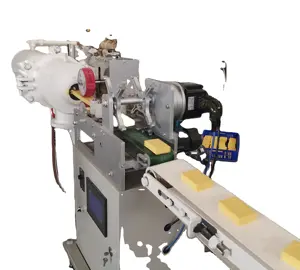

Bar Soap Making Machine Automatic Full Line Producer

Top sponsor listing

Top sponsor listing

About bar soap making machine automatic full line producer

Where to Find Bar Soap Making Machine Suppliers?

China remains the global epicenter for automated bar soap production equipment, with key manufacturing clusters in Henan and Jiangsu provinces driving innovation and cost efficiency. Henan, home to over 40% of China’s chemical processing machinery suppliers, benefits from concentrated industrial ecosystems in Zhengzhou that integrate R&D, fabrication, and logistics. Jiangsu-based manufacturers, particularly around Nantong, specialize in precision automation systems, leveraging proximity to advanced steel and electronics supply chains to reduce component lead times by up to 25%.

These regional hubs support vertically integrated production models—encompassing die casting, CNC machining, control system assembly, and final testing—enabling rapid deployment of full-line solutions. Buyers gain access to scalable infrastructure where machine integration, commissioning, and training can be completed within a single facility network. Key advantages include reduced capital expenditure (15–30% below Western OEMs), lead times averaging 30–50 days for customized lines, and high flexibility for capacity-specific configurations ranging from 100 kg/h to 500 kg/h output.

How to Choose Bar Soap Making Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to ISO 9001 quality management standards as a baseline. For export to regulated markets, CE marking is essential for electrical safety and mechanical conformity. Request documentation on motor efficiency ratings, stainless steel grade usage (e.g., SUS304/SUS316), and PLC control systems (Siemens or Allen-Bradley preferred).

Production Capability Verification

Assess supplier infrastructure using these benchmarks:

- Minimum factory area exceeding 3,000m² for full-line assembly

- In-house engineering teams capable of customizing molds, conveyors, and wrapping units

- Integrated testing protocols for extrusion, stamping, and cooling stages

Cross-reference delivery performance (target ≥96%) with response time (≤4 hours) to gauge operational responsiveness.

Transaction & Quality Assurance

Utilize secure payment frameworks with milestone-based disbursements tied to production progress. Prioritize suppliers offering sample validation under real operating conditions. Conduct pre-shipment inspections to verify alignment with technical specifications, including dimensional accuracy of soap molds and PLC interface functionality. Customization feasibility—such as logo embossing, color mixing, and packaging integration—should be confirmed through prototype demonstrations.

What Are the Best Bar Soap Making Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (Min Order) |

|---|---|---|---|---|---|---|---|

| Nantong Sting Co., Ltd. | Jiangsu, CN | Soap Making Machines, Packaging Machines, Sealing Equipment | 100% | ≤4h | 50% | US $320,000+ | $17,000–80,000/set |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Soap Making Machines, Mixing Equipment, Filling Systems | 97% | ≤2h | 31% | US $370,000+ | $1,556–15,000/set |

| Henan Lovo Industry Co., Ltd. | Henan, CN | Soap Making Machines, Chemical Equipment, Construction Machinery | 96% | ≤3h | 23% | US $540,000+ | Data Unavailable |

| Zhengzhou Aden Machinery Equipment Co., Ltd. | Henan, CN | Soap Making Machines, Gluing Machines, Mineral Processing | 100% | ≤3h | - | - | $2,000–9,000/set |

| KAIFENG JASUN INDUSTRY INC | Henan, CN | Soap Making Machines, Mixing Equipment, Packaging Systems | - | ≤1h | - | - | $1,000–5,000/set |

Performance Analysis

Nantong Sting stands out with a 50% reorder rate and full on-time delivery record, indicating strong customer satisfaction and process reliability. Zhengzhou Yize offers mid-range pricing with verified customization capabilities and responsive communication (≤2h). Henan Lovo reports the highest online revenue, suggesting extensive market reach, though its lower reorder rate may reflect less specialized focus. Aden Machinery and KAIFENG JASUN provide entry-level automation solutions at competitive price points, suitable for small to medium producers seeking modular scalability. Buyers prioritizing responsiveness should note that 80% of listed suppliers respond within 3 hours, with KAIFENG JASUN achieving sub-hour engagement.

FAQs

How to verify bar soap making machine supplier reliability?

Validate certifications through issuing bodies and request audit trails covering material sourcing, welding standards, and electrical safety testing. Analyze transaction history for consistent on-time delivery and post-sale support responsiveness. Video audits of production floors and test runs add transparency for remote evaluations.

What is the typical lead time for a full automatic line?

Standard lead times range from 30 to 50 days after design confirmation. Complex configurations with integrated packaging or multi-mold setups may extend to 60 days. Expedited builds are possible with premium fees, reducing timelines by 10–15 days.

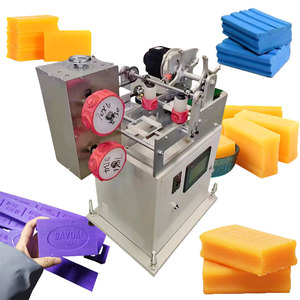

Do suppliers offer customization for mold size and branding?

Yes, most suppliers support custom mold cavities (standard sizes: 80x40x30mm to 120x60x40mm), logo embossing, color dosing systems, and packaging compatibility. Technical drawings and 3D renderings are typically provided within 72 hours of inquiry.

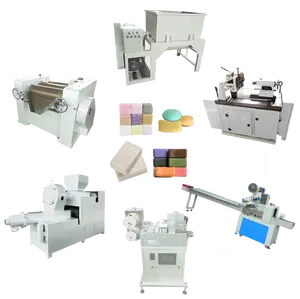

Can machines handle different soap formulations?

Full-line systems are engineered for versatility across toilet soap, laundry bars, and medicated formulations. Confirm compatibility with glycerin-rich, palmate, or tallow-based pastes. Temperature-controlled extruders and adjustable pressing pressures ensure consistent output across raw material variations.

What are common MOQ and pricing structures?

Minimum order quantity is typically 1 set. Pricing varies by capacity: small-scale lines (100–200kg/h) start at $1,000–3,000, mid-range systems (300kg/h) average $15,000–30,000, while fully integrated high-capacity lines exceed $50,000. Bulk orders may qualify for container-load discounts and turnkey installation support.