifters, aluminum stands, heavy-duty frames | $1–65 | 2 pieces | 98% | ≤2h | <15% | US $40,000+ | Limited |

| Shaoxing Ebuy Gifts Co., Ltd. | Manual and remote-controlled support systems, heavy-duty sets | $1.85–298.50 | 1–2 pieces | 100% | ≤1h | 15% | US $10,000+ | Yes |

| Shaoxing Benniao Photography Equipment Co., Ltd. | Gantry, T-shaped, hand-painted polyester backgrounds | $4.30–11.80 | 1 piece | 96% | ≤3h | <15% | US $1,000+ | No |

| Guangzhou Night Cat Photography Equipment Co., Ltd. | Electric 2–4 axis systems, studio-grade frames | $16–125 | 1–2 pieces | 92% | ≤1h | <15% | US $4,000+ | Yes |

Performance Analysis

Shanghai Yingzhi demonstrates the highest transaction volume and customization capability, making it a strategic partner for buyers requiring tailored solutions at scale. Shaoxing Ebuy stands out with a perfect on-time delivery record and broad pricing tiers, supporting both budget and premium system needs. Guangzhou Night Cat specializes in electric multi-axis systems, targeting professional studios despite a lower delivery rate. Shaoxing Benniao offers the lowest MOQs (1 piece), ideal for sample testing or small setups. Buyers seeking automation should verify motor integration and remote control reliability through pre-shipment inspections.

FAQs

What is the typical MOQ for background position systems?

MOQ varies by supplier and complexity. Basic T-shaped or gantry stands start at 1 piece, while engineered systems (e.g., 3–4 axis lifts) require 2-piece minimums. High-volume suppliers may set MOQs at 6–15 pieces for cost efficiency.

How long does production and shipping take?

Manufacturing lead time averages 15–20 days. Add 7–14 days for international air freight or 25–40 days for sea shipping, depending on destination. Expedited assembly is available from select suppliers for urgent orders.

Can I request custom sizes or branding?

Yes, several suppliers offer dimensional modifications, color finishes, and OEM labeling. Confirm feasibility for telescopic ranges, load capacity, and logo printing before order placement. Custom tooling may incur additional fees and extended timelines.

Are samples available before bulk ordering?

Most suppliers provide samples, typically at full cost. Pricing ranges from $2–$150 depending on model complexity. Sample units can be applied toward future bulk orders upon agreement.

What materials are used in background position systems?

Primary materials include lightweight aluminum alloy for frames, reinforced polyester for backdrops, and stainless steel joints. Premium models use carbon fiber components for reduced weight and increased rigidity. Verify corrosion resistance and load ratings based on intended usage environment.